Hrpo Steel Sheets

Price:

Get Latest Price

Minimum Order Quantity :

05

In Stock

Product Specifications

| Grade | Multiple |

| C % (max) | Varied |

| Mn % (max) | Varied |

| P % (max) | Varied |

| S % (max) | Varied |

| Si % (max) | Varied |

| Al % (max) | Varied |

| YS MPA | Varied |

| UTS (min) | Varied |

| % EL (min) | Varied |

| Hardness (HRb) | Varied |

| Features | Sturdy design, Durable, Rust resistant, Supreme finish |

| Payment Terms | Others, Cash in Advance (CID), Cheque |

| Delivery Time | 07 Days |

| Sample Available | Yes |

| Sample Policy | Free samples are available |

| Main Domestic Market | Delhi |

Product Overview

Key Features

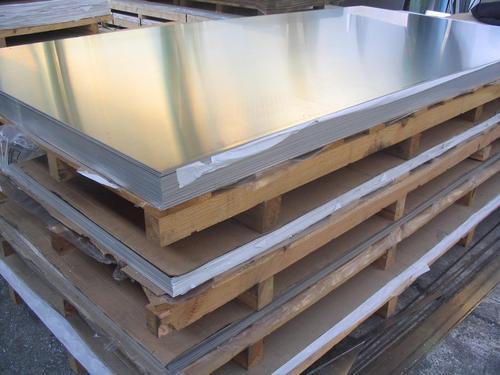

As an affluent firm in this field, we are engaged in offering our esteemed clients with an exceptional quality array of HRPO Steel Sheets. With the help of hot rolled methods, the offered sheets are processed under the stern guidance of adroit professionals using top grade iron alloy. Moreover, the provided sheets are best to be used in automotive industry for fabricating various vehicle parts like body, engines etc. Patrons can easily buy these HRPO Steel Sheets at the most economical prices.

Features:

- Sturdy design

- Durability

- Rust resistance

- Supreme finish

| Application | Cold Rolled Steel | Hot Rolled Steel |

| Auto | Yes | Yes |

| Direct Furniture | Yes | Yes |

| Electrical Panel | Yes | Yes |

| Gen. Engg | Yes | Yes |

| Genset | Yes | Yes |

| Lifts | Yes | Yes |

| Packaging | Yes |

|

| Stamping & Electrical | Yes |

|

| Tubes | Yes | Yes |

Technical Specification :

| Specification | Grade | C % (max) | An % (max) | P % (max) | S % (max) | Si% (max) | Al % (max) | Ppm % (max) | YS MPA | UTS (min) | % EL (min) | Hardness (HRb) | Other |

| Tata | BH 180 | 0.005 max | 0.25-0.35 | 0.02-0.04 | 0.012 max | 0.02max | 0.025 min | 40 max |

|

|

|

|

|

| Tata | DP 420/590 | 0.05-0.07 | 1.3-1.5 | 0.05 max | 0.02 max | 0.40-0.70 | 0.025 min | 70 max | 420 min | 590 min | 90 min |

|

|

|

| IF(HS) | 0.004 | 0.30/0.50 | 0.04/0.07 | 0.012 | 0.02 | 0.02 | 40 |

|

|

| 62 | Ti-0.2 min., Nb-0.04 min |

| Tata |

|

|

|

|

|

|

|

|

|

|

|

| B-0.0005/0.001 Ti-5 min. Nb-0.01/0.015 |

| Tata | IF | 0.0035 | 0.10/0.15 | 0.015 | 0.015 | 0.01 | 0.02/0.06 | 40 |

|

|

| 60 | |

| Tata | EDD | 0.030 | 0.20 | 0.015 | 0.012 | 0.015 | 0.03/0.06 | 50 |

|

|

| 65 Max | |

| US 11513 | EDD | 0.80 | 0.040 | 0.03 | 0.03 |

| 0.02 |

|

|

|

|

| |

|

| DD | 0.10 | 0.45 | 0.035 | 0.035 |

| 0.02 |

|

|

|

|

| |

|

| D | 0.12 | 0.50 | 0.04 | 0.04 |

| 0.02 |

|

|

|

|

|

|

|

| O | 0.15 | 0.60 | 0.055 | 0.055 |

| 0.02 |

|

|

|

|

|

|

| SPFC | 340 | 0.08 | 0.40/0.055 | 0.35/0.05 | 0.02 | 0.04 | 0.25/0.07 | 30/80 |

| 35 Kg/mm2 |

|

| Different % EI (minimum) for different nominal thickness |

|

| 390 | 0.09 | 0.55/0.70 | 0.08/0.10 | 0.02 | 0.04 |

|

|

| 40 Kg/mm2 |

|

| |

| JISG 3131 | SPHE | 0.10 | 0.50 | 0.03 | 0.035 | 0.04 |

|

|

| 270 | 31-41 |

| |

|

| SPHD | 0.10 | 0.50 | 0.05 | 0.05 | 0.04 |

|

|

| 270 | 30-39 |

| |

|

| SPHC | 0.15 | 0.60 | 0.05 | 0.04 | 0.04 |

|

|

| 270 | 29-31 |

| |

| DIN 1614 | st24 | 0.08 | 0.20 | 0.025 | 0.025 |

| 0.02 |

|

|

|

|

| |

|

| st23 | 0.08 | 1.2/0.40 | 0.025 | 0.025 |

| 0.02 |

|

|

|

|

|

|

|

| st22 | 0.10 | 0.02.0.045 | 0.035 | 0.035 |

| 0.02 |

|

|

|

|

| |

| ASTM | A622 | 0.10 | 0.50 | 0.025 | 0.035 |

|

|

|

|

|

|

|

|

|

| A621 | 0.10 | 0.50 | 0.025 | 0.035 |

|

|

|

|

|

|

|

|

|

| A 569 | 0.15 | 0.60 | 0.035 | 0.04 |

|

|

|

|

|

|

|

|

| TaTa GC |

| 0.06 | 0.25 | 0.03 | 0.03 | 0.04 | 0.02 | 90 |

|

|

| 68 max |

|

| TMBP | 1 | 0.05 | 0.025 | 0.02 | 0.02 | 0.03 | 0.02/0.06 | 70 |

|

|

| 5 max |

|

| TMBP | 2 | 0.06/0.090 | 0.025/0.035 | 0.02 | 0.02 | 0.03 | 0.02/0.06 | 80 |

|

|

| 70 max | GL-200mm |

| TMBP | 2 | 0.06/0.090 | 0.025/0.035 | 0.02 | 0.02 | 0.03 | 0.02/0.06 | 80 |

|

|

| 70 max | |

| Bs 1449 | HR-1 | 0.08 | 0.45 | 0.025 | 0.03 |

|

|

| 170 | 290 | 25 |

| |

|

| HR-2 | 0.08 | 0.45 | 0.03 | 0.035 |

|

|

| 170 | 290 | 25 |

| |

|

| HR-3 | 0.10 | 0.50 | 0.04 | 0.04 |

|

|

| 170 | 290 | 21 |

| |

|

| HR-4 | 0.12 | 0.60 | 0.05 | 0.05 |

|

|

| 170 | 280 | 18 |

| |

|

| HR-14 | 0.15 | 0.60 | 0.05 | 0.05 |

|

|

| 170 | 280 | 18 |

|

|

|

| HR-15 | 0.20 | 0.90 | 0.06 | 0.05 |

|

|

| 170 | 280 |

|

|

|

| TISS TRIP | 15 Cr 3 | 0.12/0.8 | 0.40/0.60 | 0.035 | 0.03 | 0.15/0.35 |

|

|

|

|

|

| % Cr=0.40/0.70 |

|

| C-30 (MOD) | 0.29/0.34 | 1.20/1.55 | 0.025 | 0.025 | 0.3 |

|

|

|

|

|

|

|

|

| C-40 (MC-11) | 0.37/0.45 | 0.60/90 | 0.035 | 0.025 | 0.35 |

|

|

|

|

|

|

|

|

| C-45 | 0.40/0.50 | 0.60/90 | 0.035 | 0.025 | 0.35 |

|

|

|

|

|

|

|

|

| C-55(MC11) |

| 0.60/90 | 0.035 | 0.025 | 0.35 |

|

|

|

|

|

|

|

|

| C-62 |

| 0.60/90 | 0.035 | 0.025 | 0.35 |

|

|

|

|

|

|

|

|

| C-75 |

| 0.60/90 | 0.03 | 0.03 | 0.35 |

|

| 40Kg/mm2 | 75 Kg /mm2 | 8 |

|

|

|

| C-80(HC-14) |

| 0.60/90 | 0.035 | 0.025 | 0.35 |

|

| 40Kg/mm2 | 75 Kg /mm2 | 8 |

| % Cr=0.03/0.10 |

| Tata | Elect 1 | 0.02 | 0.3/0.5 | 0.8 | 0.15 | 0.6/0.8 | 0.3/0.5 | 60 |

|

|

|

|

|

| Tata | Elect 1 (M) | 0.02 | 0.20/0.55 | 0.04/0.10 | 0.015 | 0.40/0.60 | 0.20/0.50 | 55 |

|

|

|

|

|

| Tata | Elect 2 | 0.006 | 0.40/0.05 | 0.035 | 0.010 | 0.90/1.10 | 0.30.0.50 | 60 |

|

|

|

|

|

| Tata | Elect3 | 0.01 | 0.40 | 0.05 | 0.012 | 0.90/1.10 | 0.70/1.20 | 50 |

|

|

|

|

|

| Tata | Elect4 | 0.02 | 0.3/0.5 | 0.04/0.1 | 0.15 | 0.2/0.4 | 0.1/0.2 | 60 |

|

|

|

|

|

| Tata | Elect5 | 0.05 | 0.3/0.5 | 0.04/0.1 | 0.2/0.1 | 0.2 | 0.1/0.2 | 80 |

|

|

|

|

|

| Tata | Elect6 | 0.05 | 0.45 | 0.08 | 0.025 | 0.35 | 0.003 | 60 |

|

|

|

|

|

| Tata | Elect7 | 0.0035 | 0.45 | 0.08 | 0.025 | 0.35 | 0.003 | 60 |

|

|

|

|

|

| Tata | Elect8 | 0.02 | 0.3/0.05 | 0.02 | 0.015 | 0.6/0.8 | 0.3/0.5 | 60 |

|

|

|

|

|

| Is 10748 | I | 0.10 | 0.50 | 0.05 | 0.05 |

|

|

| 170 | 290 | 30 |

|

|

|

| II | 0.12 | 0.60 | 0.05 | 0.05 |

|

|

| 210 | 330 | 28 |

|

|

|

| III | 0.16 | 1.20 | 0.05 | 0.05 |

|

|

| 240 | 410 | 25 |

|

|

|

| IV | 0.20 | 1.30 | 0.05 | 0.05 |

|

|

| 275 | 430 | 20 |

| CE=0.45 max |

|

| V | 0.25 | 1.30 | 0.05 | 0.05 |

|

|

| 310 | 490 | 15 |

| CE=0.45 max |

| TIS 340 |

| 0.18 | 0.80 | 0.05 | 0.05 | 0.12 | 0.02/0.08 |

|

|

|

|

|

|

| Tata | PT | 0.06/0.012 | 0.30/0.60 | 0.035 | 0.035 | 0.035 |

| 90 | 195 | 320-480 | 25 |

|

|

| Tata | K1 | 0.08/0.012 | 0.40/0.60 | 0.035 | 0.035 | 0.035 | 0.02 | 90 | 210 | 330-430 | 25 | 72 max |

|

| Tata | K1 (CF) | 0.08/0.012 | 0.4/0.7 | 0.02 | 0.02 | 0.06 | 0.02/0.05 | 90 | 225 | 370 | 35 |

| GL=50 mm |

|

| K3 | 0.18.0.23 | 0.35/0.45 | 0.03 | 0.03 | 0.35 |

|

|

|

|

|

|

|

| Tata | K3 (Special) | 0.10/0.15 | 0.80/1.00 | 0.03 | 0.03 | 0.02 | 0.015 |

|

|

|

|

| MA-0.015 Nominal |

| Tata | K4 | 0.10/0.15 | 0.50/0.70 | 0.025 | 0.025 | 0.1/0.35 |

| 90 | 235 | 360-500 | 24 |

|

|

| JISG 3132 | SPHT-1 | 0.10 | 0.50 | 0.04 | 0.04 | 0.04 |

|

|

| 270 | 30-37 |

| Different %EL |

|

| SPHT-2 | 0.18 | 060 | 0.04 | 0.04 | 0.03 |

|

|

| 340 | 25-32 |

| (Minimum ) for |

|

| SPHT-3 | 0.25 | 0.30/0.90 | 0.04 | 0.04 | 0.03 |

|

|

| 410 | 20-27 |

| Different nominal |

|

| SPHT-4 | 0.30 | 0.30/1.00 | 0.04 | 0.04 | 0.35 |

|

|

| 490 | 15-22 |

| Thickness |

| SAE | 1006 | 0.80 | 0325/0.45 | 0.04 | 0.05 |

|

|

|

|

|

|

|

|

|

| 1008 | 0.10 | 0.30/0.60 | 0.04 | 0.05 |

| 0.02/0.06 |

|

|

|

|

|

|

|

| 1010 | 0.08.0.13 | 0.30/0.60 | 0.04 | 0.04 |

|

|

|

|

|

|

|

|

|

| 1012 | 0.10.0.15 | 0.30/0.60 | 0.04 | 0.05 |

|

|

|

|

|

|

|

|

|

| 1015 | 0.13.0.18 | 0.30/0.60 | 0.04 | 0.05 |

|

|

|

|

|

|

|

|

|

| 1016 | 0.12/0.18 | 0.60/0.90 | 0.035 | 0.035 |

|

|

|

|

|

|

|

|

|

| 1019 | 0.14/0.20 | 0.70/1.00 | 0.05 | 0.05 |

|

|

|

|

|

|

|

|

|

| 1020 | 0.18/0.23 | 0.40/0.60 | 0.05 | 0.03 |

|

|

|

|

|

|

|

|

|

| 1021 | 0.17/0.23 | 0.60/0.90 | 0.05 | 0.05 |

|

|

|

|

|

|

|

|

|

| 1026 | 0.22/0.28 | 0.60/0.90 | 0.05 | 0.05 |

|

|

|

|

|

|

|

|

|

| 1541 | 0.36/0.44 | 1.35/1.65 | 0.05 | 0.03 | 0.35 | 0.07 max |

|

|

|

|

|

|

| ASTMA 53 | A(Type E) | 0.25 | 0.45 | 0.05 | 0.045 |

|

|

| 205 | 330 | As per spec/ |

|

|

|

| B(Type E) | 0.30 | 1.20 | 0.05 | 0.045 |

|

|

| 205 | 415 | As per spec/ |

|

|

| JISG 3101 | SS330 |

|

| 0.05 | 0.05 |

|

|

| 205 | 330-430 | 21:26 |

| Different % EL (minimum) |

|

| SS400 |

|

| 0.05 | 0.05 |

|

|

| 245 | 400-510 | 21:17 |

| For different thickness range |

| APL-5L | A | 0.21 | 0.9 | 0.03 | 0.03 |

|

|

| 207 | 331 | - |

|

|

|

| B | 0.26 | 1.15 | 0.03 | 0.03 |

|

|

| 241 | 413 | - |

|

|

|

| X 42 | 0.28 | 1.25 | 0.03 | 0.03 |

|

|

| 289 | 413 | - |

|

|

|

| X 46 | 0.30 | 1.35 | 0.03 | 0.03 |

|

|

| 317 | 434 | - |

| % RL (minimum) |

|

| X 52 | 0.30 | 1.35 | 0.03 | 0.03 |

|

|

| 358 | 455 | - |

| Different for |

|

| X 56 | 0.26 | 1.35 | 0.03 | 0.03 |

|

|

| 386 | 489 | - |

| Different thickness |

|

| X 60 | 0.26 | 1.35 | 0.03 | 0.03 |

|

|

| 413 | 517 | - |

|

|

|

| X 65 | 0.26 | 1.40 | 0.03 | 0.03 |

|

|

| 482 | 530 | - |

|

|

|

| X 70 | 0.23 | 1.60 | 0.03 | 0.03 |

|

|

| 482 | 565 | - |

|

|

Company Details

Focusing on a customer-centric approach, BANSAL BROTHERS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Steel & Stainless Steel Products & Components in bulk from BANSAL BROTHERS at Trade India quality-assured products.

Business Type

Distributor, Supplier, Trading Company, Wholesaler

Employee Count

20

Establishment

1975

GST NO

07AAAFB5367K1ZC

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 07AAAFB5367K1ZC

New Delhi, Delhi

Mr. Bharat Bansal

Address

Head Office : X-26, Loha Mandi, Naraina, New Delhi, Delhi, 110028, India

Report incorrect details