High Capacity For Aluminum Rod Continuous Casting And Rolling Line - Height: 6.4 Meter (M)

Price: 750000 USD / Set

Get Latest Price

Minimum Order Quantity :

1 Set

In Stock

Product Specifications

| Product Type | Cantilever two roller type rolling system |

| Height | 6.4 Meter (m) |

| Weight | 100000 Kilograms (kg) |

| Length | 50 Meter (m) |

| Usage | produce aluminum rod for wire making |

| Width | 12 Meter (m) |

| Size | Diameter 9.5 mm |

| General Use | Continuous casting and rolling of aluminum rods for cables and conductors |

| Weight (kg) | 100 Tonne |

| Control System | PLC Control |

| Feature | High Performance |

| Color | Multicolor |

| FOB Port | Chongqqing port of China |

| Supply Ability | 3 Per Year |

| Delivery Time | 120 Days |

| Main Export Market(s) | Asia |

| Main Domestic Market | All India |

Product Overview

Key Features

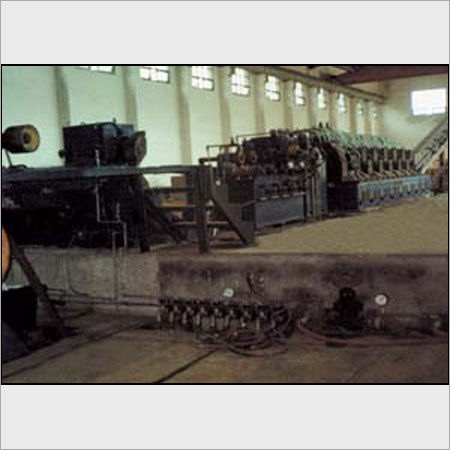

This equipment adopts continuous casting and rolling process to produce round aluminum rod (1A series) for electrical purposes. The diameter of aluminum rod produced is, 12mm, 9.5mm.

2. Simple process flow

2.1 The process flow is shown as follows:

Aluminum water AcA A insulation furnace (user's own)AcA A four-wheel continuous casting machine AcA A front drawing machine AcA A rolling shear machine AcA A Bridge AcA A continuous rolling mill AcA A quadratic curve aluminum rod cooling and lubrication device AcA A double frame continuous rod winding machine AcA A aluminum rod.

2.2 The molten aluminum or the prepared molten aluminum is injected into the four-wheel continuous casting machine through the flow trough of the holding furnace to continuously cast into a trapezoidal ingot with an area of about 3400mm2. The waste ingot is removed by rolling shears, the qualified ingot is fed into the continuous rolling mill to roll out the rod, and the circle is formed by the double frame winding machine.

3. Equipment composition

The unit is mainly composed of four wheel casting machine (integral), front drawing machine, rolling shear machine, bridge crossing device, feeding device, rolling mill system, rolling mill lubricating oil system, rolling mill emulsion circulation system, quadratic curve roller type aluminum rod cooling and lubrication system, double station aluminum rod forming device (concentric circular type and plum type dual-purpose), electric control system of continuous casting and rolling mill.

4. Main technical parameters

1). Crystallization wheel diameter: 2200mm

2). Ingot speed: about 11-15m/min

3). Ingot cross-section: about 3400mm2

4). Casting machine: 5.5kw (AC, variable frequency speed regulation)

5). Continuous rolling mill motor: 1 #, 2 # frame, 3 #, 4 # frame for a single motor independent drive,

The power is 55KW, 75KW, 75KW, 75KW (AC, frequency conversion speed regulation),

5 ~ 14 # frame for centralized transmission, power of 550KW (DC, DC speed regulation)

6). Final rolling speed (Max) : ~ 12m /s (9.5A2 rod)

7). Aluminum rod diameter: A A 9.5mm, 12mm

8). Production capacity: H12, H14 aluminum rod, 7.0-7.5t /h (A 9.5mm electrical round aluminum rod)

9). Number of frames: 14 in total (7 horizontal rollers; Vertical roll stand 7)

10). Pass system: "Ellipse-circle"

11). Roll nominal diameter: 360mm(1 #, 2 # frame), 320mm(3 #, 4# frame), 232mm(5#-14# frame)

12). Coil diameter: 2200mm

13). Take-up weight: 2.0-2.5 tons/basket

Company Details

Focusing on a customer-centric approach, DEYANG BOCHAUNG ELECTROTECHNICAL EQUIPMENT CO., LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Industrial Machinery & Parts in bulk from DEYANG BOCHAUNG ELECTROTECHNICAL EQUIPMENT CO., LTD. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer

Establishment

2005

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Deyang, Sichuan

Mr. Chen Hong Fu

Address

Tianyuan industry development zone, Deyang, Sichuan, 618000, China

heavy machinery in Deyang

Report incorrect details