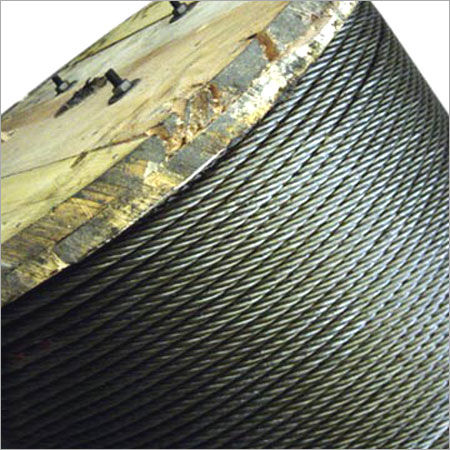

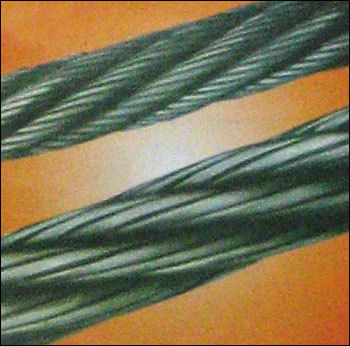

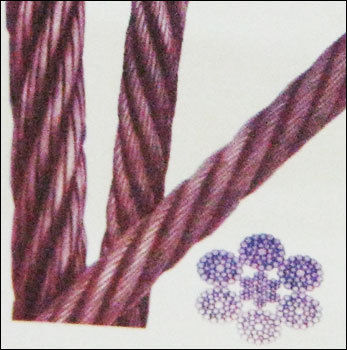

Heavy Duty Steel Wire Rope - Premium Corrosion-resistant Material, Enhanced Tensile Strength And Long-lasting Performance, Safeguarded Against Rust

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel wire |

| Diameter | Variable |

| Length | Customizable |

| Construction | 6x19 |

| Breaking Strength | Specified |

| Coating | Zinc |

| Finish | Galvanized |

| Features | High Tensile Strength, Long Life, Corrosion Resistant, Safe Functionality, Excellent Performance |

Product Overview

Key Features

- Ensure that the correct rope is used.

- Inspect or examine regularly following the rope manufactures guidelines and the recommendation.

- Never overload.

- Minimize shock loading as overstressing of the rope will occur. In order to ensure that there is no slack in the rope at the start of loading, start the load carefully and apply the power smoothly and steadily.

- Avoid sudden loading in cold weather.

- Never use frozen ropes.

- Take special precautions and/ or use a larger sized rope whenever

- Protect rope from sharp corners or edges with padding.

- Avoid dragging the rope from under loads or over obstacles.

- Avoid dropping the rope from heights.

- Avoid rolling loads with ropes.

- The exact load is unknown,

- There is a possibility of shock loading,

- The conditions are abnormal or severe,

- There is a hazard to personnel.

- Store all unused rope in a clean, dry place.

- Never use wire rope which has been cut, badly kinked or crushed.

- Prevent loops in slack lines from being pulled tight and kinking. Once a kink has been made in a wire rope the damage is permanent. A weak spot will always remain no matter how well he kink seems to have been straightened out. If loop forms dont pull it out, unfold it.

- Ensure that the drums and sheaves are of sufficient diameter.

- Avoid reverse bends.

- Repair or replace faulty guides and rollers.

- Ensure the sheaves are aligned and the fleet angle is correct.

- Replace sheaves having deeply worn or scored grooves, cracked or broken rims, and worn or damaged bearings.

- Repair faulty clutches.

- Check for abnormal line whip and vibration.

- Ensure that the rope spools properly on the drum.

- Never wind more that the correct amount of rope on any drum.

- Never allow the rope to cross-wind.

- Ensure rope ends are properly seized.

- Ensure that the ropes do not bind in sheaves. New wire rope requires a run-in period before operating at full load and full speed.

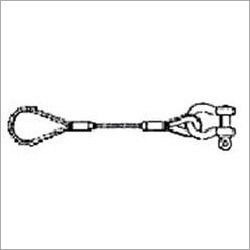

- Use thimbles in eye fittings at all times.

- Lubricate regularly according to the rope manufactures recommendations.

- Watch for local wear. Premature wear at one spot is common and can be prevented if the cause is detected. Uneven wear can be minimized by moving the rope at regular intervals so that different stretches of it are at the critical wear points. Changing layer and crossover points is merely a matter of cutting a few feet of rope from the drum end and fastening it. The cut should be long enough to move the change of layer at least one full coil from its former position and to move the crossover points one-quarter turn around the drum. Move the static section on an equalizer sheave three sheave diameter lengths away by cutting off the section on the drum end of the rope. To distribute wear due to vibration, cut off a section next to the anchorage and refasten the rope.

Company Details

Asahi Ropes is at the frontier of delivering high quality steel wire rope slings and steel rope solution catering to small, medium to large enterprises ,heavy industry, metal & mining, coal drilling, iron ore mining, marine engineering, shipping industry, construction and real-estate among others. We at Asahi believe in the philosophy Dont think of good, when you can achieve best. We amicably work with our highly talented research engineers to ensure a balance between quality and affordability. With their shaper talent and skills, they put in their concerted efforts to ensure utmost level quality standards. We at Asahi believe in having direct communication with our valuable clients as they are directly associated with our end products.

Business Type

Exporter, Manufacturer, Service Provider, Supplier, Producer

Employee Count

100

Establishment

1986

Working Days

Monday To Sunday

GST NO

07AAACA1272B1ZE

Certification

ISO(9001 âÃÂà2008)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 07AAACA1272B1ZE

Delhi, Delhi

Manager

Mr Amit Mishra

Address

Office No.- 902, KLJ Tower, Netaji Subhash Place, Pitampura, Near T.V Tower, Delhi, Delhi, 110034, India

steel wire ropes in Delhi

Report incorrect details