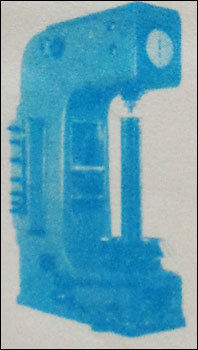

Hardness Testing Machine - Rockwell Testing Capability, 110x55mm Test Height | Adjustable For Various Applications, Adheres To Is: 1586-2000 Standards

Price:

Get Latest Price

In Stock

Product Specifications

| Type | Rockwell |

| Scales | HRA, HRB, HRC |

| Indenters | Diamond, Ball |

| Test Height | 110 mm |

| Throat Capacity | 55 mm |

| Standard | IS: 1586-2000 |

| Usage | Hardness testing of various materials, especially those difficult to test with standard table-top models. |

| Material | Aluminum Alloy |

| Weight | 2kg |

| Features | Portable, Accurate, Efficient, Versatile, Compact |

Product Overview

Key Features

Backed by well equipped & advanced machinery, our company is known amongst the pioneer manufacturers and exporters of Hardness Testing Machine. Our expert procuring agents obtain high-end quality materials from authentic vendor base to manufacture these machines as per industrial standards. Widely used in diverse industries to check the hardness of different materials, our Hardness Testing Machine is highly appreciated among our clients due to its excellent efficiency, accurate measurement and fine finish.

Further Details:

FSM portable Rockwell Hardness Tester is developed to meet the demands of a light weight instrument which can be used to carry out tests by a universally recognized method of hardness testing. This hardness tester can be used in variety of applications and is readily adjustable to a wide range of sizes and shapes which are difficult to test in a standard table model hardness tester

Salient Features

- One of the features includes a maximum test height x throat capacity of 110 x 55 mm

- Its Rockwell hardness scales such as HRA, HRB and HRC are obtained by using different types of indenters namely Diamond or Ball

- It conforms to IS: 1586-2000 for Rockwell test as per international standards

- This hardness tester can be used in variety of applications and is readily adjustable to a wide range of sizes and shapes which are difficult to test in a standard table model hardness tester

- The machines designed for carrying out Rockwell tests comparable to table model hardness tester because, the basic things, such as shape of penetration, measurement and loads are same in both systems

- The photograph on the back side gives the general arrangement of the hardness tester

- The system carries a weight bar pivoted at central point. When the load is applied by the loading screw, at one end of this weigh bar, it is deflected and the other end of this bar carrying penetrator forces down into the test specimen. This deflection of weight bar which is proportional to the applied load is indication of the loading dial indicator. Besides this loading dial indicator, there is one penetration measuring indicator which measures the actual penetration of the penetrator into the test specimen. The hardness value of the specimen is read directly on this indicator

Company Details

Focusing on a customer-centric approach, FIVE STAR MANUFACTURING has a pan-India presence and caters to a huge consumer base throughout the country. Buy Testing & Measuring Equipment in bulk from FIVE STAR MANUFACTURING at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Establishment

2008

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Ichalkaranji, Maharashtra

Accepts only Domestic inquiries

Partner

Mr. Rahul Ravande

Address

20/22, Near A.S.C. Collage, Behind Gajare Karkhana, Ichalkaranji, Maharashtra, 416115, India

hardness testing machine in Ichalkaranji

Report incorrect details