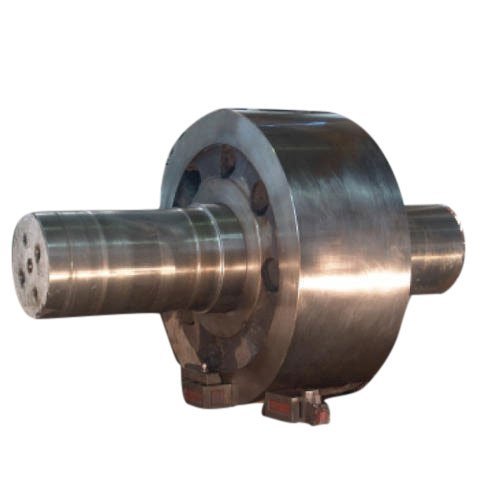

Red Girth Gear Casting

Price: 100 INR / Kilograms

Get Latest Price

Minimum Order Quantity :

500 Kilograms

In Stock

Product Specifications

| Surface Treatment | Polished |

| Product Type | Iron Castings |

| Material | Iron |

| Surface | Polished |

| Application | Girth Gear Casting |

| Color | Red |

| Supply Ability | 60000 Per Month |

| Delivery Time | 7 Days |

| Main Domestic Market | All India |

Product Overview

Key Features

Girth gears (ring gears) are large ring gears that are normally fitted to the outside of ball mills or rotary kilns to provide the primary rotational drive, which is required to be operated for a long time, so the quality requirements during the actual production for the big gear ring are very high Girth gears are applied in various types of horizontal mills, rotary dryers, and rotary kilns

Advantages

1. Special Heat Treatment Technology

Great Wall Steel Casting adopts special heat treatment technology to optimize structure, improve hardness and enhance impact resistance of girth gear.

2. Long Service Life

Great Wall Steel Casting adopts high strength steel to produce girth gear. Firstly characteristics optimization of rotary kiln is done to guarantee its stability during long time operation, also to prolong its working life.

3. Factory Price Custom & Quick Delivery

Great Wall Steel Casting has strong steel casting production capability, and it can provide girth gear in large quantity with short period.

Girth Gear (Rotary Kiln or Ball Mill) Quality Testing:

Girth gear rim is casted in two halves

Non destructive testing is performed to ensure zero defects

Machining of gear in multiple steps to ensure best finish and accuracy

Final quality inspection to ensure CPG quality

Specification

Specification

Item

Casting Steel Girth Gear

Pressure angle

Customized

Material

Alloy steel & Carbon steel

Application

rotary kiln, ball mill, rotary dryer,etc.

Packing

Seaworthy plywood packaged on stell pallets or as customers request

Delivery date

Depends on the amount and dimension of products

Why quality is so important?

Total Girth Gear installation cost survey

Calculation example:

Kiln size 5.0 x 90 m Production: 4500 tpd

Estimated cost of parts: EUR 450.000,- (27%) Girth gear + springs etc.

Est. mech. erection costs: EUR 130.000,- (8%) 29% of parts cost

Estimated consequential loss : EUR 1.080.000,- (65%) EUR 4500/hour in 10 days

Total installation costs: EUR 1.660.000,- (100%) Parts 27% Consequential 65% Mech. 8%

Conclusion:

The cost of the Girth Gear is only a "piece of the cake compared with the total substantial installation cost.

Long term solution with Great Wall Casting quality is the best solution to ensure a beneficial investment.

How to Install the girth gear(rotary kiln):

The girth gear is placed near to a kiln tyre so that it is accurately aligned with the rotary kiln axis, with minimal wobble. It is normal for the nearby tyre to be fixed in position with thrust rollers, so that as the kiln expands on warming up, the turning girth gear position remains fairly constant, while the nose and tail of the kiln expand outward.

Company Details

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

55

Establishment

2003

Working Days

Monday To Sunday

GST NO

24AADFD8606L1ZD

Payment Mode

Online Payments (NEFT/RTGS/IMPS)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24AADFD8606L1ZD

Halol, Gujarat

Manager

Ms Riddhi Rajani

Members since

3 Years

Address

Plot No. 1706/9-11, G.I.D.C. Estate, At & Po. Halol, Dist. Panchmahal, Halol, Gujarat, 389350, India

Report incorrect details