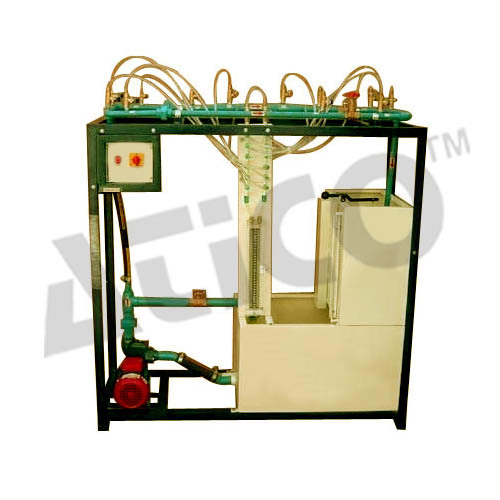

Gas Flow Classification - Zigzag Sifter 1500mm, Cyclone 550mm Diameter, Max Mass Flow 10kg/h | Coarse & Fine Material Separation, Air Flow Measurement, Pressure Loss Monitoring

Price:

Get Latest Price

Minimum Order Quantity :

1 Piece

Brand Name :

Teknik

In Stock

Product Specifications

| Temperature Range | -20AdegC to 80AdegC |

| Automation Grade | Automatic |

| Voltage | 220 V |

| Model No | GF-1000 |

| Product Type | Gas Flow Classification |

| Application | Mechanical Process Engineering |

| Accuracy | A+-1% F.S. |

| Usage | Mechanical Process Engineering |

| Feature | High Accuracy, Real-time Monitoring |

| Power Source | Electric |

| Measurement Range | 0-1000 m3/Hr |

| Core Components | Flow Sensor, Controller |

| Frequency | 50 Hz |

| Capacity | 1000 m3/Hr |

| Equipment Materials | Stainless Steel |

| Type | Gas Flow Classification |

| Display Type | Digital |

| Dimension (L*W*H) | 1200 mm x 800 mm x 1600 mm |

| Weight | 150 kg |

| Payment Terms | Cash Advance (CA), Cash in Advance (CID), Cheque, Telegraphic Transfer (T/T), Letter of Credit (L/C) |

| Sample Available | Yes |

| Sample Policy | Sample costs shipping and taxes has to be paid by the buyer |

| Packaging Details | carton box, export quality also available |

| Main Domestic Market | All India |

| Certifications | ISO 9001, 14001 ,CE |

Product Overview

Key Features

Micro Teknik - learning the fundamental principle of wind sifting

(gas flow classification)

- sorting

* coarse material fraction

* fine material fraction

dependent on solid mass flow rate and volumetric

air flow rate

- classifying

* fraction balance

* separation function

* separation size

* sharpness of separation

dependent on solid mass flow rate and volumetric

air flow rate

- pressure losses of

* sifter

* cyclone

dependent on solid mass flow rate and volumetric

air flow rate

Specification

[1] zigzag sifter to separate solid compounds

[2] feed hopper with vibrating trough for feed of solid compound into sifter

[3] dosage of feed material by way of distance of hopper outlet from vibrating trough and frequency of vibrating trough

[4] separation of solid compound into coarse and fine material with air flow in 20-stage zigzag duct

[5] air flow generation by fan; adjustment by valve

[6] separation of fine material from air flow by gas cyclone with tangential inlet

[7] 3 tanks for feed material and coarse and fine materials

[8] recording of volumetric air flow rate and differential pressure through sifter and cyclone.

Technical Data

Vibrating trough

- mass flow: max. 10kg/h

- vibration frequency: max. 3000min-1

Zigzag sifter

- height: approx. 1500mm

- cross-sectional area: 40x50mm

Cyclone

- height: approx. 550mm

- diameter: 150mm

Fan

- volumetric flow rate: max. 600m/h

- power consumption: approx. 3600W

Tanks

- feed hopper: 3L

- coarse material: 2L

- fine material: 2L

Measuring ranges

- cyclone and sifter differential pressures: 0...100mbar

- volumetric flow rate (air): approx. 10...100m/h

Company Details

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

25

Establishment

1973

Working Days

Monday To Saturday

GST NO

06ACMPJ7244B1ZS

Certification

ISO 9001 : 2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 06ACMPJ7244B1ZS

Ambala Cantt, Haryana

Ceo

Mr Vikas

Members since

13 Years

Address

Plot No. 73, Vikaspuri, Industrial Area, Ambala Cantt, Haryana, 133001, India

fluid mechanics lab in Ambala Cantt

Report incorrect details