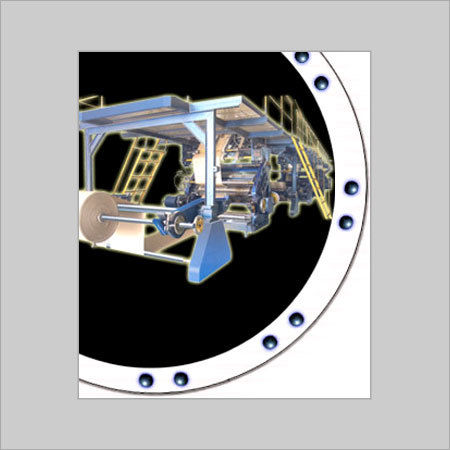

Fully Automatic Inline One Pass Pmb And Crmb Plant

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel, Ss |

| Dimensions | Customizable |

| Capacity | Variable |

| Power | 3-Phase |

| Control | Plc-Based |

| Sensors | Level, Flow |

| Homogenizer | High Shear |

| Features | Inline System, High Shear, Plc Control, Easy Operation, Recipe Storage, Precise Dosage, Overfill Prevention, Quick Changeover, Low Labor Cost, High Utilization, Mobile Operation |

Product Overview

Key Features

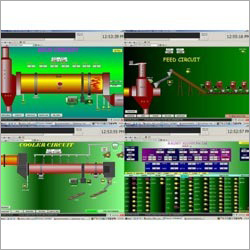

AMT TECHNOa s Fully Automatic Inline One Pass Type PMB/CRMB Plant is useful to customers who have large requirement market. In Inline One Pass System, bitumen directly come from the storage and dose to the 1,000 litters premixing tank by pump, premixing tank is equipped with agitator for premix bitumen, at same time polymer or crumb rubber is dose in premixing tank by screw conveyor both ratio are controlled by PLC based control panel. The other side one pump connected to premixing tank outlet, it is dosing bitumen and polymer or crumb rubber to Hi Shear Homogenizer. Pump is controlled by Level Transmitter which is installed in the premixing tank.

Advantage of Inline One Pass system:

a.Continues production, useful to large requirement market

b.Hi Shear Homogenizer which is ensure small partial size

c.PLC Based control panel which gives very Easy Operation of Equipment.

d.Recipe can be save and store for future

e.Coriolis mass flow meter for Bitumen.

f.Flow meter is ensuring the highly precision dosage.

g.Radar Level Transmitter for monitor premixing tank level for prevents the system to overfill.

h.Quick change from one to another

i.Less labor and lower handling costs are required

j.Higher utilization by elimination of the time required to prepare for batch

k.Built in a container and mounted on the trailer for mobile operation

Company Details

We are an India’s leading manufacturer of Bitumen Processing Equipments. We offer comprehensive process solutions for Bitumen Emulsion, Polymer Modified Bitumen, Crum Rubber Modified Bitumen, Bentonite Clay Emulsion, etc. across a wide range of Application in Road, Roofing and Many More. AMT TECHNO is optimizing processes with regards to economic efficiency, safety and environmental protection.

Business Type

Exporter, Manufacturer

Employee Count

11

Establishment

2008

Working Days

Monday To Saturday

GST NO

24AJGPC8234R1ZV

Payment Mode

Online Payments (NEFT/RTGS/IMPS), Cheque/DD, Wallet & UPI, Cash

Certification

ISO 9001:2015, CE

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24AJGPC8234R1ZV

Vadodara, Gujarat

Proprietor

Mr. Harshkumar Chitroda

Members since

1 Years

Address

23, Durga Industrial Estate, Near Jain Temple, NH-08, Sankarda, Vadodara, Gujarat, 391350, India

sponge iron plant in Vadodara

Report incorrect details