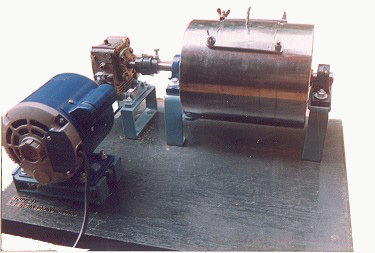

Colloidal Mill - High-speed Rotor And Stator Design For Effective Wet Mixing, Dispersion, Emulsification, And Homogenization In Diverse Industries

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless Steel |

| Power | 3-100Kw |

| Speed | 3000-10000 Rpm |

| Capacity | 10-10000 L/Hr |

| Dimensions | Variable |

| Gap | 0.01-0.5 Mm |

| Stages | 1-5 |

| Features | High Efficiency, Precise Mixing, Easy Operation, Durable Design, Versatile Use, Cost Effective, Reduced Waste |

Product Overview

Key Features

Colloidal Mill is work on the rotor and stator principal, Rotor and Stator is designed coaxially stages, which have radial slotted and a unique designed tooth was created. Design of rotor and stator, number of stages, number of tooth and material of Rotor and Stator are depending on the application data lick media viscosity, specific gravity, hardness, temperature, composition etc. Colloidal mill mainly designed as stator is fixed and rotor is rotating at hi speed (RPM), speed is also depending on the application. The media is entered in the system from the center of stator, because of high speed a centrifugal force is created and media is flow the outside from stages of rotor and stator where minimum gap between rotor and stator is ensure the proper mixing and homogenizes of liquid or solid.

AMT TECHNO is developed a unique combination of rotor and stator for Bitumen Emulsion and PMB/CRMB which give the proper partial size distribution and better result in the final product.

Company Details

We are an India’s leading manufacturer of Bitumen Processing Equipments. We offer comprehensive process solutions for Bitumen Emulsion, Polymer Modified Bitumen, Crum Rubber Modified Bitumen, Bentonite Clay Emulsion, etc. across a wide range of Application in Road, Roofing and Many More. AMT TECHNO is optimizing processes with regards to economic efficiency, safety and environmental protection.

Business Type

Exporter, Manufacturer

Employee Count

11

Establishment

2008

Working Days

Monday To Saturday

GST NO

24AJGPC8234R1ZV

Payment Mode

Online Payments (NEFT/RTGS/IMPS), Cheque/DD, Wallet & UPI, Cash

Certification

ISO 9001:2015, CE

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24AJGPC8234R1ZV

Vadodara, Gujarat

Proprietor

Mr. Harshkumar Chitroda

Members since

1 Years

Address

23, Durga Industrial Estate, Near Jain Temple, NH-08, Sankarda, Vadodara, Gujarat, 391350, India

colloid mill in Vadodara

Report incorrect details