Frp Lining Services - Durable Fibre-reinforced Plastic Coating | Leak Proofing, Anti-corrosion, Chemical Resistance, Expert Application

Price:

Get Latest Price

In Stock

Product Specifications

| Material | FRP |

| Resin Type | Polyester/Vinyl ester |

| Reinforcement | E-glass |

| Coating Type | Epoxy |

| Application Method | Brush/Roller |

| Usage | Tank lining, leak proofing, anti-corrosion treatment for various industries. Ideal for rooftops and chemical tanks. |

| Surface Prep | Sandblasting |

| Features | Corrosion resistance, Leak proofing, Durable, Cost effective |

Product Overview

Key Features

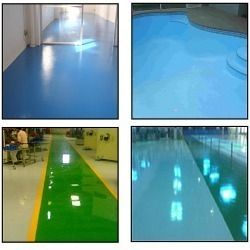

Our organization offers reliable services of FRP

(Fibre-reinforced plastic ) Lining to our customers. These

services are rendered by our highly skilled professionals, who have

immense expertise in their respective domains. Our offered services

is widely used in diverse applications such as leak proofing of roof

tops, tank lining in chemical industries, anti corrosion treatment of

metal tanks and many more. These services are capable to withstand

harsh conditions, thus widely demanded in various industries.

Safety:

The tank to be lined should be

thoroughly emptied and cleanVapor in the tank should be purged to reduce

inhalation hazards

Surface Preparation:

Concrete

Holes in the floor greater than an

inch diameter are repaired by welding metal plates over them and

patched by puttyCheck the moisture contents with

moisture meter, to make sure an ideal moisture 4% - 10% MaxMetal

The surface must be free of scale,

oil and greaseSand blast to near white color

Prime the clean surface:

The metal and concrete surface are protected by brushing on a

epoxy resin Duracoat-009-PD and Hardener Duracoat-40-H, to increase

bonding strength between FRP to metal and concrete

Apply The Laminate:

All areas to be lined with Glass

Mat and Polyester or vinyl ester resin as specifiedThe standard of glass is E glass

that would be reinforcement layerThe resin and glass are to be

worked down with special groovedRoller and brushes in order to minimize the surface free of

pin holes and air pockets

Apply the corrosion barrier:

After apply the laminate as reinforcement layer, surfacing

veil as the corrosion barrier should be applied with polyester or

vinyl ester as specified

Spark test:

Before applying the finish coat,

all surface to be inspected to found any pin holes with spark test

machineAny pinholes detected and found, would be repaired at this

time

Finish coating & hardness test:

Polyester and vinyl ester

finishing coating would be brushed on the surface, mix the resin

with wax additive and pigment color as specifiedMake sure the hardness surface with barcol harness test

machine

Company Details

Focusing on a customer-centric approach, ARJUNAN ENTERPRISES has a pan-India presence and caters to a huge consumer base throughout the country. Get Others from ARJUNAN ENTERPRISES at Trade India quality-assured services.

Business Type

Exporter, Importer, Manufacturer, Service Provider, Supplier

Employee Count

50

Establishment

2005

GST NO

33AMUPP8423E2ZQ

More Product From This seller

Seller Details

GST - 33AMUPP8423E2ZQ

Chennai, Tamil Nadu

Proprietor

Mr. A. Pasumalai

Address

No. 34-A, Rajiv Gandhi Salai, Thanthai Periyar Nagar, Alwarthiru Nagar, Chennai, Tamil Nadu, 600087, India

frp lining services in Chennai

Report incorrect details