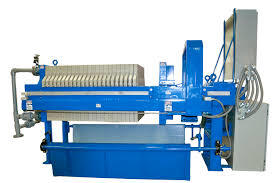

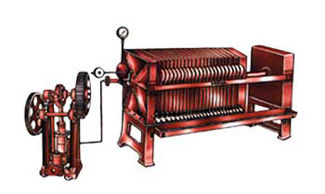

Frame Filter Press - Stainless Steel, Efficient Slurry Separation System | Easy Maintenance, Long Service Life, Precise Design

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel,Pp |

| Dimensions | Variable |

| Capacity | Variable |

| Pressure | Variable |

| Filtration Area | Variable |

| Plate Type | Frame |

| Automation | Manual/Automatic |

| Features | Easy Maintenance, Precise Designs, Long Lifespan, High Efficiency, Durable Build, Cost Effective, Reliable Operation |

Product Overview

Key Features

Related Products

More Product From This seller

Company Details

Arrow Technical Textiles Pvt. Ltd. is a dynamic young company offering world-class composite fibers such as high Strength Fiberglass, High Silica, Carbon Fiber, Basalt Fiber, Aramid, EMI (Electromagnetic Induction) and ESD (Antistatic fabric) Fibers, and Filtration Media. Our Business Verticals : INSULATION TECH ENVIRON-TECHBUILD-TECH PRO-TECH ADVANCED COMPOSITEALL TYPES OF FIBRES

Business Type

Manufacturer, Supplier

Employee Count

12

Establishment

2013

Working Days

Monday To Saturday

GST NO

27AAMCA0628H1ZQ

Explore Related Categories

Seller Details

GST - 27AAMCA0628H1ZQ

Mumbai, Maharashtra

Sales

Mr Pragnesh Mistry

Members since

1 Years

Address

C-216, Akurli Ind. Estate, 2nd Floor, Akurli Road, Kandivali East, Mumbai, Maharashtra, 400101, India

industrial filter press in Mumbai

Report incorrect details