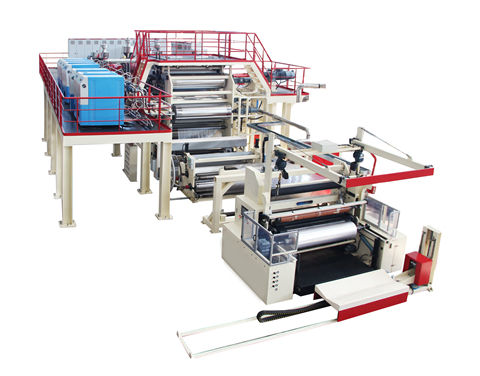

Fully Automatic Four-shafts Roll Change Cast Stretch Film Production Line - Steel Alloy, Maximum Winding Diameter 350mm, Line Speed 380m/min | High Efficiency, Low Energy Consumption, Simple Control, One-person Operation

Price: 30000 USD / Unit

Get Latest Price

Minimum Order Quantity :

1 Unit

In Stock

Product Specifications

| Product Type | Automatic Cast Stretch Film Production Line |

| General Use | Used for high-efficiency production of stretch films with automatic roll change for continuous operation |

| Material | Steel Alloy |

| Automatic | Yes |

| Surface Treatment | Polishing |

| Feature | High Efficiency, Simple Control, Stable Operation, High Performance, Lower Energy Consumption |

| Color | White |

| Warranty | 1 Year |

| Payment Terms | Telegraphic Transfer (T/T) |

| Supply Ability | 15 Per Year |

| Delivery Time | 45 Days |

| Packaging Details | Standard packaing |

| Main Export Market(s) | Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe |

| Main Domestic Market | All India |

Product Overview

Key Features

Human-machine interface integration, controlled by Siemens PLC.

Fully automatic loading and unloading technology adopts independently developed mechanical systems, software systems, and intelligent temperature control systems to achieve 10 automations: automatic roll change, automatic film unloading, automatic tube loading, automatic deflation, automatic inflation, automatic film loading, automatic recycling, automatic monitoring, automatic weight replenishment, and automatic feeding.

Negative pressure compensation technology: The film is instantly attached to the cooling roller with zero gap for cooling and forming to avoid film surface defects.

High-speed screw melting technology (technical cooperation with an Italian company, learning from foreign separation screw technology) to achieve ultra-high plasticization, super transparency, and increase the technical volume by more than 30%.

Rapid cooling and shaping technology (the surface temperature difference of the cooling roller is <= A A A A 1A A A A C and the transverse and longitudinal tensile force is increased by more than 20%).

Design line speed: 380 m/min. Maximum winding diameter: 350 mm. One person operation. One-button speed increase.

Vacuum air shift edge automatic recovery device, not easy to block the material, not easy to break the edge, to ensure that the production is not limited by the winding speed limit. Designed for the high-speed machine recycling edge material stability. Optional online granulation machine.

Machine Highlights:

High working speed: 250~300 M/min.

High production capacity: 400~500 KG/H (depends on the film thickness and line speeds).

Wintech T-die or JC-Time T-die (optional), Automatic T-die (optional), Thickness Scanner (optional).

Excellent production capacity and power consumption ratio: around 0.4 KWH/KG.Easy to operate, one man is enough!

Automatic paper cores loading & unloading system, fully automatic, saves much labor cost.

Our Advantages:

The main motor and gearbox are connected by Martin coupling. It has better shock absorption effect and lower noise.

The alloy screw and barrel are well nitrided. The screw heating adopts segmented independent heating control, and each segment is controlled by a fan, which makes the temperature control more precise.

Optional hydraulic screen changer. It is easier and more convenient to replace the filter.

Main cooling roller with a diameter of 980 mm. The double-layer spiral design ensures that the cooling water passes through the roller surface completely to achieve the best cooling effect.

All cylinders, solenoid valves, sensors, thermostats, and other electrical parts are all original.

Company Details

Dongguan Wintech Plastic Machinery Co., Ltd. is an intelligent equipment manufacturer focusing on the development and production of automatic stretch film machines and rewinder. Our factory is located in Gaobu Town, Dongguan City, Guangdong Province which covers 3,000 square meters. Our main products are stretch film machines and rewinders, including stretch film rewinding and slitting machines, pre-stretched film rewinder and aluminum foil rewinder. Products have been widely used in many fields such as industry, packaging, food, logistic transportation, daily chemicals and so on. All of our products are exported to Southeast Asia, the Middle East, Africa, Europe, America and other parts of the world. We provide pre-sales consulting and after-sales maintenance services in Vietnam, India, Egypt, Turkey, Pakistan, Mexico, the United States and other countries. Since we established in Hong Kong in 2013, Wintech has fully introduced and absorbed foreign advanced technology that has continuously improved the intelligence of our equipment. We have successively obtained a number of national patents, leading the domestic industry. Wintech mission-Continuous innovation for customers to improve efficiency; Wintechvision-based in China, looking at the world, building into an internationally competitive enterprise.

Business Type

Exporter, Manufacturer, Supplier, Producer

Employee Count

100

Establishment

2013

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Dongguan, Guangdong

Mrs Yuan Yuan

Address

101, Building 3, No. 3, Zhonglong 2nd Road, Gaobu Town, Dongguan, Guangdong, China

Report incorrect details