Flue Gas Desulphurization Systems - Carbon Steel, Ventury Scrubber / Spray Tower / Packed Tower / Tray Column | High Efficiency Mist Eliminator, Low Pressure Drop, Advanced Control Instruments

Price:

Get Latest Price

In Stock

Product Specifications

| Construction | Venturi/Spray |

| Handling Media | Flue Gas |

| Scrubbing Media | Limestone |

| Material | Carbon Steel |

| Operation | Recirculation |

| SO2 Removal | 92% |

| Usage | Power plant emission control, removing sulfur dioxide from flue gases of fossil-fuel power plants and other sulfur oxide emitting processes. |

| Features | SO2 Reduction, High Efficiency, Robust Design, Wide Range, Customizable, Cost-Effective |

| FOB Port | JNPT Port |

| Supply Ability | Customize |

| Packaging Details | As per client requirement. |

| Main Export Market(s) | North America, Central America, Middle East, South America |

Product Overview

Key Features

We are the leading manufacturer and supplier of supreme

quality range of Flue Gas

Desulphurization Systems. These are manufactured by our team using optimum

quality materials in accordance with defined industry norms. The offered systems

are used to remove sulfur dioxide (SO2) from exhaust flue gases of fossil-fuel

power plants as well as from the emissions of other sulfur oxide emitting

processes. Furthermore, the customers can avail these Flue Gas Desulphurization Systems from us at affordable prices.

Features:

- High in strength

- Robust design

- Excellent durability

GENERAL DESCRIPTION AND SPECIFICATION

We have been widely appreciated in the market for providing supreme qualityof FGD systemsto the customers. These products are highly demanded by the clients for their effective usage in large scale industries. The entire range is assembled using quality-tested components, under the expert guidance of our team of experienced professionals.

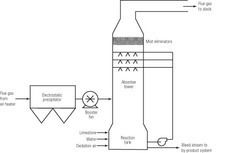

Whizz offers a wide range of FGD systems according to the customer requirement. TheFGDtechnology is based on a chemical reaction that occurs when the warm exhaustgasesfrom the coal-fired boiler come into contact with limestone. This reaction removes 92% of the sulphur dioxide from theflue gasand converts the limestone into Calcium Sulphite.

Classically scrubbers are classified according to application and structural design namely Spray Tower, Tray tower, Packed Bed Scrubber and Ventury Scrubber. The reason for many scrubber failures is very low turndown ratio and poor operating range. Also other problem relating of scrubbers are scaling, corrosion, poor spray patterns, poor wetting of packing(channelizing), non proper gas distribution in Ventury etc., We studied all these factors and problems and developed scrubber design which will take care of all these points.

We first simulate the design, study the flow patterns, correct if any and then prepare final design. With this the scrubber will operate satisfactory in the given operating range. We also offer separate slurry preparation system for scrubbing media so that we will get more efficiency with same system.

Technical specifications:

1. Construction: Ventury Scrubber / Spray Tower / Packed Tower / Tray Column.

2. Handling media: Flue gas / Contaminated Air.

3. Scrubbing media: Water / Caustic / Lime / Limestone / Magnesium Oxide / Dual Alkali / Hydrogen peroxide etc.

4. Material of Construction: Carbon Steel / AISI 304 / AISI 316 / FRP / Custom Made.

5. Operation: Once through / Recirculation.

Exclusive Features:

- Simulated design with flow characteristic simulation.

- Very high turndown ratio hence wider operating range.

- Separate slurry preparation system with agitator and homogenizer which enhances the scrubbing efficiency.

- Highly efficient Mist eliminator with more vapor disengagement space to avoid moisture carryover.

- Provision for mist eliminator cleaning and washing.

- Separate Forced Oxidation tank with provision for mechanical/air agitation for none scaling.

- Low pressure drop per unit length of scrubber, hence lower operating cost.

- Incorporated with latest instruments like flue gas analyzers, pH sensors, turbidity meters etc. for easy and trouble free operations.

- Necessary interlocks and control for long life of equipments.

- Most uniform gas distribution with rotary vane design and hence largest mass transfer coefficient.

- Very special unique non clogging nozzles for scrubbing media distribution.

- Complete system is engineered to avoid scaling, chocking, and corrosion in system.

- Consistent quality of slurry hence disposal becomes more convenient.

Company Details

Focusing on a customer-centric approach, WHIZZ ENGINEERING SERVICES PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Get Pollution Control & Monitoring Equipment from WHIZZ ENGINEERING SERVICES PVT. LTD. at Trade India quality-assured services.

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

10

Establishment

1999

Working Days

Monday To Sunday

GST NO

27AAACL8654J1Z4

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AAACL8654J1Z4

Pune, Maharashtra

Product Incharge

Mr. Rohit

Address

Survey No. 15/1, Gujarwadi Road, Katraj Nagar, Pune, Maharashtra, 411046, India

flue gas cleaning system in Pune

Report incorrect details