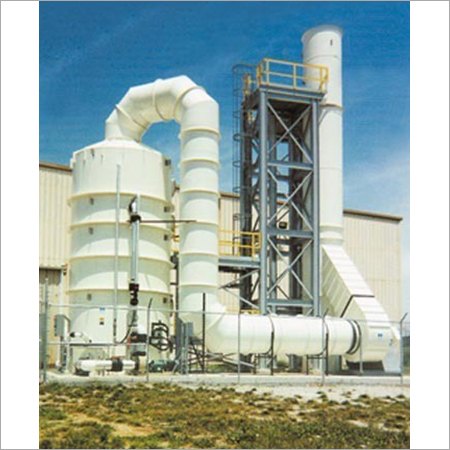

Venturi Scrubber System Machine

Price:

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Material | Stainless steel |

| Dimensions | Variable |

| Scrubber Media | Water/Caustic |

| Gas Handling | Flue gas |

| Operation Mode | Recirculation |

| Efficiency | 99% |

| Usage | Flue gas/contaminated air scrubbing in industrial settings |

| Features | High efficiency, Low maintenance, Customizable, Reliable operation, Wide range |

| Payment Terms | Cash on Delivery (COD), Cheque, Cash Against Delivery (CAD), Days after Acceptance (DA), Cash in Advance (CID) |

| Sample Available | Yes |

| Sample Policy | Contact us for information regarding our sample policy |

| Main Domestic Market | Maharashtra |

Product Overview

Key Features

Its Product Details are:

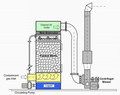

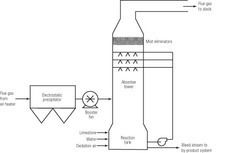

Handling media : Flue gas / Contaminated Air

Scrubbing media : Water / Caustic / Lime / Limestone / Magnesium Oxide / Dual Alkali./Hydrogen Peroxide, etc

Material of Construction : Carbon Steel / AISI 304 / AISI 316 / FRP / Custom Made.

Operation : Once through / Recirculation

We first simulate the design, study the flow patterns, correct if any and then prepare final design. With this the scrubber will operate satisfactory in the given operating range. We also offer separate slurry preparation system for scrubbing media so that we will get more efficiency with same system

Dust/Fume Extraction System:

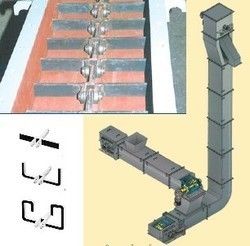

In thermal power stations, Metal Industry, Coal/material conveying is one of the most important . Coal/Material handling system mainly consists of unloading, screening, crushing, stacking, reclaiming and bunker feeding equipment arranged in an optimum configuration. Coal or bulk solids are received at site either by ships or by rail-wagons or by trucks. It is then conveyed for screening and crushing. For smaller capacity plants, either conveyor with traveling tripper or conveyor with telescopic chute is generally used for stacking the crushed coal andreclaimed using bridge type scraper reclaimer or underground reclaim hopper with suitable capacity dozers.

Dust generation in a plant:

Loading point, Unloading point of belt conveyor, Discharge Chutes: Dust from the operation of belt conveyors originates mainly at the trail pulley where material is received and at the head pulley where material is discharged. Dust generation depends on belt width, speed, height of fall of coal.

Bunker Feeding Point: Crushed coal either directly from crushers or from the crushed coal stockyard is conveyed to boiler bunkers through traveling trippers or reversible shuttle conveyors. Dust is generated while loading the bunkers, spreading of which is controlled to some extent by conveyor sealing arrangement, and needs to be extracted from bunkers.

Crusher area: Crushers are used for size reduction in the coal or other particle. The huge gyratory or roller crushers are used for primary size reduction, while jaw or gyratory crushers are used for secondary size reduction. Large side hoods are used for dust extraction.

Company Details

Focusing on a customer-centric approach, WHIZZ ENGINEERING SERVICES PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Get Pollution Control & Monitoring Equipment from WHIZZ ENGINEERING SERVICES PVT. LTD. at Trade India quality-assured services.

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

10

Establishment

1999

Working Days

Monday To Sunday

GST NO

27AAACL8654J1Z4

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AAACL8654J1Z4

Pune, Maharashtra

Product Incharge

Mr. Rohit

Address

Survey No. 15/1, Gujarwadi Road, Katraj Nagar, Pune, Maharashtra, 411046, India

scrubber system in Pune

Report incorrect details