Prince Engine Valves

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless steel alloys |

| Stem dia | 4mm to 20mm |

| Head dia | 20mm to 250mm |

| Length | Up to 500mm |

| Heat treatment | Yes |

| Surface treatment | Chrome plated/Tufftrided |

| Hardening process | Induction hardening |

| Features | High durability, Corrosion resistant, Easy fitting, Dimensional accuracy, Fine finish, Long lasting, Heat resistant, Optimal performance |

Product Overview

Key Features

We are pleased to introduce ourselves as one of the trusted manufacturers, suppliers and exporters of Engine Valves. The offered valves are used these for optimum performance for longer period of time at extreme temperatures and rusty surrounding under high dynamic load. Offered valves are manufactured using optimum quality stainless steel and other alloys in order to meet the international quality standards. To ascertain the quality of the offered product, these Engine Valves are thoroughly checked on certain well defined parameters of quality testing such as durability.

Features:

- Easy fitting

- Dimensional accuracy

- Fine finish

- Corrosion resistant

Other info:

Engine Valves

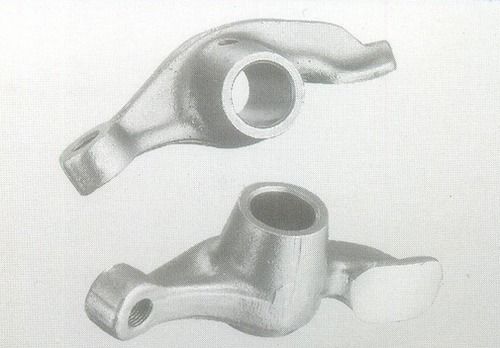

Prince Valves offer one of the widest range of Intake & Exhaust Engine Valves for Internal Combustion Engines. Globally accepted special steel of heat resistant alloy is used for Engine Valves to perform reliably over long period at elevated temperatures and corrosive environment under high dynamic load. Intake and Exhaust valves are offered from a wide range of materials such as: En52(SUH 1/SUH 11) for Inlet Valves and Austentic Steel 21-4N(SUH 35) or Bi-Metal for Exhaust valves with stem dia from 4mm to 20mm and Head dia from 20mm to 250mm and length up to 500mm. To ensure uniform mechanical properties of steel the material passes through proper Heat Treatment process. Valve stems are chrome plated or Tuff Trided/Nitrided to increase surface hardness of the stem & resistance to corrosion of lubrication. Valve seat portion and tip are hardened by special Induction hardening process to increase the corrosion and wear resistance.

Focusing briefly upon our production units, we have extensive research & development facility. The infrastructure fully equipped with special purpose sophisticated machines with the latest and advanced CNC technology. Cotter & grooves are made on a special purpose turning machine with in close tolerance & accuracy. Seat grinding is done on a special purpose machine to ensure consistent concentricity & cylendricity to match the International standard. An independent set up with dedicated team of technocrats and different in-house facilities for production & quality control attribute the maintenance of high quality standards laid down by ISO and meeting the demands of the OEM customers.

Technical Specifications

| JIS | BS | DIN | C | Si | Mn | P max | S max | Cr | Mo | Ni | N |

| SUH 1/ SUH 11 | ENS2 | 1.47 | 0.40 0.50 | 2.75 3.75 | 0.80 max | 4.04 | 4.04 | 7.50 9.50 |

| 0.50 max |

|

| SUH 3 |

| SUH11 | 0.45 0.55 | 1.00 2.00 | 0.60 max | 4.04 | 4.04 | 7.50 9.50 |

| 0.60 max |

|

|

|

| 1.47 | 0.35 0.45 | 1.80 2.50 | 0.60 max | 4.04 | 4.04 | 10.00 12.00 | 0.70 1.30 | 0.60 max |

|

|

| 21-2N | 1.49 | 0.50 0.60 | 1.00 max | 7.00 9.50 | 4.05 | 4.04 | 20.00 22.00 |

| 1.50 2.75 | 0.20 0.40 |

| SUH 35 | 21-4N | 1.49 | 0.48 0.58 | 0.25 max | 8.00 10.00 | 4.05 | 4.04 | 20.00 23.00 |

| 3.25 4.50 | 0.38 0.55 |

Company Details

Business Type

Manufacturer, Supplier

Employee Count

45

Establishment

1998

Working Days

Monday To Sunday

GST NO

07AAACP7822J1ZA

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 07AAACP7822J1ZA

Delhi, Delhi

Director

Mr. Joy

Members since

1 Years

Address

153, Dhirpur, Near Nirankari Colony, Delhi, Delhi, 110009, India

car engine valve in Delhi

Report incorrect details