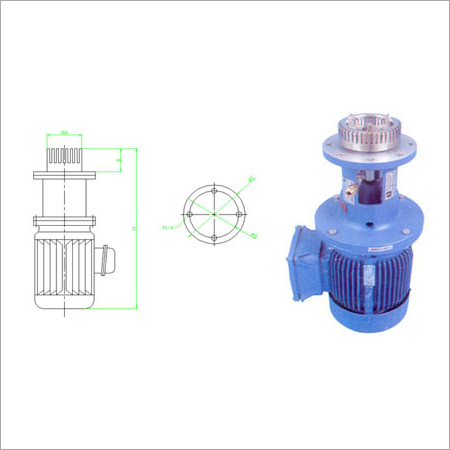

Emulsifier Mixer

Price:

Get Latest Price

In Stock

Product Specifications

| Main Domestic Market | All India |

Product Overview

Key Features

Remarks

The maximum working capacities in above table are based on water as the medium; - For high viscosity and high solid content materials, inline high shear dispersing emulsifiers are recommended to work together; - For special working conditions, such as high temperature and pressure, flammable, explosive or corrosive conditions, customers should provide detailed data; - FLUKO reserves the rights to change the specifications without announcement.

Working principle:

High shear dispersing and emulsifying is to efficiently, rapidly and uniformly distribute one or several phases into another continuous phase, while normally these phases are immiscible. The high tangential velocity produced by high speed rotor, and the strong kinetic energy produced by high frequency mechanical effect, can make materials subjected to intense mechanical and hydraulic shear, centrifugal squeezing, liquid layer friction, tearing, impacting, turbulence and other synthetic actions in narrow clearance between stator and rotor. Consequently, combined with mature processes and suitable additives, immiscible solid, liquid and gas phases can be dispersed and emulsified instantly. High frequency circulations will finally result in high quality and constant end products.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

200

Establishment

1999

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Shanghai, Shanghai

Marketing Director

Mr John Zhang

Address

#21-22 No.300, Shunda Road, Jiading District, Shanghai, Shanghai, 201802, China

high shear emulsifier in Shanghai

Report incorrect details

![Emulsifier-Calcium Stearoyl Lactylate [Csl]](https://tiimg.tistatic.com/fp/2/511/emulsifier-calcium-stearoyl-lactylate-csl--347.jpg)