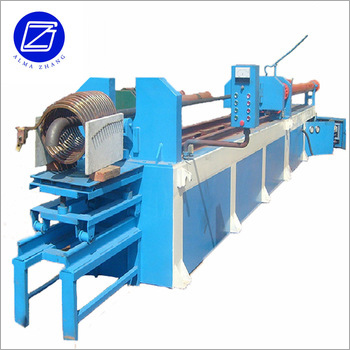

Elbow Making Machine With Induction Heating System

Price:

Get Latest Price

In Stock

Product Specifications

| Power | 30KW-100KW |

| Pipe Diameter | 50-300mm |

| Bending Radius | 1D-3D |

| Wall Thickness | 2-10mm |

| Material | Steel Pipes |

| Control System | PLC |

| Usage | Making 45°, 90°, and 180° pipe elbows |

| Features | Induction Heating, Efficient Bending, Uniform Wall, High Efficiency, Small Radius, Cost Effective |

| Product Type | Elbow Making Machine with Induction Heating System |

| Payment Terms | Telegraphic Transfer (T/T), Western Union, Paypal |

| Delivery Time | 2 Week |

| Main Domestic Market | All India |

Product Overview

Key Features

The process of intermediate frequency pipe bending is to put an induction ring on the part to be bent of the steel pipe, hold the pipe head with a mechanical swing arm, and heat the steel pipe with an intermediate frequency current in the induction ring. It is propelled by mechanical thrust and bent, and the bent steel pipe part is quickly cooled with a coolant, so that the bent pipe is continuously bent while heating, pushing, bending and cooling.

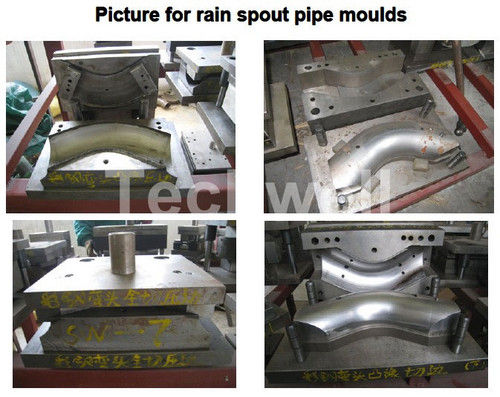

1) This process can avoid the unevenness of the wall thickness of the curved pipe caused by the thinning of the convex edge of the pipe wall and the thickening of the concave edge of the pipe wall during the traditional pipe bending process.

2) This process can be used to produce small-radius (Ra D) and thin-wall (t / Da 0.015) 180 elbows with uniform wall thickness, which cannot be achieved by other pipe bending processes.

3) If the design of various process parameters is reasonable, this process can ensure that the wall thickness of each part during the bending process is always the same, that is, it is always equal to the thickness of the straight tube wall before deformation.

4) This process can be used on the same horn mandrel to push the bends of 45 A , 90 A , 180 A and other bends with the same caliber at one time, with high production efficiency.

Company Details

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company, Wholesaler, Producer

Employee Count

50

Establishment

2011

Working Days

Monday To Sunday

Payment Mode

Letter of Credit at Sight (Sight L/C)

Certification

ISO 9001:2008

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Cangzhou, Hebei

Mrs Lemon

Address

905 of One World Business Center, Cangzhou, Hebei, 061000, China

elbow making machine in Cangzhou

Report incorrect details