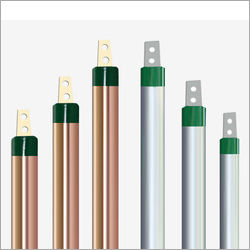

Earthing Electrode System By Multi Pressings

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Galvanized steel |

| Dimensions | Variable |

| Weight | Variable |

| Surface area | Large |

| Moisture booster | Yes |

| Installation method | Auguring |

| Galvanization | 100-300 microns |

| Features | Low resistance, Long lasting, Easy installation, No maintenance, Safe earthing, Cost effective, High performance, Moisture retention |

Product Overview

Key Features

Backed by an advanced infrastructure unit, we work extremely hard to manufacture and supply a prominent Earthing electrode System. Owing to its noise free operation, low power consumption and high performance level, the product is highly appreciated by the customers. The product is designed in such a way that it can easily meet the demands and requirements of our valuable clients. Our offered range of Earthing electrode System can reach the door-steps of our customers in committed time-frame.

Application Areas:

Steel sector

Telecommunication & space

Power generation sector

Railways

Earthing electrode System

After invention of the electricity people started using more and more sophisticated equipments such as micro processor based units. But no one thought of upgrading the Earthing Systems which is still in its conventional way.

Due to this nowadays people are facing various problems such as Breakdown failure, Data Corruption, Accidents amounting huge losses.

To avoid all these disadvantages we have introduced a best electrical earthing, sound in terminology with the current art of modern and advanced technology and product to declare that the object, target is only meant for electrical safety to man and machinery. A Product which is first of its kind in Asian Market. It is the Safe Earthing Electrode.

The main criteria of any earthing, will be flourished only depend upon the moisture content which has also been taken care by a marvelous compound called MOISTURE BOOSTER which will be used at the time of installation & such booster will have the character of retaining the moisture contents for very longer period. By the simple method of auguring of 8 to 10" dia, this MULTI MEES earth electrodes can be installed very easily (Installation method will be pasted in each electrodes) which will reflect immediately good results and no further maintenance is required. In short, it is totally and earthing solution for all your applications.

| Existing Method Of Earthing | MULTI MEES Earthing Electrodes |

| GI Pipe with funnel and holes | Duel pipe with flat Technology |

| Additional attachement of copper strip | Heavy type of terminal strip |

| Inadequate of Galvanization | Good amount of galvanization up to 100-300 microns |

| Require compulsory manitenance. | Intial watering & No Maintenance, No need to change/ replace |

| More Fluctuation in ohmic Value | No fluctuation of current & less Ohmicvalue |

| Use of charcoal & Salt | No charcoal & No Salt, filling with special compound |

| More space required for Installation (3' x 3' ) (4' x 4') | Less space for installation, required maximum 150mm - 200 mm dia bore. |

| Dissipation of fault / static current flow is less due to surface area corrosion | Fast dissipation of anyfault / static current due to more surface area, maintaining the moisture contents and no coroosion |

Infrastructure

Our-state-of-the-art infrastructure is backed with technologically advanced tools and machineries that help in the quality as well as quantity production of the Earthing Electrodes. Our robust infrastructural base i.e. manufacturing unit, warehouse, quality control lab and R & D unit have also provided invincible support in the fast and steady growth of the company.

Quality Assurance

Being a quality centric enterprise, various stringent quality tests are conducted under the supervision of the appointed quality control personnel. For further assurance, the products are tested at various levels. The products are also passed through the tests conducted by various independent testing laboratories.

Research & Development

The Team responsible for the Research & Development of the Products is putting consistent efforts so as to acquire satisfaction level of the clients. The regular feedbacks from the customers have also assisted in bringing innovations as per the demands of the market.

We have a huge clientele network that is spread in every nook and corner of the world. Customers are facilitated with the availability of products and services that have raised the bars of satisfactions. Moreover, working on the ideal and legal principles, our company has set a benchmark of quality and performance in a very short span. Last but not the least; we have made various meticulous efforts to provide transparent deals and become the foremost choice of our patrons.

MEES DIAMOND QUALITYBack Fill Compound

mees comes with an Ideal backfill compound which has all qualities to enhance the ground material. It is a ground enhancing to material. It is the good hydrodynamic and rich conductive compound. It is easily compacted and when water is added, it absorbs it fifteen times to dry volume. It consistently holds adheres to any surface it touches. These capabilities resolve the issue of compatibility of soil contact that are crucial to an earthing system. There is no need to recharge the pit in normal soils. Backfill compound is not soluble in water, It retains its moisture property upto the life the electrode which is more than 25 years in case of soil friendly materials.

It maintains moisture with in the sphere of influence of electrode, resulting in lower earth resistance which could not otherwise be obtained from the conventional earthing system, back fill enhance surrounding soil conductivity there by making it more effective for high fault , noise, ripples and hormonics, natural to earth imbalance and lightning current dissipation.

mees Suer Quality compound :Its contains natural elements which are highly conductive as well as anti corrosive. It does not disintegrate when the outer electrode corrodes.

- Less Time

- Less Space and manpower for installation.

- Negligible maintenance long and reliable average life of 15 to 20+ years. Cost saving on maintenance and no material replacement during its life period smooth dissipation of fault, lightning and short circuit current, low electrical resistance less corrosion.

Application

- Transmission & Distribution system.

- Substation and power generating stations.

- Tele communication Tower and microwave antennas.

- Transfer natural earthing, equipment body earthing, Sensitive electronic machines lightning.

- Arrestor earthing, Data processing center refineries and manufacturing facilities, food processing & water treatment plants, Industries Residences.

| As per IS 30431987 Requirements we are using SIP i.e. Strip in Pipe Technology. | |

| 1] Anti Corrosive 2] Highly Conductive 3] Hygroscopic.

| |

| Benefits: WE COMMIT WHAT WE DO | |

Company Details

Focusing on a customer-centric approach, MULTI PRESSINGS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Cables/Cable Accessories & Conductors in bulk from MULTI PRESSINGS at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

50

Establishment

1989

GST NO

29ABDPK9298C1ZA

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 29ABDPK9298C1ZA

Bengaluru, Karnataka

Accepts only Domestic inquiries

Seniour Manager (marketing)

Mr. Mahaveer Kanunga

Address

P.B. No. 27075, No. 54/C, Newly Formed Road, 4th Cross, Lalbagh Road, K.S. Garden, Bengaluru, Karnataka, 560027, India

chemical earthing electrodes in Bengaluru

Report incorrect details