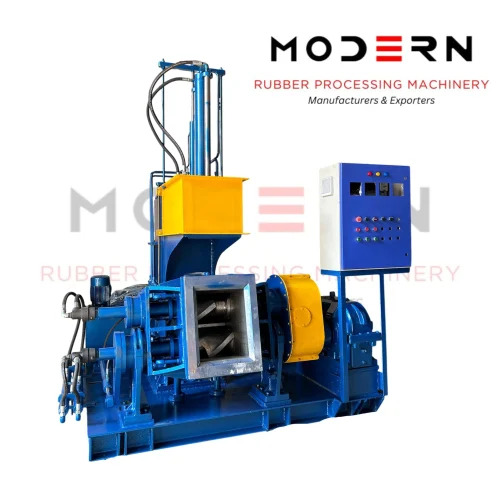

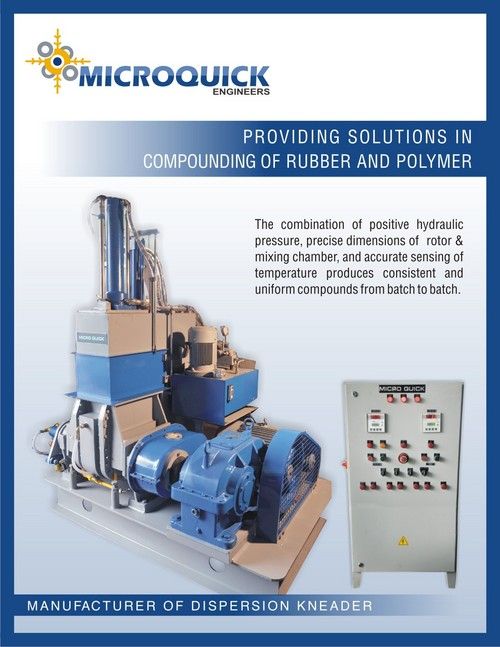

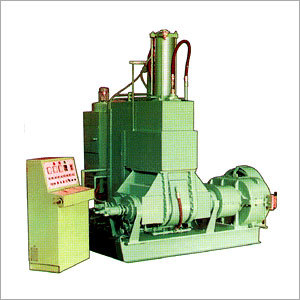

Dispersion Kneader Machine - High Efficiency Design, 50-100% Increased Production Capacity, Robust Rotor Configuration For Optimal Mixing And Dispersion

Price:

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Power | 50-100 kW |

| Capacity | 50-200 kg |

| Rotor Speed | 10-50 rpm |

| Material | Steel |

| Dimensions | 2x3x2 m |

| Weight | 2000-5000 kg |

| Usage | Rubber, plastic compounding |

| Compliance | CE |

| Features | Uniform Dispersion, Consistent Quality, High Production, Low Costs, Easy Operation |

| Payment Terms | Cash Advance (CA), Cash in Advance (CID) |

| Delivery Time | Within 10-15 Days |

| Sample Policy | Contact us for information regarding our sample policy |

Product Overview

Key Features

Enhanced Quality

The differential rotation of rotors, Helical, Wide width of rotor wings and clearance of rotors gives excellent Pressing / Shear / Tear / Folding / Stretching / Smear of ingredients of compound. This leads to the best kneading effect and promotes the uniform dispersion of fillers. The cooling circuit is designed inside wing of rotors & all around mixing chamber. The result is quality compounding at less temperature even at high rate of production.

Consistent Quality

The time of mastication and filler compounding can be monitored for each batch preparations with timer of Control Panel. This leads to consistent quality of compounding for each batch. Very less fly loss of filler during mixing than that of mixing mill.

Production up to two times higher

With well proven kneading technology, it is now possible to increase in production of 50 to 100 % than that of mixing mill.

The batch preparation time could be between 8 to 15 minutes. The compounding takes place normally, with mastication time - 2 to 4 minutes and filler compounding time of - 4 to 8 minutes.

Lower Overall Costs

The kneader can be operated with semi skilled person / learned helper. The person can be trained with in one-two hours for batch preparations.

Company Details

Focusing on a customer-centric approach, MICRO TECH ENGINEERS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Rubber Machinery in bulk from MICRO TECH ENGINEERS at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Related Products

More Product From This seller

Seller Details

Gandhinagar, Gujarat

Proprietor

Mr Nilesh Parikh

Address

A55, Shivshakti Estate Phase 1, Near Kiran Industries,Vatva Gidc, Gandhinagar, Gujarat, 382445, India

dispersion kneader in Gandhinagar

Report incorrect details