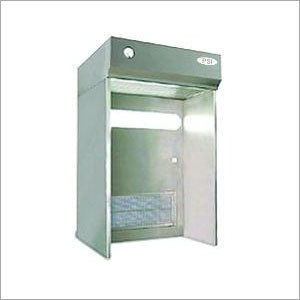

Dispensing Booth - Ss304 & Ms Powder Coated, Class 100 Cleanliness With 3-stage Filtration | Who-gmp Compliant, Heavy Duty Low Noise Blower Assembly

Price:

Get Latest Price

In Stock

Product Specifications

| Material | SS304/MS |

| Cleanliness Class | ISO 5 |

| Particle Retention | 0.3 micron |

| Noise Level | 65dB |

| Air Velocity | 90 FPM |

| Power Supply | 230V |

| Filtration | HEPA |

| Features | Dust control, Operator safety, Three-stage filtration, GMP compliant, Product protection, Efficient airflow, Easy to use |

Product Overview

Key Features

Dispensing / Sampling booths

Dispensing / Sampling booths are used for filling, refilling, weighing & sampling of Raw material & Components

Booths are designed to give mixed air flow stream for product, operator and environmental protection and used to control the hazardous emissions of dust powder during powder dispensing / sampling process. 0.3 micron downward air stream deflects air-borne dust away from the operator breathing zone which is caused in handling operation. Dust particle available is being filtered at three levels of filtration prior to being circulated back to the booths air stream.

Specifications

| Description | Specifications |

| Type | Front Open |

| Direction of flow | Vertical |

| Material of Construction | SS304 / MS Powder Coated |

| Cleanliness | Class 100 (US FED STD 209E) / ISO 5 (ISO 14644) |

| Particle Retention | 0.3 micron & Above |

| Noise Level | 65dB on On Scale 'A' 5 |

| Velocity | 90 FPM 20% |

| Illumination | Flourescent tubes diffusers |

| Pressure Differential | 0-25 mm inclined Manometers / Magnehelic Guage |

| Power Supply | 230V Single Phase, 50 Hz |

| Pre-Filters | 10 - 15 micron rating, 3-Layers of HDPE mesh, 6mm Pressure Drop |

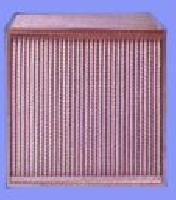

| Intermediate Filters | 3 micron & above, two layers of HDPE woven mesh and one layer of Non-woven polyester Bondex Media, 9 mm Pressure Drop, Efficiency 97% |

| Supply HEPA Filters | 99.97% efficiency @ 0.3 micron ratting |

| Exhaust HEPA Filters | 99.97% efficiency @ 0.3 micron ratting |

| Blower Assembly | Statically & Dynamically balanced DIDW type blower system |

Special Features

- Designed in accordance with WHO-GMP

- 3-Stage Filteration like Prefilter , Fine Filter , HEPA filter

- Heavy duty Low noise motor blower assembly

- Suitable to accommodate to floor & table balances

Company Details

Focusing on a customer-centric approach, CADILLAC ENGINEERING WORKS has a pan-India presence and caters to a huge consumer base throughout the country. Get Clean Room Equipment from CADILLAC ENGINEERING WORKS at Trade India quality-assured services.

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

18

Establishment

1980

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Kolkata, West Bengal

Managing Partner

Mr. P. Gupta

Address

69 B, Santoshpur Avenue, Santoshpur, Jadavpur, Kolkata, West Bengal, 700075, India

dispensing booth in Kolkata

Report incorrect details