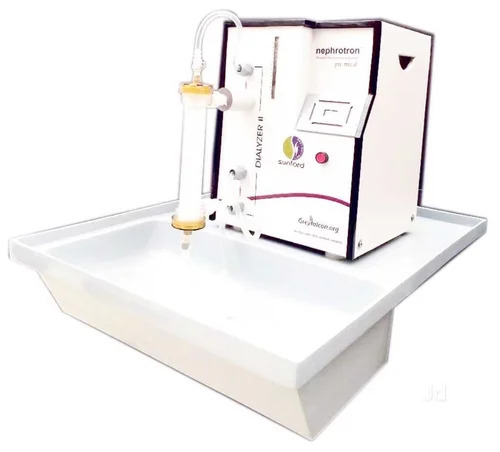

Dialyser Reprocessing System

Price:

Get Latest Price

In Stock

Product Specifications

| Dimensions | 31x25x65 cm |

| Weight | 35 Kg |

| Input Voltage | 230V |

| Power | 500W |

| Leakage Current | <0.1 mA |

| Ambient Temperature | 5-45 °C |

| Relative Humidity | 10-80% |

| Features | Automated cleaning, Excellent functionality, Accurate & safe, Effective processing, Programmable sequence, User-selectable timing, LCD display, Printer output |

Product Overview

Key Features

With an experience of 16 years, we are engaged in offering excellent quality Dialyser Reprocessing System. It is extensively used in dispensaries, hospitals and clinics for reprocessing the used dizlyzer for its re-use on the kidney dialysis patient. This system is made available in different specifications to fulfill the demands of our clients. Our dexterous professionals manufacture our offered system in accordance with latest market standards by making use of quality approved raw material. Our esteemed clients can avail this Dialyser Reprocessing System from us at nominal prices.

Features:

-

Automates the dialyzer cleaning

-

Excellent functionality

-

Accuracy and Safety Operation

-

Effective Processing Time

Dialyser Cleansing System - DCS - FS

Fully automated dialyser reprocessing system with programmable sequence and timing option allows chemical / disinfectant of user's choice.

Dialyser Test Details

- Leak Test: Blood Leak test and System Integrity test

- Volume Test: Online dynamic volume test. Automatically detects fill of fluid and volume measured.

User Selectable timing of different process. Each process can be configured by the user.

User Access and Reports

4 lines x 16 Character LCD

Alarm and Safety Features

- System Integrity Test

- Bundle Volume Test fail

- Pressure Test fail

- Visual Indication for each sequence

- Printer output with time stamp

- Incomplete machine disinfection alarm

- Dimension: 31x25x65 cm

- Weight: 35 Kg Table Top

- Input Voltage: 230V + /- 5%, 50 Hz

- Power: 500W

- Leakage Current: <0.1 mA, 220V

- Ambient Temperature: 5-45 Degree Centigrade

- Relative Humidity: 10-80%

- Purity: R.O. Water in accordance with AAAMI/ ANSI standard

- Inlet Pressure: 24 psi - 40 psi

- Inlet Temperature: 10-40 degree Centigrade

- Inlet Flow: 2.5 I/min (Minimum)

- Drainage: Should be at least 1" (2.5 cm) below the machine base

EMI/ EMC certification from Sameer (Govt. of India) that the product meets the IEC 60601-1-2 safety standard.

Company Details

Business Type

Exporter, Importer, Manufacturer, Supplier, Trading Company

Employee Count

50

Establishment

1975

Working Days

Monday To Sunday

GST NO

09AAEPA7509G1ZX

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 09AAEPA7509G1ZX

Greater Noida, Uttar Pradesh

Managing Director

Mr. Pulkit

Members since

15 Years

Address

BNo I 82 , SITE C, SURAJPUR INDL AREA, GR NOIDA, Greater Noida, Uttar Pradesh, 201308, India

dialyzer reprocessing machine in Greater Noida

Report incorrect details