Deodorising Apparatus - Stainless Steel 60l Vessel | Computer Controlled Heating, Multi-stage Vacuum System, Advanced Scada & Pid Control

Price: 100 INR / Unit

Get Latest Price

Minimum Order Quantity :

1 Unit

Brand Name :

Teknik

In Stock

Product Specifications

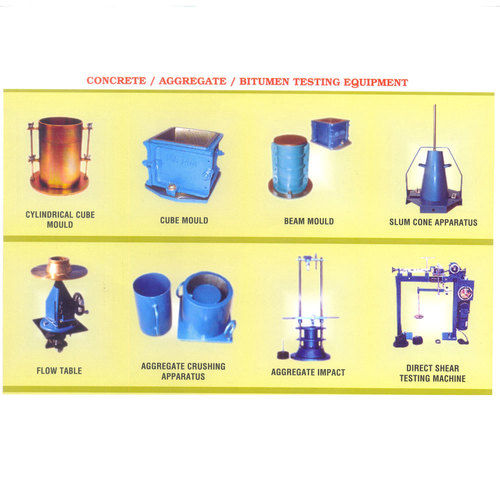

| Usage | Civil Engineering Lab Equipments |

| Application | Civil Engineering Lab Equipments |

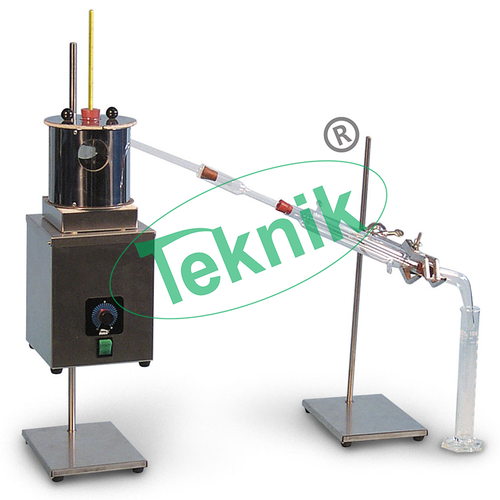

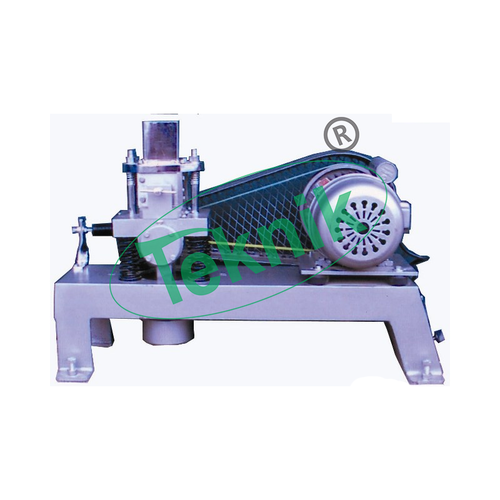

| Product Type | Deodorising Apparatus |

| Supply Ability | 100 Per Week |

| Delivery Time | 1 Week |

| Sample Available | Yes |

| Sample Policy | Sample costs shipping and taxes has to be paid by the buyer |

| Packaging Details | carton box, export quality also available |

| Main Export Market(s) | Africa, Middle East, Asia |

| Main Domestic Market | All India |

| Certifications | ISO 9001, 14001 ,CE |

Product Overview

Key Features

Unit suitable for teaching/training and research into the principles of steam stripping of fatty acids from edible oils. This is a floor-standing batch processing vessel.

Stainless steel and anodized aluminium support structure.

Diagram in the front panel with similar distribution to the elements in the real unit.

Elements in contact with the process fluid are constructed in stainless steel.

Deodoriser vessel:

60 litres overall volume.

25 litres working volume.

Product maximum temperature: 250 C.

Electrical heating element (electric resistance), computer controlled, to heat the oil to temperatures of up to 250 C. (3KW approx).

Cooling water coil for reducing the oil temperature on completion of the process.

Steam distribution tube, which allows the steam/oil mixing required.

Window for the process visualization.

Multi-stage vacuum system, incorporating:

Steam ejector.

Condenser.

Vacuum pump, computer controlled.

Discharge pump.

Polishing filter to remove any remaining particles in the finished oil.

Pressure sensors.

Temperature sensors.

Level sensor.

Sample collecting.

Modes of operation:

Deodorising:

The oil is heated under vacuum using direct steam to provide the agitation for good heat transfer. When the desired pressure and temperature are achieved, the direct steam injection is adjusted to impart a high degree of turbulence to the oil, ensuring good physical contact of the steam with the oil. The impurities are carried over in the steam and condensed in the vacuum condenser, the resulting condensate blending with the vacuum pump sealant to be discharged to drain.

Polishing:

After deodorisation, the oil refining process is complete. The oil must therefore be free of any contaminants. For this, it is pumped through a polishing filter which removes those particles, giving a bright oil as product.

The complete unit includes as well:

Advanced Real Time SCADA and PID Control.

Open Control + Multicontrol + Real Time Control.

Own Control Software based on Labview.

National Instruments Data Acquisition board (250 KS/s (kilo samples per second)).

Calibration exercises included.

Students multipost (an entire class) by using a projector.

Ready for doing applied research, real industrial simulation, training courses possibilities, etc.

Unit is totally safe (Mechanical, Electronic/Electrical and Software safety devices included).

Results calculation and analysis software (CAL).

Several future expansions, as ESN. Scada-Net System (many students working simultaneously), and more.

Designed and manufactured under several quality standards.

Company Details

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

25

Establishment

1973

Working Days

Monday To Saturday

GST NO

06ACMPJ7244B1ZS

Certification

ISO 9001 : 2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 06ACMPJ7244B1ZS

Ambala Cantt, Haryana

Ceo

Mr Vikas Jain

Members since

13 Years

Address

Plot No. 73, Vikaspuri, Industrial Area, Ambala Cantt, Haryana, 133001, India

civil engineering lab equipment in Ambala Cantt

Report incorrect details