Compressors & Allied Equipment

(4709 products)Product Showcase

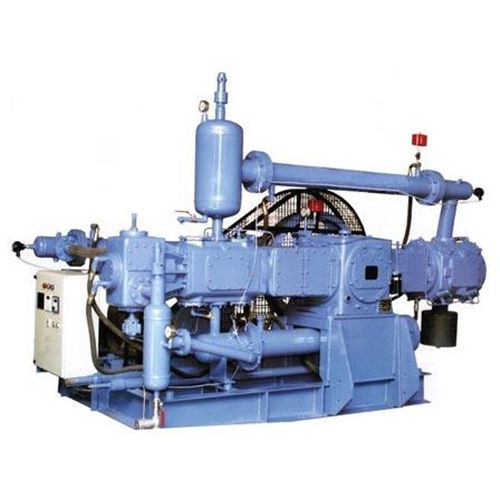

Blue Pet Blowing Air Compressor

By:

Priya Enterprises

Compressors Spares Parts - Precision Engineered, Multiple Sizes & Specifications | Reliable Design, Dimensional Accuracy, Easy Installation

1500-45750 INR

By:

Prs Compressors Pvt. Ltd.

Compressors Spares Parts - Precision Engineered, Multiple Sizes & Specifications | Reliable Design, Dimensional Accuracy, Easy Installation

Price Trend: 1500-45750 INR/Unit

MOQ1 , Unit/Units

UsageCompressors

Product TypeSpares Parts

Prs Compressors Pvt. Ltd.

Tirupur

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller6 Years

Double Inlet Impeller - Color: Silver

Price: 600.00 INR/Piece

MOQ10 Piece/Pieces

UsageIndustrial

Frequency50 Hertz (HZ)

Control SystemManual

Colorsilver

MaterialAluminium

StructureOther, Double

Re Blowers India Private Limited

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller15 Years

Cement Silo Compressor - Application: Industrial

Price Trend: 110000.00 - 150000.00 INR/Unit

MOQ1 Unit/Units

MaterialOther

Type Of CompressorOther, Cement Silo Compressor

FinishOther

ConfigurationPortable

Power SourceAc Power

Product TypeCement Silo Compressor

Air Vac Equipments

Ahmedabad

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller7 Years

5Hp Oil Free Compressor - Lubrication Type: Oil-Less

Price: 70000 INR/Unit

MOQ1 Unit/Units

ConditionNew

Materialmetal, Iron, Aluminium

Lubrication TypeOil-less

Working Presssure8

Warrantyone year

Airo-tech Enterprises

Vasai

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller12 Years

BAC Reciprocating Air Compressor

Payment TermsOthers, Cash Against Delivery (CAD), Cash Advance (CA)

Main Domestic MarketAll India

Berlin Machineries Private Limited

Pune

Trusted Seller

Trusted Seller Premium Seller

Premium Seller5 Years

Stainless Steel Rotary Air Compressor

Price: 60000 INR/Piece

MOQ1 Piece/Pieces

ColorBlue

Product TypeRotary Air Compressor

UsageIndustrial

Type Of CompressorTurbo

MaterialStainless Steel

ConfigurationStationary

Leelam Industries

Ahmedabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller17 Years

50 Hp Screw Air Compressor - Color: Red

Price: 300000 INR/Unit

MOQ1 Unit/Units

Frequency50-60 Hertz (HZ)

UsageBlasting & painting

Cooling MethodAir Cooling

ColorRed

Type Of CompressorScrew

ConfigurationStationary

Shree Enterprises

Navi Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller2 Years

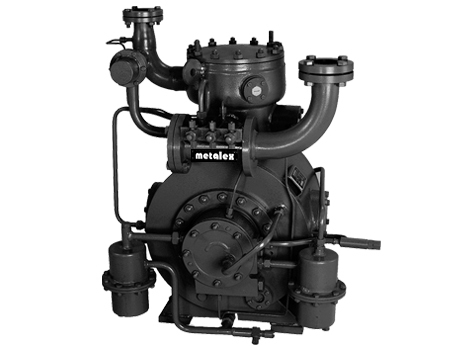

Ammonia Single Cylinder Compressor - Lubrication Type: Lubricated

Price Trend: 300000.00 - 1200000.00 INR/, Set

MOQ1 , Set/Sets

UsageCold Storages , Chilling Plants , Dairies , Ice Plants.

Type Of CompressorPiston

Allied EquipmentOther

ConfigurationStationary

Power SourceOther

SilentNo

Metalex Cryogenics Ltd.

Pune

Trusted Seller

Trusted Seller Super Seller

Super Seller14 Years

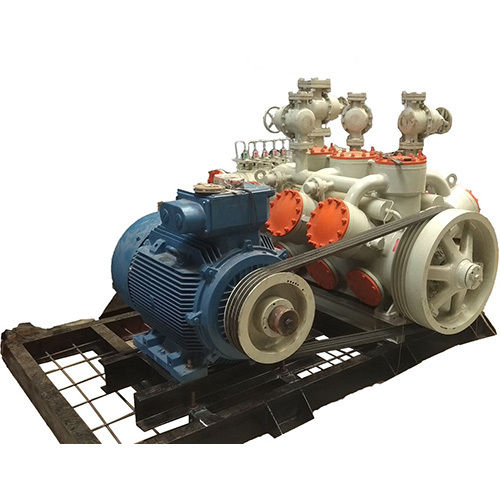

Industrial Air Compressor - Heavy-Duty Cast Iron | High Efficiency, Low Noise Operation, Versatile Applications

Price: 110000 INR/Unit

MOQ1 Unit/Units

Flow Rate900 LPM

Motor Power10 HP

Cooling MethodAir Cooled

Weight520 kg

Filtration GradeIndustrial Grade

Drive TypeOther, V-Belt

Air Vac Equipment

Ahmedabad

Trusted Seller

Trusted Seller Super Seller

Super Seller18 Years

Danfoss Condensing Units - Electric Driven, 220 Statampere | Reliable Performance, Robust Design, Heat Resistance

Price Trend: 30000 - 250000 INR/Number

MOQ1 Number

Voltage220 Statampere (sA)

Driven ModeElectric

Ishwar Climate Solutions Private Limited

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller10 Years

Air Pipe Lines - PPR/Aluminium, Customized Size, Blue Color | 6 Bar Flow Rate, Self-Priming, Low Pressure, Viton Seal, Silent Operation, 2-Year Warranty

Price: 200 INR/Meter

MOQ50 Meter/Meters

ColorBlue

Inlet/Outlet1/4

Flow Rate6 bar

LengthCustomized Meter (m)

TheoryOther

Product TypePipe Line

Bright Industries

Palghar

Trusted Seller

Trusted Seller Super Seller

Super Seller7 Years

15 Hp Screw Air Compressor - Color: Black

Price: 185000 INR/Piece

MOQ1 Piece/Pieces

Product Type15 HP Screw Air Compressor

Drive TypeElectric

Frequency50 Hertz (HZ)

SizeStandard

PhaseThree Phase

ColorBlack

Dadashree Industries

Ahmedabad

Trusted Seller

Trusted Seller Super Seller

Super Seller3 Years

Ah Series Air Oil Cooler - Lubrication Type: Lubricated

MOQ10 Unit/Units

Cooling MethodAir Cooling

UsageIndustrial

ConfigurationStationary

Power SourceAc Power

SilentNo

Lubrication TypeLubricated

Automation Controls & Equipments

Mumbai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller1 Years

Screw Air Compressor - Color: Customised

Price: 500000 INR/Unit

MOQ1 Unit/Units

UsageIndustrial

ColorCustomised

Product TypeSCREW AIR COMPRESSOR

Type Of CompressorRotary

ConfigurationStationary

Power SourceAc Power

Industrial Ammonia Compressor - Lubrication Type: Lubricated

Price: 125000 INR/Unit

MOQ10 Unit/Units

Type Of CompressorScrew

ConfigurationStationary

Power SourceAc Power

SilentNo

Lubrication TypeLubricated

Vishwakarma Engineering

Vadodara

Trusted Seller

Trusted Seller Super Seller

Super Seller3 Years

Air Regulator - Silver, 1/4" Inlet/Outlet, N.W. 225.0 g | Standard Size, Industrial Use

Price: 181.19 USD ($)/Set

MOQ20 Set/Sets

Phase1

UsageIndustrial

SizeStandard

Product TypeAir Regulator

ColorSilver

Jo Long Machine Industrial Co., Ltd.

Dali

Trusted Seller

Trusted Seller Premium Seller

Premium Seller7 Years

Twin Lobe Air Compressor - Premium Quality Raw Materials , Optimized for Oil Free Air Delivery and Enhanced Efficiency

Product DescriptionWe are inserted amongst the impressive manufacturer, exporter, trader, distributor and supplier a widespread selection of Twin Lobe Air Compressor in Pune, Maharashtra, India. We manufacture this compressor using premium quality raw materials and technological advancements under the guidance of expe

Kpt Industries Limited

Pune

Trusted Seller

Trusted Seller Premium Seller

Premium Seller13 Years

Acetylene Compressor - High Quality Material Construction | Enhanced Efficiency for Long-Term Performance

Product DescriptionEnriched with vast industrial experience, we are involved in offering wide range of Acetylene Compressor. The use of high quality examined material is done in production this range which make them really efficient in performance for a longer period of time.\015\012

Kvk Corporation

Mumbai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller11 Years

Steam Water Mixing Battery - High-Efficiency Design , Versatile Integration Capabilities and User-Friendly Operation

Price: 60000 INR/Unit

MOQ1 Unit/Units

Handles1

Weld Arc Engineers

Vadodara

Trusted Seller

Trusted Seller Super Seller

Super Seller4 Years

DN20~DN200 Aluminum Pipe for Solar PV Project

MOQ1 Piece/Pieces

Product TypeAluminum Pipe

Shanghai Hai Hong Shun Industrial Co., Ltd..

Kunshan

Trusted Seller

Trusted Seller Premium Seller

Premium Seller3 Years

Grey Single And Two Stage Industrial Reciprocating Compressor

MOQ1

Product TypeAir Compressor

UsageIndustrial

ColorGrey, Black

Type Of CompressorReciprocating

ConfigurationStationary

Power SourceAc Power

Elgi Equipments Limited

Coimbatore

Trusted Seller

Trusted Seller Premium Seller

Premium Seller4 Years

Black Zr380 Emerson Copeland Compressor

Price: 95,000 INR/Piece

MOQ5 Piece/Pieces

ColorBlack

UsageIndustrial

Type Of CompressorOther

ConfigurationPortable

Lubrication TypeLubricated

WarrantyYes

A.K Trading

Delhi

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Dc Fan Motor Series Air Oil Cooler Usage: Industrial

Price: 4065 INR/Piece

MOQ1 Piece/Pieces

Weight2 Kilograms (kg)

UsageIndustrial

Product TypeDc Fan Motor Series Air Oil Cooler

Allied EquipmentMotor

Voltage220-240 Volt (v)

Mining Air Compressors - Color: Green

Price: 15000 INR/Unit

MOQ1 Unit/Units

UsageFor Commercial Use

ColorGreen

Product TypeAir Compressors

Type Of CompressorPiston

Allied EquipmentCompressor Head

ConfigurationPortable

Integrated Engineers & Contractors

Sonipat

Trusted Seller

Trusted Seller Super Seller

Super Seller22 Years

Diesel Engine Driven Air Compressor - Color: All

Price: 400000 INR/Piece

MOQ1 Piece/Pieces

Usageindustrial

Product TypeDiesel Engine Driven Air Compressor

Sizecustomize

Colorall

ConfigurationPortable

Power SourceDc Power

Sri Balaji Workshop Pvt Ltd

Coimbatore

Trusted Seller

Trusted Seller1 Years

50 Hp Lubricated Fixed Speed Screw Air Compressor - Color: Grey

Price: 440500.00 INR/Unit

MOQ1 Unit/Units

Product TypeScrew Air Compressor

Cooling MethodAir Cooled

Noise Level72+-2 db

UsageIndustrial

Control SystemPLC

Weight700.00 Kilograms (kg)

Kk Techno Solutions

Noida

Trusted Seller

Trusted Seller Premium Seller

Premium Seller8 Years

Air Receiver - Durable Steel | Compact Design, High Reliability, Long-lasting Performance

Product DescriptionWe are a highly reliable company of the industry, engaged in Manufacturing, Supplying and Exporting distinct quality Air Receiver. The products provided by us are widely appreciated among the customers for their various features such as compact design, reliability and durability

Summits Hygronics Private Limited

Coimbatore

Trusted Seller

Trusted Seller Super Seller

Super Seller3 Years

Packing Seal Assembly - Portable, Manual Driven, Lubricated Design | Silent Operation, Various Sizes Available, Warranty Included

Price: 3,145 INR/Piece

MOQ10 Piece/Pieces

UsageIndustrial

SizeDifferent available

ConfigurationPortable

SilentYes

Lubrication TypeLubricated

Driven ModeManual

Mahad Infrastructure Private Limited

Mumbai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Latest From Compressors & Allied Equipment

Automobile Division

By:

Sea-bird Refrigeration Pvt. Ltd.

Conditioning Compressor Spare Part

By:

Air Freeze Enterprises

Single Stage Two Cylinder Compressors

By:

Macshe Equipment Pvt. Ltd.

Large Series Screw Compressors

By:

Gea Grasso Gmbh

Compressors Allied Equipment

By:

Kompressor Systems Inc.

Compressed Air Receiver

By:

Khushal Pneumatics

Compressors & Allied Equipment

By:

Hallmark Compressor Private Limited

Compressors & Allied Equipment

By:

Blovac Systems

Compressor Piston Assembly

By:

Ramco India

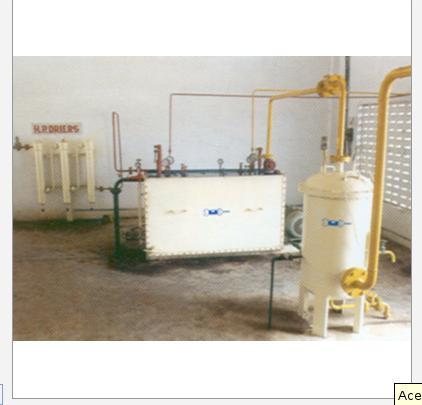

Air Compressor / Dryer & After Coolers

By:

Dynamic Enterprises Inc.

Popular Compressors & Allied Equipment

Compressors & Allied Equipment - Overview

In 1937, Allied Equipment established a new distribution center at 545 East 4th Street. The company distributed a wide variety of products, including snow plows, LED traffic signals, and farm machinery. A gas compressor is a machine that reduces the gas's volume in order to increase its pressure.

In addition to air, natural gas, oxygen, and nitrogen—all of which have significant industrial applications—are also compressed. Compressors can be categorized into three broad categories: positive displacement, centrifugal, and axial.

A high-speed impeller in a centrifugal compressor boosts the gas's kinetic energy, which is then converted to more pressure in a diffuser located at the compressor's divergent exit.

What type of equipment is an air compressor?

1. Rotary Screw compressor

Displacement compressors like rotary screws are among the most user-friendly, thanks to their built-in cooling systems that require little attention.

These machines are primarily used in industrial settings and are very huge. To provide power, rotary screw air compressors use two rotors spinning in opposite directions inside the machine. As the air builds up between the two rotors, the pressure inside the housing increases.

These air compressors have a horsepower range from 5 to 350 and feature an internal cooling system, making them suitable for 24/7 operation.

2. Reciprocating Air Compressors

Other common displacement compressors use a revolving compressor. They are commonplace in garages and domestic construction sites.

The reciprocating compressor, in contrast to the rotary screw compressor, is not intended for nonstop operation.

When it comes to moving parts, a reciprocating air compressor has more, and these are maintained with oil to provide a more efficient and quiet operation. In a reciprocating compressor, a piston moves within a cylinder, compressing and displacing air to increase pressure.

The pressure ranges that can be attained by different types of reciprocating compressors depend on whether or not they are single-stage or multi-stage designs.

3. Axial Compressors

Power is produced by dynamic Compressors & Allied Equipment, which work by drawing in air with rapidly spinning blades and then compressing it to increase pressure.

Then, the compressor will take that kinetic energy and convert it to static energy. When it comes to dynamic compressors, axial and centrifugal designs dominate the market.

Normal construction practices tend to avoid the use of axial air compressors. Instead, you can find them in the high-powered engines of ships and jets.

4. Centrifugal Compressors

Because of their high efficiency rate, axial compressors are well suited for aerospace applications needing high horsepower, but they are also significantly more expensive than other types of air compressors.

Air entering a centrifugal compressor is slowed and cooled by a diffuser to increase its potential energy. Since centrifugal compressors use a multi-phase compression process, they may generate a lot of power despite their compact size.

5. Oil Flooded Air Compressor

Compressors can also be categorized based on their lubrication, which can be either oil-flooded or oil-free. Compressors that are "oil flooded" have oil lubricating their moving parts. In particular, their compression chambers are sealed and lubricated with oil.

Oil-flooded designs are common in rotary screw and reciprocating compressors.

Oil-flooded compressors tend to last longer because of the regular lubricating they receive. But they can leak lubricant into the compressed air and ruin it.

6. Oil-Free Air Compressor

In contrast, oil-free air compressors don't use any kind of oil in the compression process. Instead, their moving parts are pre-lubricated with a long-lasting alternative lubricant that is integrated into the design. This means they can generate pollution-free air by removing all residues of potentially dangerous oil.

Generally speaking, centrifugal compressors don't require oil, and there are also oil-free rotary screw and reciprocating compressors.

These may cost more, but they're more efficient (meaning they use less energy) and quieter (meaning they don't disrupt your workday as much) than the alternatives. Because of these benefits, they are well-suited for building in high-traffic regions or environmentally conscious settings.

7. Scroll Air Compressor

According to international standards, scroll compressors create the cleanest air. Construction projects or businesses with stricter environmental requirements may benefit from using such equipment.

They are also adaptable, as they can function at a range of intensities. Scroll compressors are low-noise and low-maintenance, but they aren't the most powerful option available.

Although a different kind of compressor may be needed for heavy-duty tools and machinery, the passive uses are best suited to the more lightweight compressors.

Understanding Compressors : Types

i. Piston Compressor

Compressing gas in a cylinder (or cylinders) and releasing it through valving into high pressure receiving tanks is the job of a piston compressor, also known as a reciprocating compressor.

The tank and the compressor are frequently assembled into a single "packaged unit" on the same frame or skid.

Although delivering compressed air as an energy source is where piston compressors shine the brightest, pipeline operators also rely on piston compressors when transporting natural gas.

Both the desired pressure (in psi) and the desired flow rate play a role in determining which piston compressor to use (scfm).

ii. Diaphragm Compressor

It's an improved version of the reciprocating type, driven by a motor-mounted eccentric that vibrates a movable disc to increase and decrease the size of the compression chamber.

Similar to a diaphragm pump, the flexible disc separates the drive from the process fluid, preventing lubricant from mixing with any gas.

iii. Helical Screw Compressor

For applications that require constant use, such as construction or roadwork, a helical-screw compressor is an excellent choice among rotary compressor machines.

Geared based Compressors, meshing female and male draw in gas, compress it as the gas passes axially along the rotors' length, and then release the compressed gas through a port on the opposite end of the compressor casing. Because of the rotary screw compressors lower vibration, it operates more quietly than a reciprocating compressor.

iv. Sliding Vane Compressor

Sliding-vane compressors use a set of vanes mounted on a rotor to move down the curved wall of an eccentric chamber. As the vanes spin from the suction side to the discharge side of the eccentric cavity, they diminish the volume of space they are sweeping by, compressing the gas that is trapped within the space.

An oil film forms on the wall of the eccentric chamber, and the vanes slide along it, creating a seal. Although oil-free air from sliding-vane compressors is not possible, pulsation-free compressed air can be produced. Because of the low operating speeds and the use of bushings instead of bearings, these compressors are tolerant to environmental pollutants.

v. Scroll air Compressor

In a scroll air compressor, the volume of space between the fixed and orbiting spirals is reduced as the latter follow in the fixed spirals' footsteps. The gas is sucked in at the edges of the scrolls and released from its compressed state in the middle.

The compressor does not require any lubricating oil because the scrolls do not come into contact with one another.

Capacity for scroll compressors is limited due to the absence of oil used in other systems to remove the heat of compression.

vi. Centrifugal Compressor

Pump-like impellers spin rapidly in centrifugal compressors, increasing the kinetic energy of the gas and thus the pressure.

They are typically found in high-output applications such commercial refrigeration units (100 hp+) and large processing plants (20,000 hp+, delivering quantities of up to 200,000 cfm+).

To enhance the speed of gas, centrifugal compressors work by propelling it outward at high velocities via a rotating impeller, much like a centrifugal pump. The gas's velocity decreases and its pressure increases as it expands inside the casing's volute.

8. Axial Compressor

Axial compressors can produce the highest supplied air volumes, anywhere from 8,000 to 13 million cfm, making them ideal for use in large industrial machinery. Compressors of this type are used in jet engine systems to create volumes throughout an even larger spectrum.

Axial compressors, because of their low compression ratios, are typically more complex multi-stage designs than centrifugal compressors.

When compared to other forms of energy production, air compressors are far more secure and user-friendly. Construction workers naturally benefit greatly from this because of the increased dangers they face on the job. If you keep your air compressor well-lubricated, it has a significantly lower risk of overheating.

Air conditioners can be quite pricey to repair or replace due to the high cost of the compressor. It is more cost-effective to replace the entire AC unit than to repair individual parts. If the compressor is making grinding noises or is hard to start up ("hard starting"), you should get it fixed as soon as possible.

FAQs: Compressors & Allied Equipment

Q. What is compressor equipment?

Ans. A mechanical device, compressor equipment reduces the volume of a gaseous substance while simultaneously increasing its pressure. One variety of gas compressors is the air compressor.

Q. Which oil is used in compressor?

Ans. Synthetic oil and Mineral oil are two types of oil used for operating compressor device.

Q. What SAE is compressor oil?

SAE is non detergent air compressor oil. This is the best option for an air compressor that runs on oil. A shorter compressor lifespan is a direct result of the use of detergent oils, which can lead to carbon buildup.

Q. What are the parts of compressor?

Ans. Compression Cylinder, Air Filters, Rotors, Rollers, Bearings, Discharge Valve, Suction Valve, Oil Filters, Gaskets & Seals, Separators, and Storage Tanks are some parts of Compressor.

Manufacturers & Suppliers of Compressors & Allied Equipment

Company Name | Member Since |

|---|---|

Integrated Engineers & Contractors Sonipat, India | 22 Years |

Air Vac Equipment Ahmedabad, India | 18 Years |

Leelam Industries Ahmedabad, India | 17 Years |

Re Blowers India Private Limited Mumbai, India | 15 Years |

Metalex Cryogenics Ltd. Pune, India | 14 Years |

Kpt Industries Limited Pune, India | 13 Years |

Airo-Tech Enterprises Vasai, India | 12 Years |

Kvk Corporation Mumbai, India | 11 Years |

Ishwar Climate Solutions Private Limited Mumbai, India | 10 Years |

Kk Techno Solutions Noida, India | 8 Years |

Popular Products