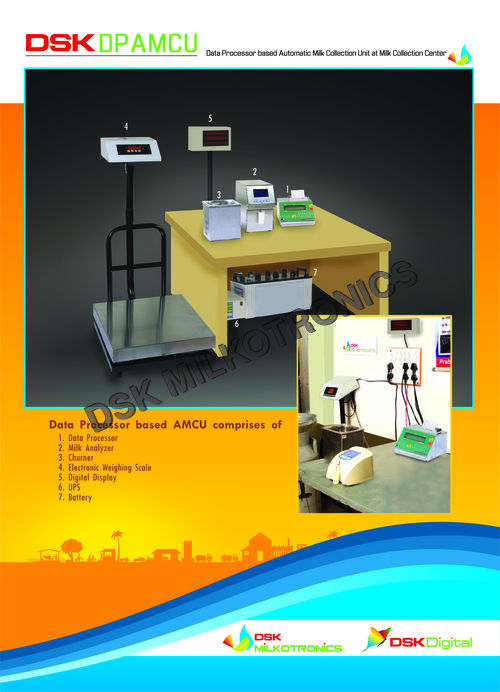

Product Overview

Key Features

DSK DairyRobot Dairy Robot at Milk Collection Center Dairy Robot comprises of 1. Mobilis 2. Bi-Lingual DudhGanga Software 3. Milk Analyzer 4. Churner 5. Electronic Weighing Scale 6. Digital Display 7. Printers (4 Thermal & 80 col. DMP) 8. Can cleaning system 9. Solar Panel 10. Biometric Device 11. Splitter 12. UPS & Battery Introduction: To collect and analyze the milk using automatic robotic system along with the mechanism of automatic milk can cleaning system Working: The operator has to collect milk from the farmers which they pour it in the robot beaker. Once the START button is pressed, the robot will suck the milk sample inside the body for further testing. Internally, the sample will get processed through various phases. The stir process will be performed automatically. The operator has to input the settings for analyzer testing. The milk will be analyzed internally. The result of the entire process will be stored automatically into the software system. Here, the operator has to input the farmers code in the software system. The milk sample will be withdrawn later from the backside of the robot. The print receipt will be given by the robots hand through the printer attached to it or Optionally, the message will be sent on the mobile phones through GPRS system. The robot works on battery where charging is done manually or through a solar panel. The low battery indication is triggered internally and it will display necessary indications automatically. The automatic cleaning system inserts the brush into the kettle when start cleaning is pressed on the software. It cleans the kettle thoroughly using timing cycles. The cycle time, cleaning process can be changed as on demand. Features Advantages Benefits Minimal manual interference. No installation and fittings required No need for additional manpower for daily milk collection process. Unit can be setup instantaneously More accuracy in working and high efficiency of single operator. No need for preparing furniture to accommodate all AMCU items Can fit in small area and moving platform. Easily transportable Can be used as mobile milk collection unit No need to have big infrastructure Complete hygienic system and User interaction through touch screen No multiple hands will be involved in the milk collection process No possibility of any contamination factor during the milk collection process Enclosed unit to insulate surrounding environmental problems such as dust. Cost effective with less maintenance Spillage of milk or water will not malfunction the operations Life cycle of all equipments will increase and less maintenance for devices Multitasking Milk collection to receipt can be processed simultaneously for multiple farmers Time of milk collection process can be reduced Quality of milk collected and transported to chilling centre will be in good condition which will benefit the collection centre Milk Can Cleaning Mechanism Can cleaning accessory cleans the milk cans automatically where human access is restricted This will help in maintaining good quality of milk during milk collection process

DSK Milkotronics Pvt. Ltd., Established in 1996 at Pune in Maharashtra, is a leading service provider of Dairy Equipment in India. DSK Milkotronics Pvt. Ltd. is one of Trade India's verified and trusted names for listed services. With extensive experience in the field of Dairy Equipment, DSK Milkotronics Pvt. Ltd. has made a reputed name for itself in the market with satisfactory Automatic Milk Collection System, Automatic Milk Collection Unit, BMC Data Logger, etc.

Focusing on a customer-centric approach, DSK Milkotronics Pvt. Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Get Dairy Equipment from DSK Milkotronics Pvt. Ltd. at Trade India quality-assured services.