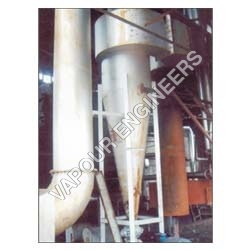

High Efficiency Cyclones - Multi-configuration Options (Twin, Quad, Double Quad) | Computer-aided Design, Optimized Gas Flow Paths, Customized Material Selection, Robust Performance For Dust Control And Product Recovery

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel/FRP |

| Type | Industrial |

| Efficiency | 99% |

| Diameter | Variable |

| Height | Variable |

| Usage | Dust collection, material recovery in various industries, including boiler, wood, sugar, metal, and abrasive applications. |

| Compliance | Local standards |

| Features | High efficiency, Low emissions, Robust design, Customizable, Easy maintenance |

Product Overview

Key Features

We can configure high efficiency cyclones into various versions - twin(two cyclones), quad (four cyclones) and double quad (Eight cyclones) with the help of computer aided time to achieve higher efficiencies.

Optimization of dimensions to ensure maximum efficiency remains the basic approach in the final selection of one of these versions. Application requirements and site conditions are other important selection factors that influence the choice of an appropriate version.

Special Features

- Computerised sizing, specially designed gas flow paths & in normal contours

- Computer aided design. Hence, efficiency and pressure drop can be precisely predicted for varying inlet parameters

- Deflectors at hopper top and a leak proof dust discharge arrangement

- Unique outlet tube design

- Application based material selection from steel to fibre reinforced plastics

- Special liners far abrasive dust laden gas and high temperature applications

We offers high Efficiency cyclones based on the technology from Trema, Germany. Unlike Conventional Cyclone having lower dust collection Efficiencies, this cyclone is an effective Solution for stringent particulate pollution control and material recovery. Cyclone has been used with great success in many dust control and product recovery applications worldwide.

In a cyclone, dust laden gas enters the upper cylinder tangentially and moves down the conical section in a spiral path. The centrifugal force thus developed makes the dust particles move radically outward. They than strike the wall and drop out of the gas stream into the hopper. Clean gas flows out through the exit tube.

Designing Cyclone is a state-of-art technique. Specific application parameters like the dust load, gas velocity, dust characteristics, particle size distribution and the overall system decide the optimum cyclone geometry and the internals. This ensure a high collection efficiency, enhanced product recovery and very low emission levels.

Advantages

- Minimize pollution due to particle re-entrainment in gas stream

- High collection efficiency, low emission levels

- Efficiency can be increased to meet future norms without major structural changes

- Ability to handle variety of dust ranging from abrasives to food grade materials

- Rebust and wear resistant construction. Enhanced life of internals

- Customized cyclone for every application

- Effective at partial loads, too

- No maintenance required

Applications

- Boiler : Coal, husk, bagasse and other solid fuel

- Wood products : Saw dust and wood ash

- Sugar industry : Sugar dust and bagasse

- Metal fines and Steel industry : Alluminum dust, copper chips and other metal dusts

- Abrasives and sand application : Fluid bed dryer, foundry sand and sand blast system

- Fabric, Lint paper : Synthetic fiber, fiberglass and fibrous material like cotton/wool/polyester/nylone etc

- Plastics, resins and synthetic : PVC and foam rubber

Company Details

Focusing on a customer-centric approach, VAPOUR ENGINEERS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Pollution Control & Monitoring Equipment in bulk from VAPOUR ENGINEERS at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Establishment

1985

GST NO

24AALFV0790M2ZN

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24AALFV0790M2ZN

Ahmedabad, Gujarat

Proprietor

Mr. Vimal Shah

Address

Plot No.D-103, Goyal Complex, Bodakdev, Ahmedabad, Gujarat, 380051, India

pollution control equipment in Ahmedabad

Report incorrect details