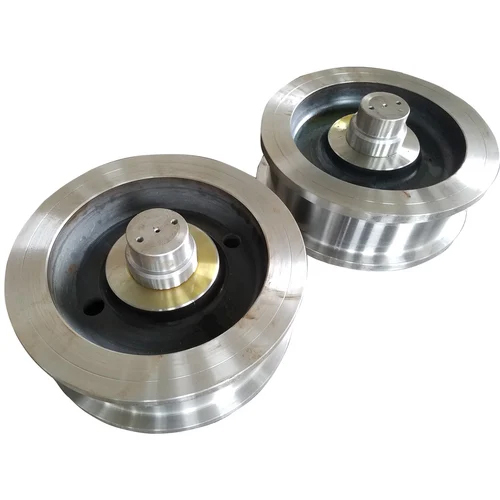

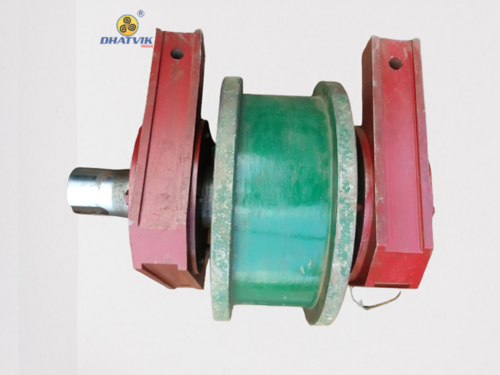

Crane Rail Wheel Assembly - Cast Iron, Multi-size Configuration, Red And Black Finish | High Load Capability, Wear Resistance, Optimal Heat Treatment

Price: 300 USD / Set

Get Latest Price

Minimum Order Quantity :

1 Set

In Stock

Product Specifications

| Usage | Industrial Use |

| Product Type | Crane wheel assembly |

| Condition | New |

| Color | Red and Black |

| Size | Multiple |

| Material | Cast Iron |

| Application | Construction |

| FOB Port | Shanghai |

| Supply Ability | 5000 Per Month |

| Delivery Time | 30 Days |

| Sample Available | Yes |

| Sample Policy | Sample costs shipping and taxes has to be paid by the buyer |

| Main Export Market(s) | Asia, Australia, North America, Middle East, Africa |

Product Overview

Key Features

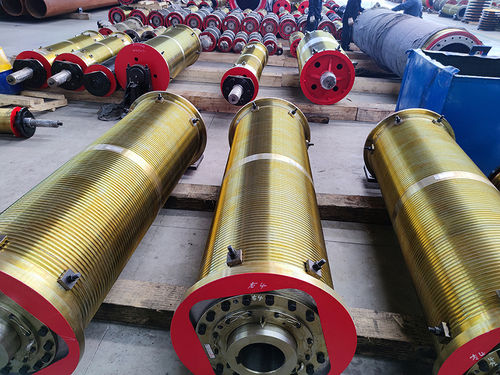

As integral components within the crane traveling mechanism, Crane Rail Wheels play a pivotal role in various lifting machines, including single-girder overhead cranes, double-girder overhead cranes, gantry cranes, port cranes, and other rail-mounted material handling equipment. These wheels come in a range of configurations, encompassing single-flange wheels, double-flange wheels, and other specialized nonstandard designs. The materials used in the construction of these wheels include 2CrMo4, ZG340-640, ZG50SiMn, 65Mn, 42Cr, etc., and more. At Purui, we employ diverse techniques tailored to the specific materials, expertly controlling the quenching and tempering temperatures to achieve the desired metallographic structure and optimal mechanical properties.

We employ two distinct heat treatment methods customized to specific requirements:

The 1st method applies hardening and tempering yielding a wheel surface hardness of HB300-380, primarily suitable for standard crane products.

In the 2nd method, surface medium frequency quenching and tempering result in a wheel surface hardness of HB300-380 or HRC50-56, ideal for products requiring low wheel center hardness with high wheel surface hardness, and when complete heat treatment is not feasible.

To minimize the risk of flange wear, breakage, and mechanical overload, while maximizing the longevity of the wheels, crucial factors like design, wheel material, wheel diameter, wheel flange design, wheel tread profile, wheel hardness, bearing type, and heat treatment must be evaluated before finalizing the combination. Purui adopts superior material, and advanced heat treatment processes to achieve higher load capability, wear resistance, ductility, and impact resistance. That's what makes them durable and dependable in the traveling mechanism of lifting, building material, metallurgy, mining, electricity, chemical, and environment protection industries.

We employ two distinct heat treatment methods customized to specific requirements:

The 1st method applies hardening and tempering yielding a wheel surface hardness of HB300-380, primarily suitable for standard crane products.

In the 2nd method, surface medium frequency quenching and tempering result in a wheel surface hardness of HB300-380 or HRC50-56, ideal for products requiring low wheel center hardness with high wheel surface hardness, and when complete heat treatment is not feasible.

To minimize the risk of flange wear, breakage, and mechanical overload, while maximizing the longevity of the wheels, crucial factors like design, wheel material, wheel diameter, wheel flange design, wheel tread profile, wheel hardness, bearing type, and heat treatment must be evaluated before finalizing the combination. Purui adopts superior material, and advanced heat treatment processes to achieve higher load capability, wear resistance, ductility, and impact resistance. That's what makes them durable and dependable in the traveling mechanism of lifting, building material, metallurgy, mining, electricity, chemical, and environment protection industries.

Company Details

Purui Precision Machinery, Established in 2001 at Xinxiang in Henan, is a leading Exporter,Manufacturer of Cranes in China. Purui Precision Machinery is one of Trade India's verified and trusted sellers of listed products. With extensive experience in supplying and trading Crane Travelling Wheel Assembly, Purui Precision Machinery has made a reputed name for itself in the market with high-quality Crane Duty Gearbox, Crane Travelling Wheel Assembly, Forging Crane Hook With Large Wwl, etc.

Focusing on a customer-centric approach, Purui Precision Machinery has a pan-India presence and caters to a huge consumer base throughout the country. Buy Cranes in bulk from Purui Precision Machinery at Trade India quality-assured products.

Focusing on a customer-centric approach, Purui Precision Machinery has a pan-India presence and caters to a huge consumer base throughout the country. Buy Cranes in bulk from Purui Precision Machinery at Trade India quality-assured products.

Business Type

Exporter, Manufacturer

Employee Count

400

Establishment

2001

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Xinxiang, Henan

Sales Manager

Mr. Ryan Feng

Address

No. 7 Duchang Road, Nanpu Street, Changyuan City, Xinxiang, Henan, 453400, China

Report incorrect details