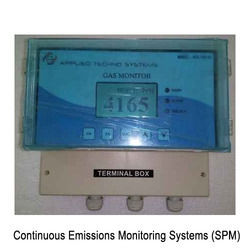

Continuous Emission Monitoring System - Advanced Multi-parameter Gas Analysis, Real-time Data Acquisition And Processing | So2, Nox, O2, Dust Measurement Capabilities, Humidity Variation Adaptation

Price:

Get Latest Price

In Stock

Product Specifications

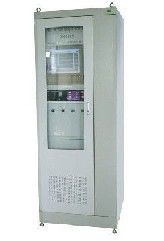

| Dimensions | 1000 x 500 x 200 mm |

| Weight | 150 kg |

| Power | 220V AC |

| Accuracy | +/- 2% |

| Materials | Steel, electronics |

| Communication | Ethernet, Modbus |

| Usage | Power plant emissions monitoring, waste incineration monitoring, and industrial process monitoring. |

| Features | Real-time monitoring, Precise analysis, Data acquisition, Emission control, Compliance ensured, Efficient operation |

Product Overview

Key Features

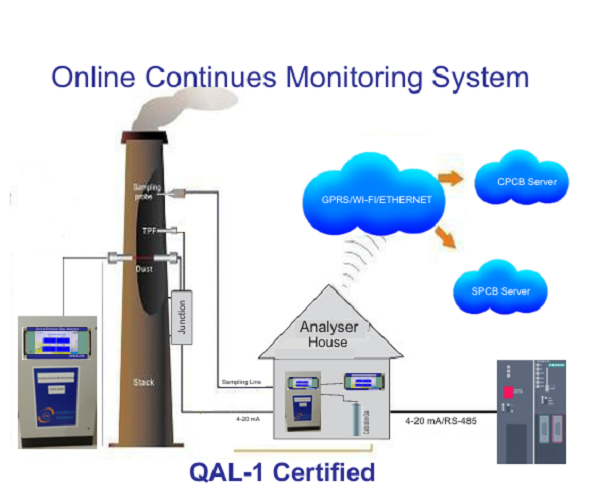

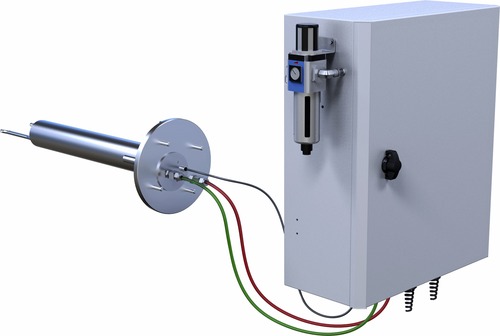

CEMS has four basic parts: the dust monitoring subsystem, gaseous pollutants monitoring subsystem, flue gas parameter monitoring subsystem, system control and data acquisition and processing subsystem. It can monitor SO2, NOx, O2, dust, temperature, pressure, flow rate and other parameters such as HCl, HF, CO, CO2 for specific occasions. After dedusting by sampling probe, sampling by heating pipe, dehydration and cooling by two-step condensing, the measured gas is analyzed by the heated gas analysis module (TDLAS and DOAS technique).It is an effective solution to solve the technical problem that great humidity variation of the waste incineration and other occasions lead to measuring data fluctuation.

Applications

This product can be widely applied in the following:

Flue gas continuous emission monitoring ( CEMS ) for the power plants (analyze SO2, NO, NO2 and O2 )

DeSOx process monitoring (analyze SO2 and O2)

DeNOx process monitoring (analyze NO, NO2, NH3 and O2)

Waste incineration flue gas continuous emission monitoring (analyze SO2, NO, NO2 and O2)

Trace Cl2 analysis of the PVC process and titanium dioxide production process for chlor-alkali plants (analyze Cl2)

Sulfur recovery process gas analysis (analyze SO2 and H2S)

Company Details

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

600

Establishment

2008

Working Days

Monday To Friday

Certification

ISO9001:2008; ISO14001:2015; TUV EMC

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Hangzhou, Zhejiang

Director

Ms Shaproo

Address

7th Floor, 2nd Building Taiheng Mansion, NO. 22, Zhiren Street, Binjiang District, Hangzhou, Zhejiang, 510053, China

continuous emission monitoring systems in Hangzhou

Report incorrect details