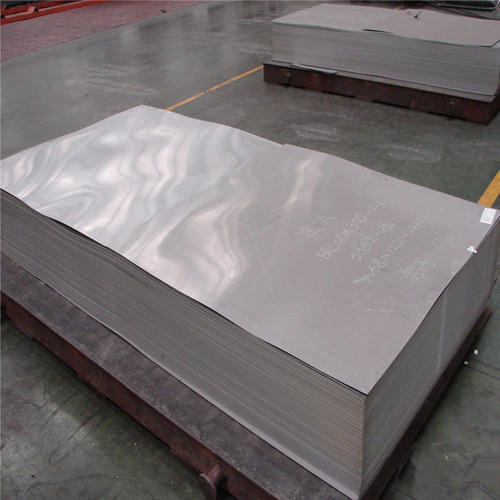

Cold Rolled Steel Sheets By Bansal Brothers

Price:

Get Latest Price

Minimum Order Quantity :

05

In Stock

Product Specifications

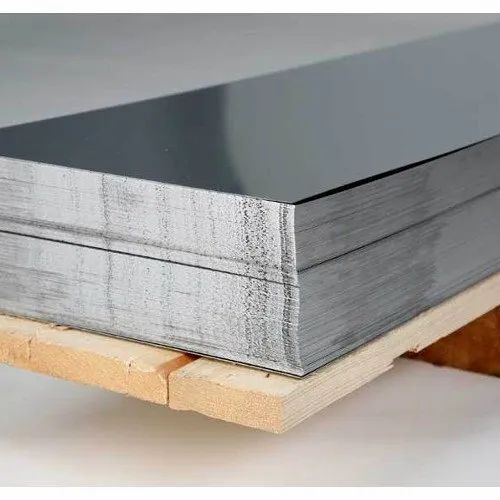

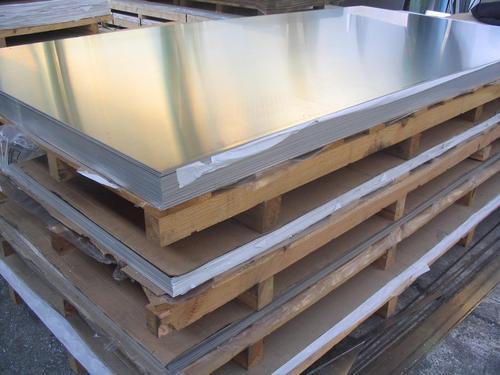

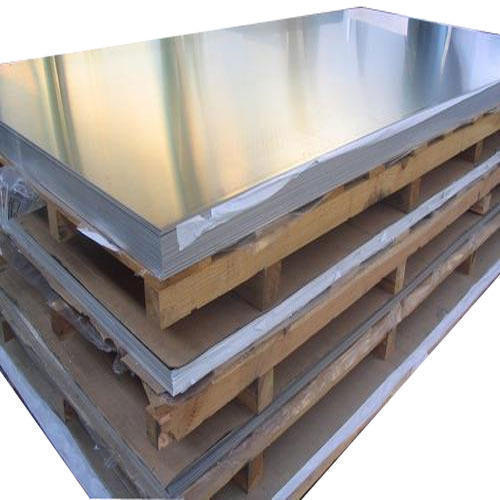

| Material | Cold Rolled Steel |

| Thickness | 0.4-3.2mm |

| Width | Variable |

| Grade | DQ,CQ |

| Surface Finish | Smooth |

| Application | Automotive, Furniture |

| Coils | Yes |

| Features | High Strength, Rugged, Impeccable Finish, Easy Install |

| Payment Terms | Others, Cash in Advance (CID), Cheque |

| Delivery Time | 07 Days |

| Sample Policy | Free samples are available |

| Main Domestic Market | All India |

Product Overview

Key Features

We are noted as a leading entity in this firm, instrumental in putting forward top-notch grade Cold Rolled Steel Sheets for our valued patrons. The offered sheets are manufactured by a crew of adept professionals using quality approved steel. These sheets are extensively used in various industries for manufacturing electrical panel and auto components. Apart from this, the provided Cold Rolled Steel Sheets are available at marginal prices for valued clients.

Key Features:

- Ruggedness

- High strength

- Impeccable finish

- Easy to install

Cold Rolled Steel Sheets are CR steel sheets used in various industries as per their requirements. We are a renowned supplier of the same for our customers. . Cold Rolled Steel Sheets go through various quality tests to ensure them in conformity with the market laid norms and standards. We offer these sheets at highly cost- effective prices in the market.

| Application | Cold Rolled Steel | Hot Rolled Steel |

| Auto | Yes | Yes |

| Direct Furniture | Yes | Yes |

| Electrical Panel | Yes | Yes |

| Gen. Engg | Yes | Yes |

| Genset | Yes | Yes |

| Lifts | Yes | Yes |

| Packaging | Yes | |

| Stamping & Electrical | Yes | |

| Tubes | Yes | Yes |

Technical Specification :

| Application Segment | Automotive | Panel | Furniture | General Engineering | ||||||||||||||||

| TDC NO. | AU03 | AU09 | XA31x4 | XA37x4 | PN02 | PN03 | PN04 | TR08x1 | TR15 CQ | XT07x4 | ||||||||||

| Grade | DQ | EDD | DQ | DQ | DQ | DQ | DQ | CQ | CQ | CQ | ||||||||||

| Dimensional | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max |

| TDC No. | 0.4 | 3.2 | 0.4 | 3.2 | 0.4 | 1.5 | 1.5 | 2.5 | 0.8 | 3.2 | 0.8 | 2.5 | 0.8 | 1.6 | 0.35 | 1.2 | 0.4 | 3.2 | 0.4 | 2.5 |

| Grade | 1000 | 1540 | 1000 | 1525 | 1000 | 1270 | 1000 | 1270 | 1000 | 1540 | 1000 | 1525 | 1000 | 1525 | 900 | 1250 | 1000 | 1540 | 1000 | 1270 |

| Dimensional | 0.5% on Central Line Thickness | 0.5% on Central Line Thickness | 0.5% on Central Line Thickness | 0.5% on Central Line Thickness | 0.5% on Central Line Thickness | 0.5% on Central Line Thickness | 0.5% on Central Line Thickness | 0.5% on Central Line Thickness | 0.5% on Central Line Thickness | 0.5% on Central Line Thickness | ||||||||||

| Thickness Range (mm) | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||||||||||

| Width Tolerance Min (+Ve) | 12 | 3 | 20 | 20 | 12 | 3x1/0.5x2 | 12x3 / 3x1 | 12 | 12 | 20 | ||||||||||

| Model of Forming | Drawing | Bending | Drawing | Drawing | Bending | | Bending | Bending | Bending | Bending | Bending | | | |||||||

| Chemistry | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max |

| %C | 0.035 | 0.07 | 0.025 | 0.05 | 0.02 | 0.07 | 0.02 | 0.07 | 0.02 | 0.06 | 0.02 | 0.06 | 0.02 | 0.06 | | 0.1 | 0.035 | 0.1 | 0.045 | 0.1 |

| % Mn | 0.2 | 0.4 | | 0.2 | 0.1 | 0.4 | 0.01 | 0.35 | 0.1 | 0.25 | 0.1 | 0.25 | 0.1 | 0.25 | 0.4 | 0.6 | 0.3 | 0.6 | 0.25 | 0.6 |

| % Si | | 0.04 | | 0.015 | | 0.04 | | 0.03 | | 0.03 | | 0.03 | | 0.03 | | 0.5 | | 0.1 | | 0.1 |

| % S | | 0.02 | | 0.012 | | 0.02 | | 0.015 | | 0.015 | | 0.015 | | 0.015 | | 0.025 | | 0.4 | | 0.05 |

| % P | | 0.025 | | 0.015 | | 0.025 | | 0.025 | | 0.025 | | 0.025 | | 0.025 | 0.02 | 0.045 | | 0.4 | | 0.045 |

| N ( ppm) | | 60 | | 55 | | 60 | | 60 | | 60 | | 60 | | 60 | | | | | | |

| % AI | 0.02 | | 0.025 | 0.06 | 0.02 | | 0.02 | | 0.021 | 0.06 | 0.021 | 0.06 | 0.021 | 0.06 | 0.02 | 0.07 | | | | |

| % B | | | | | | | | | 0.002 | | 0.002 | | | | | | | | | |

| Mechanical Properties | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max |

| YS (Mpa) | 140 | 220 | | 180 | 140 | | 140 | | | 270 | | 270 | | 270 | | 240 | | 270 | | |

| UTS (Mpa) | 280 | | 275 | 350 | 280 | | 280 | | 270 | 410 | | | 270 | 410 | | | | | | |

| % EI | 35 | | 45 | | 35 | | 35 | | 30 | | | | 30 | | | | | | | |

| Hardness (HRB) | | 50 | | 40 | | 55 | | 50 | | 55 | | 55 | | 55 | 55 | 65 | 55 | 65 | 50 | 65 |

| Bend | ok | | ok | | ok | | ok | | ok | | ok | | ok | | ok | | ok | | ok | |

| ECV (mm) | 9.1 | | | | | | | | | | | | | | | | | | | |

| Surface characteristics | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max |

| Ra | 0.8 | 1.6 | 0.8 | 1.2 | 0.8 | 1.6 | 0.8 | 1.6 | 0.8 | 1.4 | 0.8 | 1.4 | 0.8 | 1.4 | 0.6 | 1.6 | 0.6 | 1.6 | 0.6 | 1.6 |

| R.P. Oil Type | yes | | yes | | yes | | yes | | yes | | yes | | yes | | yes | | yes | | yes | |

| Shape | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max |

| Waviness (mm / 550mm) | | 8 | | 5 | | 10 | | 10 | | 4 | | 3 | | 3 | | 8 | | 8 | | 10 |

| Central Buckle (mm / 500mm) | | 8 | | 5 | | 8 | | 8 | | 4 | | 3 | | 3 | | 8 | | | | 8 |

| Comber (mm / 1000mm) | | 1 | | 1 | | 1 | | 1 | | 1 | | 1 | | 1 | | 1 | | 1 | | 1 |

Standard With & thickness matrix :

| Standard widths (mm) | 1000 | 1120 | 1250/1270 | 1320 | 1420/1450 | 1540 |

| Standard Thickness (mm) Possible for the Width | 0.40 | 0.40 | | | | |

| 0.45 | 0.45 | 0.45 | | | | |

| 0.50 | 0.50 | 0.55 | 0.55 | | | |

| 0.60 | 0.60 | 0.60 | 0.60 | 0.60 | | |

| 0.63/0.65 | 0.63/0.65 | 0.63/0.65 | 0.63/0.65 | 0.63/0.65 | | |

| 0.70 | 0.70 | 0.70 | 0.70 | 0.70 | 0.70 | |

| 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | |

| 0.80 | 0.80 | 0.80 | 0.80 | 0.80 | 0.80 | |

| 0.90 | 0.90 | 0.90 | 0.90 | 0.90 | 0.90 | |

| 0.95 | 0.95 | 0.95 | 0.95 | 0.95 | 0.95 | |

| 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | |

| 1.10 | 1.10 | 1.10 | 1.10 | 1.10 | 1.10 | |

| 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | |

| 1.50 | 1.50 | 1.50 | 1.50 | 1.50 | 1.50 | |

| 1.55 | 1.55 | 1.55 | 1.55 | 1.55 | 1.55 | |

| 1.60 | 1.60 | 1.60 | 1.60 | 1.60 | 1.60 | |

| 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | |

| 2.50 | 2.50 | 2.50 | 2.50 | 2.50 | 2.50 | |

| 3.00 | 3.00 | 3.00 | 3.00 | 3.00 | 3.00 |

Coil & Bundle Weights :

| 1000 mm | 19 Tons |

| 1120 mm | 21 Tons |

| 1250 mm / 1270 mm | 24 Tons |

| 1320 mm | 25 Tons |

| 1420 mm / 1450 mm | 26 Tons |

| 1540 mm | 28 Tons |

Company Details

Focusing on a customer-centric approach, BANSAL BROTHERS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Steel & Stainless Steel Products & Components in bulk from BANSAL BROTHERS at Trade India quality-assured products.

Business Type

Distributor, Supplier, Trading Company, Wholesaler

Employee Count

20

Establishment

1975

GST NO

07AAAFB5367K1ZC

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 07AAAFB5367K1ZC

New Delhi, Delhi

Mr. Bharat Bansal

Address

Head Office : X-26, Loha Mandi, Naraina, New Delhi, Delhi, 110028, India

Report incorrect details