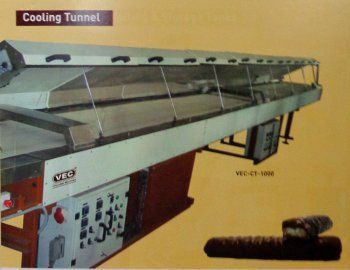

Chocolate Cooling Tunnel Machine

Price:

Get Latest Price

In Stock

Product Specifications

| Product Type | Chocolate Cooling Tunnel Machine |

| General Use | Chocolate Cooling |

| Material | Stainless Steel |

| Computerized | No |

| Automatic | Yes |

| Control System | PLC Control |

| Voltage | 220/380 Volt (v) |

| Color | Silver |

| Payment Terms | Telegraphic Transfer (T/T) |

| Delivery Time | 1 Week |

| Packaging Details | Industry Standard |

| Main Domestic Market | All India |

Product Overview

Key Features

Here are some key features and aspects of a chocolate cooling tunnel machine:

1. **Design and Structure:**

- **Belt System:** Chocolate cooling tunnels typically have a conveyor belt system that carries the chocolate through the cooling process.

- **Insulation:** The tunnel is often well-insulated to maintain a consistent and controlled temperature.

- **Length and Configuration:** The length and configuration of the tunnel can vary based on production needs and the type of chocolate being processed.

2. **Temperature Control:**

- **Zones:** Cooling tunnels are divided into different zones, each with its own temperature control. This allows for a gradual cooling process.

- **Adjustability:** Temperature settings are adjustable to accommodate different chocolate formulations.

3. **Airflow and Ventilation:**

- **Forced Air:** Tunnels use forced air circulation to ensure uniform cooling.

- **Ventilation System:** Efficient ventilation systems help remove excess heat and maintain the desired temperature.

4. **Speed Control:**

- **Adjustable Speed:** The speed of the conveyor belt can usually be adjusted to control the cooling time and achieve the desired chocolate properties.

5. **Hygiene and Maintenance:**

- **Easy Cleaning:** The design often facilitates easy cleaning to meet hygiene standards.

- **Maintenance:** Regular maintenance is essential to ensure the machine functions optimally.

6. **Additional Features:**

- **Chocolate Curtain:** Some cooling tunnels may have a chocolate curtain at the entrance and exit to prevent temperature fluctuations and maintain the cooling environment.

- **Monitoring Systems:** Advanced models may have monitoring systems to track temperature, humidity, and other relevant parameters.

7. **Capacity and Throughput:**

- **Production Capacity:** The machine's capacity is an important consideration for manufacturers, and it should align with the required production volume.

When using a chocolate cooling tunnel, it's important to follow proper operating procedures to ensure the quality of the chocolate product. Manufacturers often integrate cooling tunnels into larger chocolate production lines for efficiency and consistency in the chocolate manufacturing process.

Company Details

Business Type

Manufacturer, Distributor, Supplier, Trading Company

Employee Count

10

Establishment

2018

Working Days

Monday To Sunday

GST NO

36AEVPU5533P1ZC

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 36AEVPU5533P1ZC

Hyderabad, Telangana

Proprietor

Mr Upendar

Members since

3 Years

Address

12-2/488/A/1, Plot No.488 & 489, Survey No.277 to 285, Sree Nagar Colony,Nagaram Municipality, Rampally (V), Keesara (M), Hyderabad, Medchal-Malkajgiri Dist. Hyderabad, Telangana, 501301, India

chocolate cooling tunnel in Hyderabad

Report incorrect details