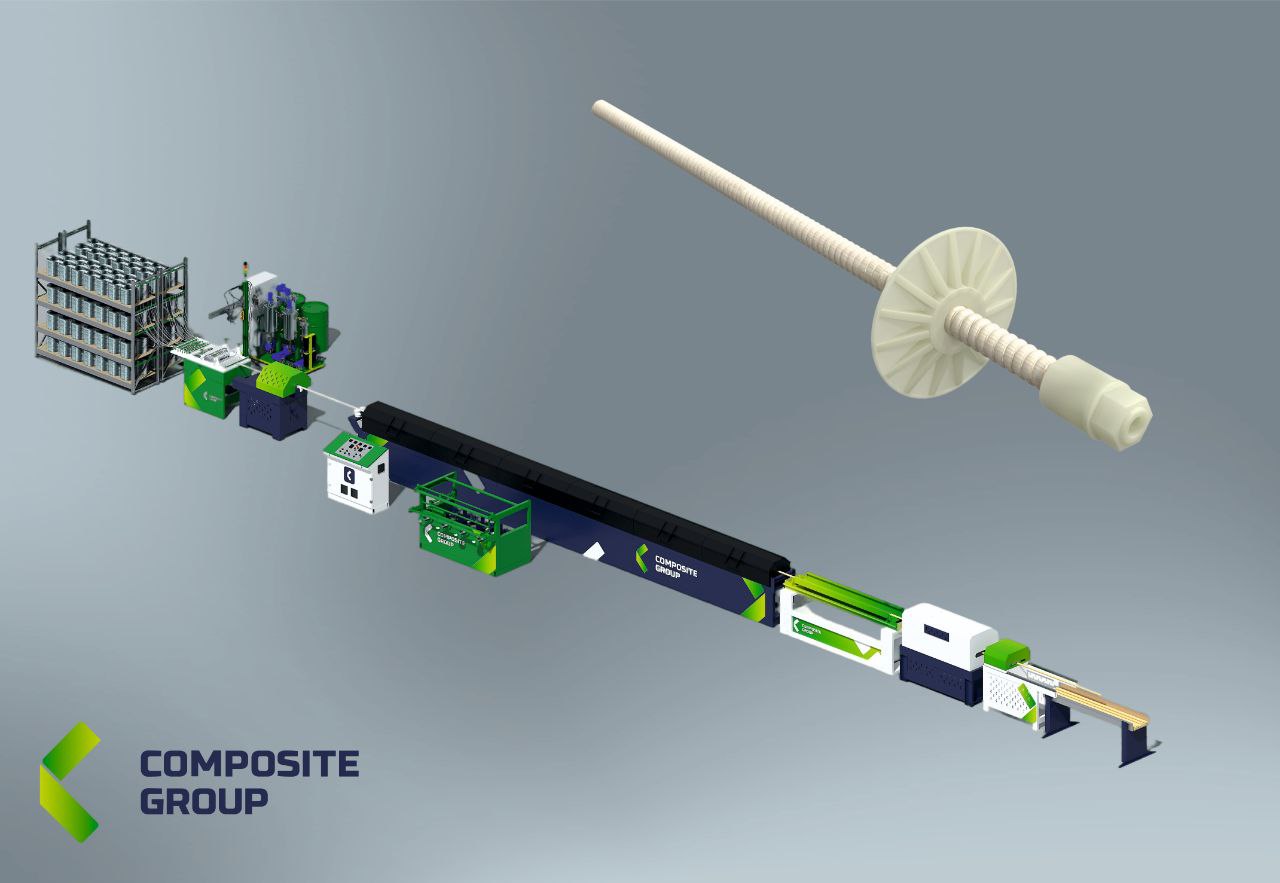

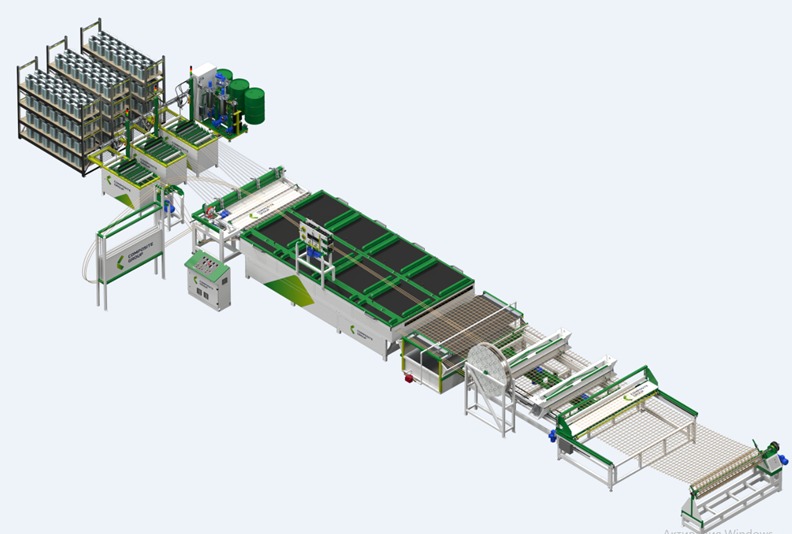

Cg Production Line For Fiber Reinforced Polymer Mesh - Height: 3500 Millimeter (Mm)

Price: 200000 USD / Unit

Get Latest Price

Minimum Order Quantity :

1 Unit

In Stock

Product Specifications

| Height | 3500 Millimeter (mm) |

| Weight | 15000 Kilograms (kg) |

| Product Type | Equipment |

| Length | 22090 Millimeter (mm) |

| Width | 3000 Millimeter (mm) |

| General Use | CG Production Line |

| Application | Production of fiberglass mesh |

| Technique | Method of twising rods with an automatic feed of the transverse bars directly from roving, no need to pre-fabricate cross bars |

| Automatic | Yes |

| Feature | Simple Control, Stable Operation, Lower Energy Consumption |

| Color | Customized |

| FOB Port | Russian ports |

| Payment Terms | Letter of Credit (L/C), Days after Acceptance (DA), Delivery Point (DP), Telegraphic Transfer (T/T) |

| Supply Ability | 10 Per Year |

| Delivery Time | 90 Days |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | Polyfilm, wooden frame (crate) |

| Main Export Market(s) | Asia, Central America, Western Europe, Middle East, Africa |

| Main Domestic Market | All India |

| Certifications | ISO 9001 2015: TUV SUD Germany 2017, TUV Austria 2020, 2023, 2025 |

Product Overview

Key Features

Composite Group Chelyabinskis constantly developing technologies for the production of composite materials.Company manufactures 6 different types of machine lines, has already developed three generations of production of them, the first and the second, were successfully manufactured and delivered to companies in ten countries.

CG Production line is designed for manufacturing of Fiber Reinforced Polymer Mesh made of glass, basalt and carbon fiber roving.

The mainfeaturesof a line

1)Manufacture mesh by method of twisting rods with an automatic feed of the transverse bars directly from roving, no need to pre-fabricate cross bars

2)1000/2000/2500/3000/3500 can be produced for a client (difference is in mesh width)

3)Rod diameter: from 2 to 10mm or 4mm to 12mm

4)Produces up to 4000 m2 per 24h (3mm rod,200 x 200 mm)

5)Finished products are resistant to corrosion, have high tensile strength

Requirements:

Required space for a line 450 m2

Electricity consumption: 25-50 kw/h

Power supply: 50+-1Hz, 380V

Water consumption: 2 m3

2 operators per shift

The composite material produced on this production is cheaper than steel analogues for the end user by 10%-20% in any country of the world. Due to the fact that composite materials are 4-10 times lighter, than steel, it's possible to save up to 90% on delivery.

The fiberglass products are not subject to corrosion, they are not afraid of aggressive media such as alkalis, acids, sea and fresh water, agricultural waste, automotive and industrial emissions.

The composite material is radio transparent. Moreover, it changes its volume under the influence of temperature differences synchronously with concrete, as a result, doesn't lead to the formation of microcracks. Besides, when using composite reinforcements and bonds, "heat and cold bridges" are not formed, hence, there will be no condensate.

The main characteristic for any reinforcing material is the tensile strength, for a composite produced using Russian technology, this indicator is 2-3 times higher than for steel analogues. The requirements of the Russian standard are at least 1000 MPa, our company's technologies, our machine ow us to reach 1400 MPa.

Composite Group productscan be used:

1)in the construction of road transport infrastructure, marine and port facilities, mines, agricultural facilities, urban engineering infrastructure;

2)facilities operated in conditions of high electromagnetic fields and potential differences, exposed to leakage currents;

3)during the construction of chemical production facilities

4)land reclamation;

5)in concrete structures, which are characterized by a reduced protective effect compared to steel reinforcement;

6)in the production of earthworks and soil strengthening;

7)in multilayer heat-saving enclosing structures;

8)during the reconstruction, repair and restoration of ings and structures.

Company Details

"Composite Group Chelyabinsk" is a research and production company engaged in development of composite reinforcing materials and equipment for their manufacturing.

Composite Group manufactures non-metallic composite building materials made of fiberglass and basalt fiber, such as rebars of thin and thick diameters, anchors, flexible ties, bent elements, composite meshes. We supply our finished products to more than 20 countries around the world.

Moreover, the company is also developing technologies for the production of finished products. Composite Group manufactures 6 different types of machine lines.

The uniqueness of the technologies is confirmed by 20 patents with international priorities, which we register in 14 countries.

Composite Group is committed to high quality standards. Therefore, we are constantly improving our lines and products, as well as annually passing inspections for compliance with the international standard ISO 9001 2015. For example, we passed such inspections in 2017 in TÜV SÜD Germany, in 2020, 2023 and 2025 in TÜV SÜD Austria.

Business Type

Manufacturer, Supplier

Employee Count

50

Establishment

2011

Working Days

Monday To Friday

Payment Mode

Days after Acceptance (DA), Delivery Point (DP), Letter of Credit (L/C), Telegraphic Transfer (T/T)

Certification

ISO 9001 2015: TUV SUD Germany, TUV Austria

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Chelyabinsk, Cheljabinsk

Export Manager

Ekaterina Sivkova

Address

454047, Russia, Chelyabinsk Region, Chelyabinsk, 2nd Paveletskaya St. 36/1, Office 303 Chelyabinsk, Cheljabinsk, 454047, Russia

Report incorrect details