Boiler Chemicals - Multi-purpose Liquid Treatment For Phosphate Conditioning, Deoxygenation, And Sludge Control

Price:

Get Latest Price

In Stock

Product Specifications

| Color | Blue |

| Material | Plastic |

| Capacity | 25 Liters |

| Dimensions | 30x30x40 cm |

| PH Level | 7-10 |

| Density | 1.2 g/cm³ |

| Storage | Cool, dry place |

| Features | Corrosion prevention, Scale reduction, Improved efficiency, Extended lifespan, Reduced downtime, Cost savings, Enhanced safety |

Product Overview

Key Features

Relaying upon our team of adroit professional, we are able to supply an superior quality Boiler Chemicals . These chemicals are used in industries in the boiler plants. The provided chemicals are prepared by our team of adroit professionals by making use of quality tested components and latest technology according to the instruction provided by our vendor's team of skilled professionals. Our customers can purchase these Boiler Chemicals from us at reasonable price range

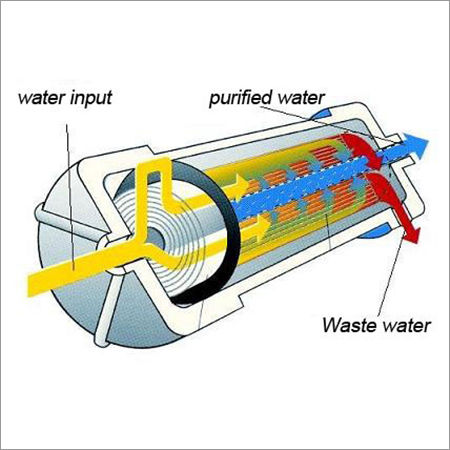

Heat transfer and steam generating efficiency are critical metrics for any steam generating system and can impact everything from fuel costs to maintenance expenses and unscheduled outages. Deposition and corrosion are two key problems that can negatively affect these metrics as well as the overall reliability of the system.

Our Treatment programs provide protection againstdepositionand scaling to improve asset reliability and efficiency of your boiler system. Treatments include All-Polymer programs as well as coordinated pH, chelant, and phosphate programs to best fit your system.

Dissolved oxygen is a constant threat to the integrity of a feedwater system, economizer, and internal boiler and condensate system surfaces. Even minor concentrations of dissolved oxygen can cause severe pitting corrosion. Because of its highly localized nature, pitting attack, caused by dissolved oxygen, can result in rapid failure of feedwater lines, economizers, boiler tubes and condensate lines. Our inorganic sulfite and our organic oxygen scavengers rapidly remove any dissolved oxygen remaining after mechanical deaeration.

Corrosion can threaten the reliability and safety of critical steam equipment, usually taking the form of acid or CO2 corrosion, dissolved oxygen attack, erosion or flow-assisted corrosion, and/or downtime/storage corrosion. If left untreated, ongoing corrosion can result in significantly higher maintenance and equipment replacement costs, reduced runtime, unscheduled outages, and lower product quality. Good steam condensate treatment can help minimize corrosion throughout the condensate system and drive overall productivity with less maintenance, downtime, and asset costs.

BWT-7000 a multi purpose liquid product used for phosphate conditioning, chemical deoxygenation, and sludge conditioning of boiler feed water.

BWT-9000 is a blend of chemicals used to supplement the normal treatment in for adjustment of pH and alkalinity in boiler blow-down water.

Company Details

Focusing on a customer-centric approach, SHRI SAI ENTERPRISES has a pan-India presence and caters to a huge consumer base throughout the country. Get Water Treatment Chemicals from SHRI SAI ENTERPRISES at Trade India quality-assured services.

Business Type

Exporter, Manufacturer, Service Provider, Distributor, Supplier

Employee Count

16

Establishment

2009

Working Days

Monday To Sunday

GST NO

24ABLPB2878D1ZV

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24ABLPB2878D1ZV

Surat, Gujarat

Director

Mr. Kirit Bhavsar

Address

F-16/2, Rang Avdhoot Society, Station Road, Town- Sachin, Surat, Gujarat, 394230, India

Report incorrect details