Blow Moulding Services

Price:

Get Latest Price

In Stock

Product Overview

Key Features

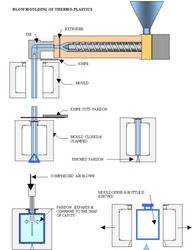

The blow molding process begins with applying heat energy to the resins thus, converting them into a molten state and forming them into a prison or preform. The prison is a tubular piece of plastic with a hole in one end in which compressed air is released. The compressed air expands the parson into the female mold cavity, while the pressure of the compressed air is maintained for a pre determined period of time, thus allowing the parson to expand and take the shape of the mold cavity. Once the plastic has cooled the mold is opened and the part is ejected.

In general, there are three main types of blow molding systems: extrusion blow molding (EBM), injection blow molding (IBM), and stretch blow molding (SBM).

Extrusion blow molding can be either continuous (where the parson is extruded continuously and separated by a hot cutter or knife) or intermittent (where the screw turns, stops and pushes the material out. If there is an accumulator head it will gather the melted material and form into a parson when enough material is accumulated)

Injection blow molding consists of two stages, injection molding of thermoplastic material into hollow tube shape called a preform and blow molding where the preform is transferred on to a metal shank called the core rod which rotates to a blow moulding station where it is inflate and cooled. This pr

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

12

Establishment

1973

Working Days

Monday To Sunday

More Product From This seller

Seller Details

Mumbai, Maharashtra

Managing Partner

Mr. Saumil Patel

Address

No. B/304, Byculla Service Industries, Dadoji Konddeo Marg, Byculla, Mumbai, Maharashtra, 400027, India

Report incorrect details