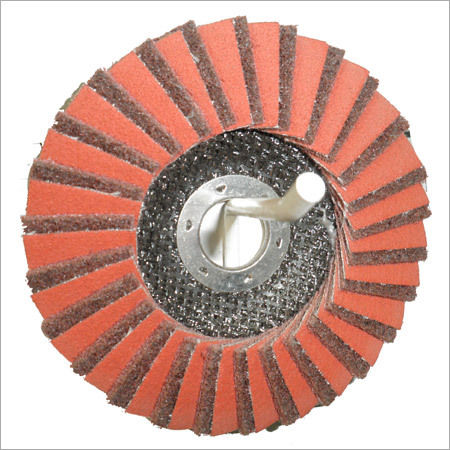

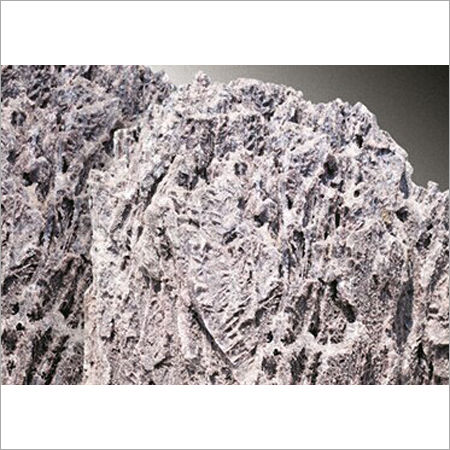

Due to our modern processing set up and quality-centric approach our firm is able to offer Black Silicon Carbide Crystal. This compound is a popular abrasive used for making abrasive machines like honing water jet cutters sandblasters and grinding wheels. The provided compound is processed by our skilled professionals using outstanding quality basic chemicals and progressive techniques in conformance with international quality industrial standards. In addition to this our clients can avail this Black Silicon Carbide Crystal from us in various packaging options at budgeted prices.Features:Precise composition blocky and sharp edged extremely hardElectrical and heat conductivity; high thermal conductivity & low thermal expansionBetter solubility non toxicResistant to acids and alkaline solutionsWhy Us?Our personnel are skilled enough to produce this products using optimum quality coke sand sawdust and a small amount of salt; obtained from trusted sources in electric resistance furnace.This crystal form mineral is checked by experts on the basis of its physical properties such as molecular weight bulk density true density thermal conductivity hardness specific gravity etc.You can use this cost-effective product in refractories construction industry bonded abrasive products and many more applications.Chemical Composition Grit Chemical Composition(% by weight) SIC() F.C() Fe2O3() F12-F90 98.5 0.20 0.60 F100-F150 98 0.30 0.80 F180-F220 97 0.30 1.20 F230-F400 96 0.40 1.20 F500-F800 95 0.40 1.20 F1000-F1200 93 0.50 1.20 P12-P90 98.5 0.20 0.60 P100-P150 98 0.30 0.80 P180-P220 97 0.30 1.20 P230-P500 96 0.40 1.20 P600-P1500 95 0.40 1.20 P2000-P2500 93 0.50 1.20