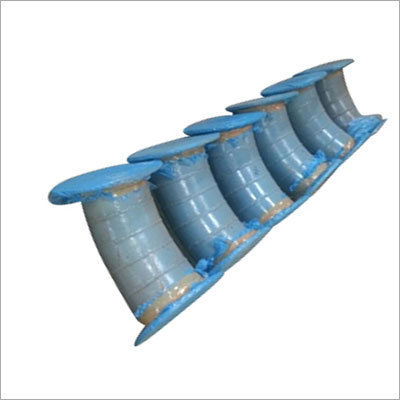

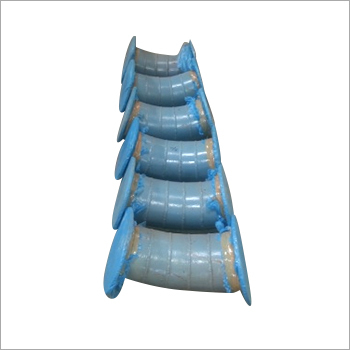

Bends And Y-pieces - Alumina Ceramic Lined, Lower Id, Ni-hard Castings | Durable Lining, Velocity Control 20-27 M/s, Enhanced Wear Resistance

Price:

Get Latest Price

Minimum Order Quantity :

1000

In Stock

Product Specifications

| Material | Alumina Ceramic |

| Lining | Ceramic Liners |

| Casting | Ni-Hard |

| Velocity | 20-27 M/S |

| Application | Lean-Phase System |

| Id | Lower |

| Type | Bends |

| Features | Wear Resistance, Durable Lining, Reduced Replacement, Velocity Control, Particle Size |

| Supply Ability | as per required Per Week |

| Delivery Time | 1 Week |

Product Overview

Key Features

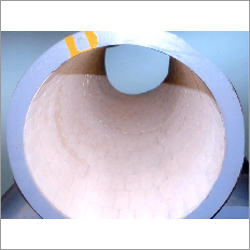

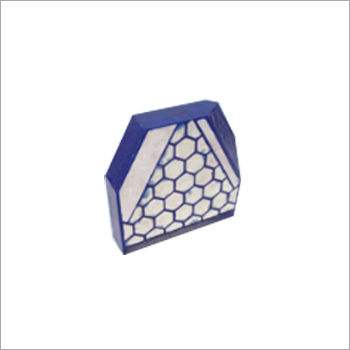

One of the major factor influencing bend wear rate is the conveying velocity of the ash, density and the ash particle size. Lean-phase system normally maintain velocity between 20-27 m/s. The metal bends and pipes required to be replaced very frequently. To check the wear bends are lined with Alumina Ceramic liners. In lower ID bends, wear resistant Ni-Hard castings are also used. In this section we will demonstrate our Alumina Ceramic lined bends.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Establishment

1961

Working Days

Monday To Sunday

GST NO

05AAACB7914R1ZB

Certification

An ISO 9001-2008 Certified Company

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 05AAACB7914R1ZB

Haridwar, Uttarakhand

Director

Mr Atul Lohia

Members since

16 Years

Address

Shiv Ganga Industrial Estate, Bhagwanpur, Haridwar, Uttarakhand, 247667, India

bend fittings in Haridwar

Report incorrect details