Stainless Steel Color Automatic Snack Food Machine

Price Trend: 1000- 8900 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Product Type | Baking Equipment |

| Material | Stainless Steel |

| Power Source | Electric |

| Flour Capacity | 800 Kg/hr |

| Bowl/Pan Size | NO |

| Automatic Grade | Fully Automatic |

| Voltage | 380 Watt (w) |

| Temperature Range | 110-180 Celsius (oC) |

| Speed | Frequency changer control speed RPM |

| Equipment Size | 18000*1200*1600mm |

| Dimension(L*W*H) | 18000*1200*1600 Millimeter (mm) |

| Weight | 1800 Kilograms (kg) |

| Color | Stainless steel color |

| Warranty | 1 year |

| FOB Port | Qingdao |

| Payment Terms | Letter of Credit (L/C), Paypal, Western Union, Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash in Advance (CID) |

| Supply Ability | 20 sets Per Month |

| Delivery Time | 30-45 Days |

| Sample Available | Yes |

| Sample Policy | Free samples are available |

| Packaging Details | Export standard |

| Main Export Market(s) | Asia, South America, Eastern Europe, Middle East, Africa |

| Main Domestic Market | All India |

| Certifications | SGS, CE |

Product Overview

Key Features

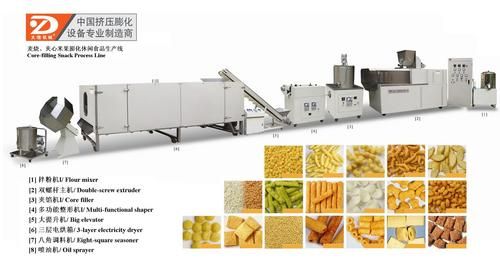

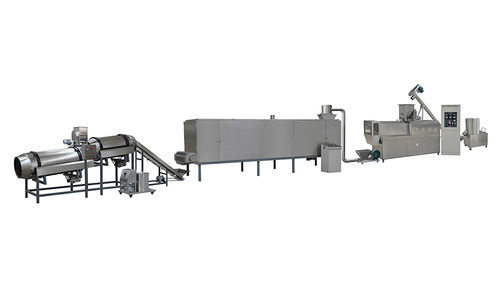

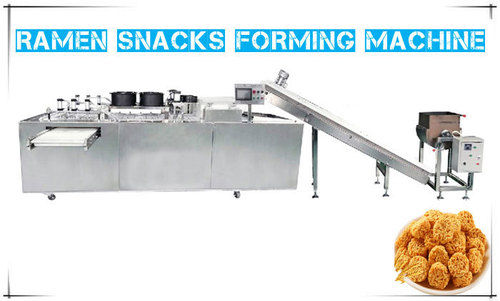

1. Brief Introduction of puffed snack food machine

Cereal snacks can be directly extruded from the extruder, dryer and flavoring machine. Puffed Cereal Snacks Machine Processing Plant can produce all kinds of snacks and different shapes by adjusting the dies from extruder. It can take corn, rice, wheat, oat, rye and other grains as materials to produce extruded snacks, with crispy taste and lively shape. Puffed Cereal Snacks Machine Processing Plant is designed according to market demand. The shapes includes cheese balls, corn curls, corn sticks, coco pops, cereal, kurkure and pellets.

2. Main Features

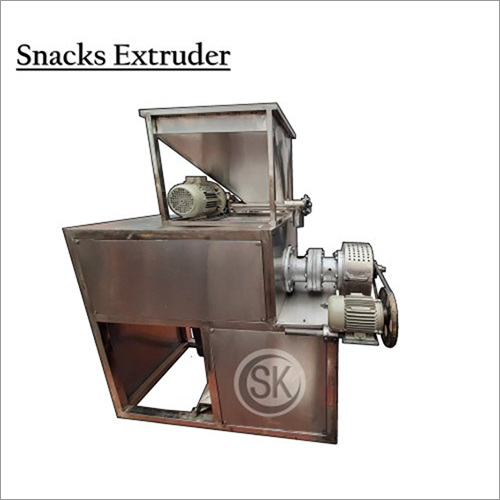

Main Material: Stainless Steel

Screw Quantity: 2

Screw Material: 38CrMoAl

Rotating Speed: Adjustable

Temperature: Adjustable

Self-cleaning Function

Forced Lubrication Function

Pasteurization Function

Flexible Collocation of Equipment

3. Puffed puffed core filler snack food machine

Production Process:

Mixer---Screw Conveyor---Extruder---Hoister---Roasting machine---Hoisting and flavoring machine--- (Packing machine)

Voltage:

220V380/400V/415V/440V

Custom-made according to customers' local voltage

Machine advantage and feature:

1. The screw is made of alloy (38CrMoAL) by nitriding process, high strength and wear-resting. And it has good self-cleaning ability and does not need to discharge or clean the barrel and screw, when roasting or replacing of materials; Segmental screw is applied to more kinds of materials and production. At the same time, it is easy to change and reduce the replacement cost.

2. It adopts speed-adjusted converter on feeding system, extrusion system and cutting system which could adjust the speed with more powerful drive, stable running, and low consumption.

3. Automatic lubrication system in gear box, it could reduce power consumption and prolong the life.

4. Radiator is increased on driving part for forced cooling effect, and it ensures extruder operate safely.

5. Barrel with water-cooled circulation, raw materials not only for corn/rice, also for wheat flour/starch with high viscosity. Different moisture-extrusion temperature ratio, whole-expanded and half expanded as different type of products.

6. Hanging mould and knife steat can increase the speed of replacing mould and knife.

Satisfied service & Turnkey Solution:

Before Purchasing: We will provide professional technical project, design service and sales consultation service to solve the customers' question and worried;

During Production: Timely updates the machine status for customer to ensure delivery time, and quality;

After Production: Machine testing video and photos will be provided for inspection, if the customer can't come;

Before & During Shipment: The machine will be cleaned and packaged before transportation; All the documents will be provided for the seller;

Installation & Training: Providing professional and expert technical engineers to supply the training and installation service;

After Sales Service: Dedicated department and engineers for providing the timely and efficient service when the clients' need, such as formula, parameters setting, and spare parts.

Machine packing & Shipping

All Machine will be cleaned and whole wraped by plastic film to avoid any scratch;

Extra Spare Parts,wires and tool box will be placed with the package;

Delivery Department and sales will check the list to avoid any missing;

All Wooden Cases for protecting the machine during long-time shipment

Company Details

Business Type

Manufacturer, Supplier, Trading Company

Employee Count

60

Establishment

2012

Working Days

Monday To Saturday

Payment Mode

Letter of Credit at Sight (Sight L/C)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Jinan, Shandong

Sales Manager

Mrs Grace King

Address

NO. 177, SHIDAI Road, PING AN Street, Changqing district, Jinan, Shandong, 250300, China

corn snacks machine in Jinan

Report incorrect details