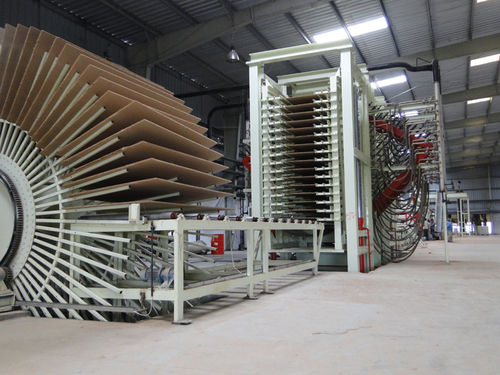

Automatic Particle Board Production Line - 10000-100000 Cbm/year Capacity, 500-2300kw Motor Power | Fully Automatic Operation, Adjustable Glue Application, Efficient Material Sizing

Price Trend: 360000.00 - 1500000.00 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Product Type | Other |

| Machine Type | Other |

| Machine Style | Other |

| Capacity | 10000-100000 cbm/year Cubic Meter (m3) |

| Voltage | 380V/415V Watt (w) |

| Power | Electric |

| Automation | Automatic |

| Motor | 500-2300kw |

| Color | As request |

| Warranty | 1 year |

| FOB Port | QINGDAO |

| Payment Terms | Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T) |

| Supply Ability | 20 Per Year |

| Delivery Time | 60-90 Days |

| Sample Available | Yes |

| Sample Policy | Sample costs shipping and taxes has to be paid by the buyer |

| Packaging Details | As request |

| Main Export Market(s) | Africa, Middle East, South America, Asia |

| Main Domestic Market | All India |

| Certifications | ISO9000 |

Product Overview

Key Features

This line is using small size of logs, branches, wood waste material like core, crushed veneer, log offcuts, plywood scrap, reed, cotton stem, cane, race straw as well as other material to produce Gradient structure and homogeneous structure high quality particle board. This kind of board is widely used in furniture, construction, packaging, and decoration.

Production process

1.Wood shaving preparation section

Option I:

Wood, twigs and other short and small materials, sent to the drum chipper feeding belt conveyor. The qualified wood chips cut by the chipper are sent to the wood chip bins for intermediate storage via the discharging belt conveyor and the bucket elevator. The chips are then made into qualified wood shavings by the ring flaker and are wind delivered to the wet shavings bin.

Option II

Wood raw materials are fed into the long log flaker by a feeding conveyor, and are cut into qualified shavings and are wind delivered to the wet shavings silo.

Option III

Long wood and other long products are sent to the long log flaker by a feeding conveyor, and are cut into qualified shavings once and is wind delivered to the wet planer bin.

Branches and other short materials, sent to the drum chipper feeding belt conveyor. The qualified wood chips cut by the chipper are sent to the wood chip bins for intermediate storage. The chips are then made into qualified wood shavings by the ring flaker and wind delivered to the wet shavings bin.

2.Drying and screening section

Quantitatively output shavings from wet bin are fed to a rotary dryer via a screw conveyor. The dried wood shavings are then sent to a screen machine for screening by a screw conveyor. A spark detection device is provided on the screw conveyor of the dryer. Once the alarm is triggered, the dry material can be automatically discharged outside the system. The selected rough shavings are re-processed into a shaving machine, and together with the sieved core layer shavings, are conveyed by a screw conveyor to air-separator. The screened qualified surface shavings are wind delivered to the surface shavings silo. The qualified air-separated shavings are sent to the core shavings store for intermediate storage. The classified coarse material is sent to the grinding machine and crushed, and then combined with the screened core layer shavings and then wind delivered to the surface shavings silo. According to the different proportions of the core layer and surface layer when different thicknesses are produced, part of coarse shavings can be quantitatively transferred to the grinding machine to make into surface shavings.

3.Glue preparation section

This section includes the preparation and delivery of paraffin emulsion and curing agent solution, additive storage and mixing glue preparation and glue system. The mixed glue is proportioned in a centralized gluing mixer. Controlled by a PLC program, the automatic metering, continuous proportion, and quantitative glue and adjustments are allowed.

4.Sizing section

Core and surface layer is sizing separately. The wood shavings are quantitatively output from the silo, passed through a vibrating feeder, and continuously weighed by a metering device and then evenly entered a ring-type mixer. The glue mixer fully mixes the incoming shavings with the atomized glue, uniformly applies the glue, and automatically adjusts the amount of glue according to the change of the amount of shavings, so as to keep the constant sizing rate.

5.Forming & hot press section

After sizing, the surface and core layer shavings are sent via belt conveyor to the mobile airflow forming machine.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

50

Establishment

1993

Working Days

Monday To Sunday

Certification

ISO9000

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Linyi, Shandong

Sales Manager

Kevin

Address

Yitang town, Lanshan district, Linyi city, Linyi, Shandong, 276000, China

particle board machine in Linyi

Report incorrect details