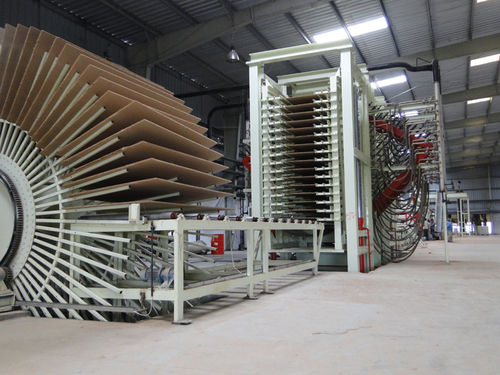

Customized 150000cbm Particleboard Production Machinery Line

Price Trend: 180000.00 - 800000.00 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Product Type | Woodworking Machine |

| Machine Type | Wood Lathe |

| Machine Style | Other |

| Power | Electric |

| Automation | Automatic |

| Color | customized |

| Warranty | 1 year |

| FOB Port | Qingdao China |

| Payment Terms | Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Paypal, Others, Telegraphic Transfer (T/T) |

| Supply Ability | 50set/Year Per Year |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | Standard Export Packing |

| Main Export Market(s) | Australia, Middle East, Western Europe, Africa, South America, Asia, North America |

| Main Domestic Market | All India |

| Certifications | CE, ISO, FDA |

Product Overview

Key Features

PB line based on wood as raw materials, shavings, glue, auxiliary equipment, hot pressed density 550-750kg / M 3 man-made sheet. It has a fine smooth surface structure of the core layer gradient, and has good heat insulation, sound insulation and good machining properties, is widely used in manufacturing furniture, high-end cabinets, speakers, and other interior construction and transport. We produce an annual output of 30000-60000 cubic meters of particle board equipment, in a dry, auxiliary equipment, hot press has done a great section in the technical modifications, reduce investment, improve the quality of the products.

1) Chip preparation section

Raw material is reduced into qualified chips by the drum chipper, then the chips are transported to the chip bin, and then feed to the knife-ring flaker by which the chips are turned to flakes,then the flake stored in wet flake bin.

2) Drying and sifting section

The flskes discharged from the wet flake bin are conveyed to the rotary dryer. Qualified core flakes are stored in core flake bin; oversize flakes are send to mill to be re-crushing, and transported to surface flake bin.

3) Forming and hot-pressing section

The surface and core flakes are sent into classi-forming machine, and forming on the mat conveyor uniformly. After process of metal remover , pre-press, lengthwise saw, cross saw, accelerate conveyor,scaling conveyor , storing conveyor and loading conveyor,mats are transported to carrier and then to hot pressing. Rough boards after pressing are pushed to unloader via pallet.

4) Cooling and sizing section

The rough board is conveyed to star-cooler for cooling ,then the rough board goes through side trimming saw and become a qualified particle-board, stacked on the hydraulic lift.

5) Sanding section

The board are sanded,checked and stored.

PLC control is used in mat-forming section.

Company Details

Focusing on a customer-centric approach, NEW TIANLI MACHINERAY CO. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Woodworking Machinery in bulk from NEW TIANLI MACHINERAY CO. LTD. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier, Trading Company

Employee Count

20

Establishment

1991

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Linyi, Shandong

Sales Person

Mr. Jake Lau

Address

Room 1001A A A Tongda Fortune Plaza, Beiyuan Road, Linyi, Shandong, 276000, China

particle board machine in Linyi

Report incorrect details