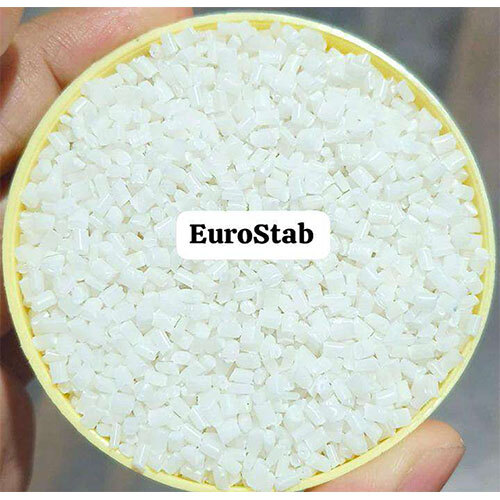

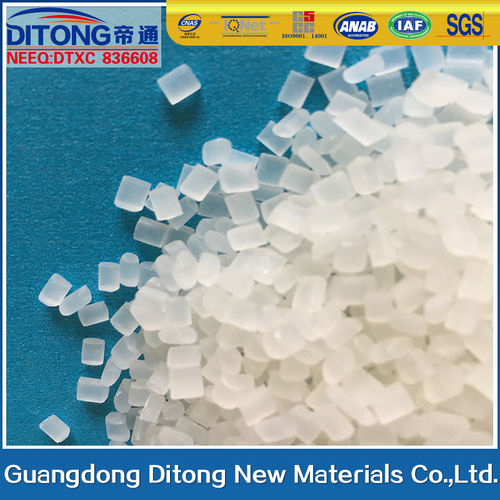

Antifog Masterbatch - Translucent Granules, 0.89~0.93 G/cm³ Density, Food Safe Additive, Quick Migration And Lasting Anti-fog Effect

Price:

Get Latest Price

Minimum Order Quantity :

10

In Stock

Product Specifications

| Carrier | PP |

| Usage | Synthetic Resin and Plastics |

| Type | functional masterbatch |

| Application | Film, Extrusion Molding, Blow Molding |

| Appearance | Granules |

| Density | 900 Kilogram per cubic meter (kg/m3) |

| FOB Port | shenzhen, HK |

| Payment Terms | Letter of Credit (L/C), Western Union, Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA) |

| Supply Ability | 1000 Per Month |

| Delivery Time | 10-25 Days |

| Sample Available | Yes |

| Sample Policy | Sample costs shipping and taxes has to be paid by the buyer |

| Packaging Details | 25kg/bag |

| Main Export Market(s) | Middle East, Africa, South America, Asia |

| Main Domestic Market | All India |

| Certifications | ISO9001/ISO14001 |

Product Overview

Key Features

This product is a new type of high efficiency and high content of PE antifogging masterbatch. It can quickly migrate, anti-fogging effect work fast and efficiency lasting for up to 12 months. has excellent heat or cold fog resistant. Suitable for POF, CPE, IPE anti-fog film making. No smell, contact with food directly. Comply with the requirements of FDA, GB 9685 Hygienic standards for uses of additives in food containers and packaging materials.

Product features

Can be migrated quickly, Anti-fog effect work fast and lasting,

Physical index

1. Appearance: Translucent granules

2. Density: 0.89~0.93 g/cmA

3. Melt index: 5~10 g/10min(230a ,2.16kg)

4. Moisture content: a 2000 ppm

Product Application

Anti-fog agents are working gradually migrating from the film core to the surface.

Migration velocity is related to the environmental temperature and humidity during the film production and post-processing.

Joint 3 ~ 5% to the core layer of co-extrusion composite film. Also need to join appropriate amount at the anti-fog layer.

Dosage should be adjusted with different film thickness, season, anti-fogging effect requires.

1. Under the low temperature and low humidity environment. Please appropriate increase anti-fog masterbatch amount.

2. The film thinner, the more anti-fog masterbatch should be joined.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

50

Establishment

2010

Working Days

Monday To Saturday

Payment Mode

Telegraphic Transfer (T/T)

Certification

ISO9001, ISO14001

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Foshan, Guangdong

Mr Saffi

Address

Xingtan town, Foshan, Guangdong, 528325, China

additive masterbatches in Foshan

Report incorrect details