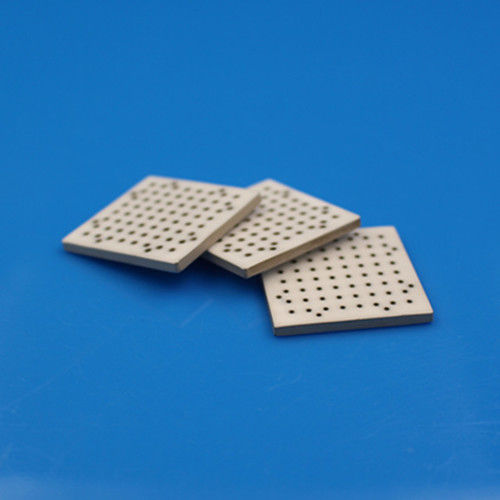

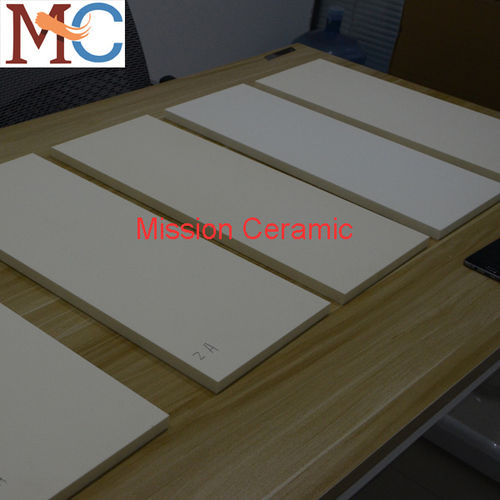

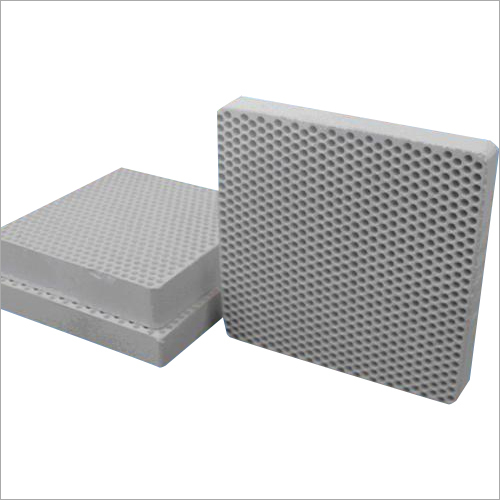

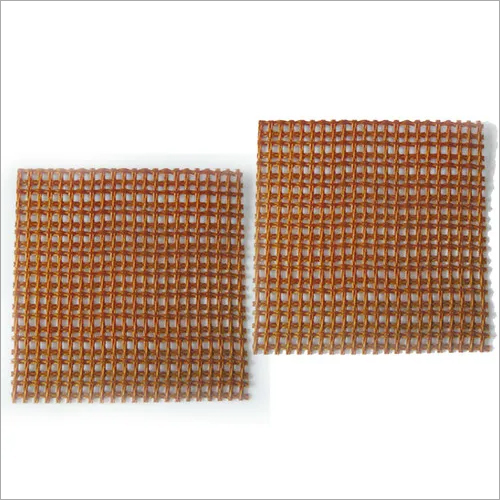

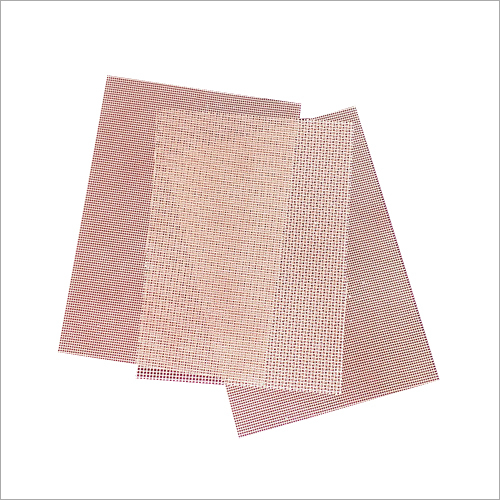

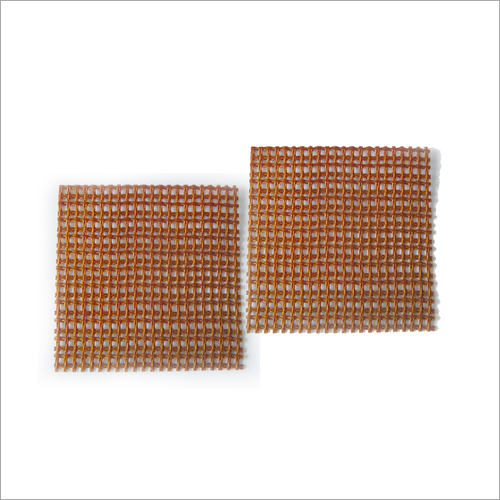

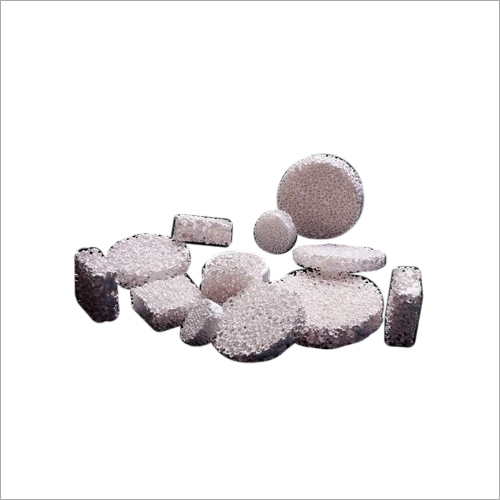

Alumina Ceramic Foam Filter - 50-600mm, White Color, 10-60ppi Pore Size, 80-90% Efficiency | High Porosity, Mechanical Stability, Excellent Thermal And Corrosion Resistance

Price: nan USD / Piece

Get Latest Price

Minimum Order Quantity :

500 Piece

Brand Name :

Sf

In Stock

Product Specifications

| Height | 11-50 Millimeter (mm) |

| Weight | 30-6000 Grams (g) |

| Size | 40-600 |

| Pore Size | 10-60ppi |

| Outlet Diameter | 40-600 Millimeter (mm) |

| Width | 40-600 Millimeter (mm) |

| Usage | Filter is installed in the filter bowl |

| Filter Rating | 2-45kg/s |

| Inlet Diameter | 40-600 Millimeter (mm) |

| Length | 40-600 Millimeter (mm) |

| Shape | Round ,square ,custom geometric shapes |

| Color | white |

| Filter Media | Polypropylene (PP) |

| Product Type | mass production |

| Pressure | 0.8 mpa |

| Material | Other |

| Type | Industrial Depth Filter Cartridge |

| Cartridge Style | Other |

| Diameter | 50-600 Millimeter (mm) |

| Efficiency | 80-90% |

| Application | filter for casting |

| Warranty | Three years |

| FOB Port | TIANJIN SHANGHANG ,CHINA |

| Payment Terms | Letter of Credit (L/C), Western Union, Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Delivery Point (DP), Days after Acceptance (DA) |

| Supply Ability | 400000 Per Year |

| Delivery Time | 10-15 Days |

| Sample Available | Yes |

| Sample Policy | Within a certain price range free samples are available |

| Packaging Details | carton and pallet |

| Main Export Market(s) | Western Europe, Australia, South America, Middle East, Africa, Central America, Asia, Eastern Europe, North America |

| Main Domestic Market | All India |

| Certifications | Alumina Foam Ceramic Filter Product description1.Increasing the uniformity of the internal structure of the metal2.Decontaminated the molten metal liquid3.Improvement of mechanical properties4.Elimination of metallurgical imperfections (gas sinks, porosity, leaks);5.Simplified gating systemTechnical Parameters:Ceramic foam filters of three-dimensional structure of various shapes (circle, oval, rectangle, square), sizes, thicknesses (12-50 mm) and porosity (8-60 ppi aEUR" pore per linear inch) are offered, depending on the needs and requests of customers.Dimension (A+- 3 mmaEUR"): 7x7in 9x9in 12x12in 15x15in 17x17in 20x20in 23x23in 26x26inThickness: 50 A+- 2 mmBevel Angle: 17.5A+- 1.5AdegSpecial Dimension: square, rectangular, round, trapezoidal, abnormal, or customized as per the requirement.Item Densityi1/4^g/cmA3i1/4%0 Rupture Modulusi1/4^816a,,f /Mpai1/4%0 Comprehensive Strengthi1/4^Mpai1/4%0 Operating Temperaturei1/4^a,,fi1/4%0 Sealing gasket expanding temperatureA i1/4^a,,fi1/4%0Index 0.45 5. 5 0. 8-1.0 1550 450-550Pore size for Ceramic Foam Filter:Pores amount in any 25.4mm length filterMesh Numberi1/4^PPIi1/4%0 10 20 30 40 50 60Pore Density(PCS) 8-12 18-22 28-32 38-42 48-52 58-62 |

Product Overview

Key Features

Company Details

Business Type

Exporter, Importer, Manufacturer, Supplier

Employee Count

300

Establishment

2013

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Certification

ISO 9001:2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Cangzhou, Hebei

Sales Manager

Ms Kerry

Address

Guanting Industrial Park, Cangzhou City, Hebei Province China, Cangzhou, Hebei, 061034, China

alumina ceramic plate in Cangzhou

Report incorrect details