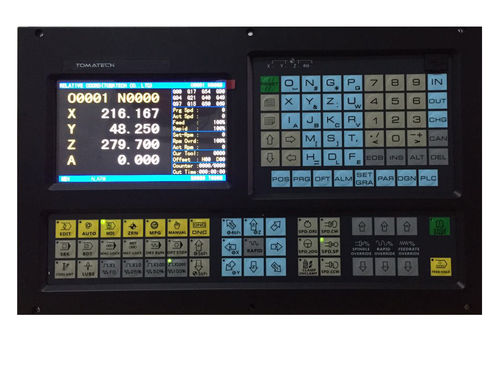

Metal 3 Axis Milling Controller 2000

Price:

Get Latest Price

In Stock

Product Specifications

| Color | Black |

| Size | Customised |

| Product Type | 3 Axis Milling Controller |

| Shape | Rectangular |

| Material | Metal |

| Payment Terms | Paypal, Others |

| Delivery Time | 7 Days |

| Main Domestic Market | All India |

Product Overview

Key Features

Three axes control; 3 axes linkage; 2 analog spindles

1ms interpolation cycle, 0.1I m control precision.

Two channels -10V ~ 10V analog voltage output, support double spindle control

Linear type, index type and S type etc. acceleration and deceleration types can be chosen.

Embedded with PLC programming, the current running PLC programming can be chosen

PLC displayed online, real time monitoring, signal real time tracing

Supports statement type macro programming, supports macro codes with parameters calls.

Flexible tapping and rigid tapping can be set by parameters

Includes spiral, scaling, polar coordinate, fixed circle

and a variety of slotting compound cycle function.

Includes historical alarm and resumen operation functions, ita s convenient for users to operate and maintenance.

Support multi-level passwords for equipment maintenance and management

36 point general input/36 point general output

Support standard RS232 and USB port, support U disk documents operation, system configuration and software

updated, it can meet the functions that documents transfer, serial ports DNC machining and USB online machining.

Control axis:

Control axis: 3 axis (X, Y, Z)

Linkage axis: 3 axis Feeding axis functions

Position command range:

Metric input (G21) -9999.9999mm ~9999.9999mm, the mininum command unit: 0.0001mm

Inch input (G20): -999.9999inch ~999.9999inch, the mininum command unit: 0.0001inch

Electronic gear ration: command multiplier 1 ~ 65536, command multiplier1 ~65536

Rapid traverse speed: maximum 60m/min

Rapid traverse override: F0, 25%, 50%, 100% four levels real-time tuning

Cutting feedrate: maximum feeding speed: maximum 15m/min (G94) or 500.00mm/r (G95)

Feedrate override: 0 ~ 150% sixteen-level real-time tuning

Manual feedrate: 0 ~ 150% sixteen-level real time tuning

MPG feeding: 0.001mm, 0.01mm, 0.1mm, 1mm four gears

Single step feeding: 0.001mm, 0.01mm, 0.1mm, 1mm four gears

Interpolation mode: linear interpolation, arc interpolation, spiral interpolation and ragid rapping

Automatic chamfering function

Acceleration/deceleration types:

Cutting feeding: before the acceleration and deceleration linear type, before the acceleration and deceleration S

type, after the acceleration and deceleration linear type and after the acceleration and deceleration index type.

Fast moving: before the acceleration and deceleration linear type, before the acceleration and deceleration S type,

after the acceleration and deceleration linear type and after the acceleration and deceleration index type.

System with preview function, it can read 15 NC programming, make small line interpolation in high speed and

smooth, ita s suit for components machine toolings processing.

The original speed of acceleration and deceleration, end speed and acceleration&deceleration speed set by

parameters.

Manual mode, handwheel mode is after acceleration and deceleration control, handwheel mode can choose

emergency mode or full operation mode.

Rapid positioning can choose linear or broken line.

Spindle axis functions:

Two channels -10V ~ 10V analog voltage output, support double spindle control

Spindle encoder: encoder lines can be set (100 p/r ~ 5000p/r)

Encoder and spindlea s transmission ratio: (1 ~ 255):(1 ~ 255)

Spindle ration: 50% ~ 120% eight stages real-time tunning in total

Spindle axis constant line speed control

Tapping circle, rigid tapping

Tool functions:

Tool length compensation

Tool point radius compensation (C type)

Precision compensation:

Thread pitch error compenstation: Compensation points, compensation interval, compensate original position can

be set.

Backlash compensation: can set reverse interval to interpolation machine tool by fixed frequency or lifting speed

mode.

Company Details

Business Type

Importer, Supplier, Trading Company

Employee Count

10

Establishment

2018

Working Days

Monday To Monday

GST NO

33GWRPS4793H1ZM

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 33GWRPS4793H1ZM

Chennai, Tamil Nadu

Proprietor

Mr Subha Kannaiyan

Address

Tambaram, Nelson Mandela Street, Near nsn School, Chennai, Tamil Nadu, 600064, India

cnc controller in Chennai

Report incorrect details