- Tradeindia

- Cranes

- Workstation Crane

Workstation Crane

(24 products)Monorail Crane Crane Traveling Speed: 20/1 M/M

MOQ1 Unit/Units

Crane Traveling Speed20/1 m/m

ConditionNew

SizeStandard

Workstation Crane Manufacturer Application: Construction

Price: 570000 INR/Piece

MOQ1 Piece/Pieces

ConditionNew

ColorYellow

Product TypeWorkstation Crane

Robust Machinery Solutions

Ahmedabad

Trusted Seller

Trusted Seller2 Years

Super Seller

Super SellerWorkstation Crane - Application: Industrial

Price: 2500000 INR/Unit

MOQ1 Unit/Units

Power SupplyElectric

FeatureHigh Quality

Crane Traveling Speed5 m/m

Industrial EOT Crane Work Services

Product DescriptionIndustrial EOT Crane Work Services

Workstation Jib Crane Application: Industrial

Price: 200000 INR/Piece

MOQ1 Piece/Pieces

UsageConstruction

Product TypeJib Crane

Power SupplyElectric

Workstation Cranes

Product DescriptionWe offer to our clients superior quality Workstation Cranes. Due to high quality and durability these Workstation Cranes are famous among its user. These products are available in market at most economical rates. Our products are highly appreciated by our clients in the market.\015\012

Workstation Crane By G. R. Cranes & Elevators

Product Description\015\012Workstation Cranes are mostly suitable for workstation bridge & jib cranes. These Workstation Cranes are offer to prestigious customers at most reasonable rates. Customers can avail these Workstation Cranes in different sizes and shapes. We ensure to satisfy the different requirements of cus

I Shape Workstation

Price Trend: 20000.00 - 200000.00 INR/Unit

MOQ1 Unit/Units

Supply Ability5 Per Week

Delivery Time5 Days

Main Domestic MarketAll India

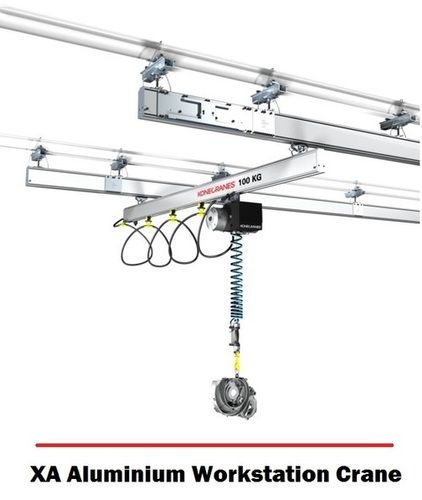

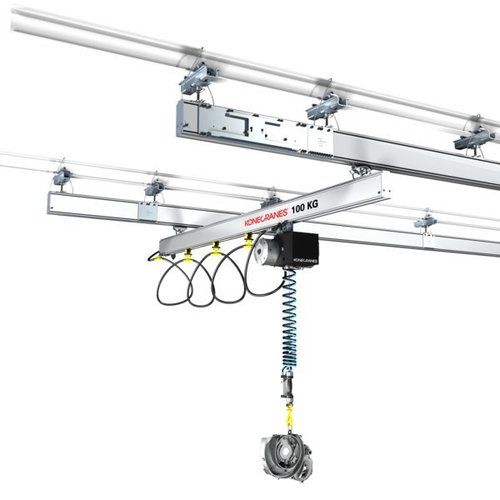

XA Aluminium Workstation Cranes

Product DescriptionWe "Konecranes" are among the most reputed firm indulged in manufacturing and supplying a huge gamut of XA Aluminium Workstation Cranes from Mumbai, Maharashtra, India. Our workstation crane is designed to meet the varied and demanding requirements of workstations and production lines that need up t

Aluminum Rail Workstation Crane

Product DescriptionBacked by our hard-earned experience of this industry, we are engaged in offering an exclusive array of Aluminum Rail Workstation Crane to our precious customers from Pune , Maharashtra , India. Offered this product is the light crane systems are designed for workstation and production lines. Our al

White Xa Aluminium Workstation Cranes

Product DescriptionWe are an accredited organization engaged in manufacturing and supplying our valued customers a huge range of XA Aluminium Workstation Cranes from Jejuri, Maharashtra, India. The offered workstation crane systems are designed to meet the varied and demanding requirements of workstations and producti

Top Rated Products

FAQs Related to Workstation Crane

Who are the top workstation crane manufacturers in India?

- Max Industries

- Ab & Co. Engineers

- Action Construction Equipment Ltd.

- A One Enterprise

- Malgudi Associates

- Neer Industries

- Robust Machinery Solutions

- Inovic Crm India Private Limited

- Meeka Machinery Pvt. Ltd.

- Cranoist Engineers

Which cities have the largest number of workstation crane suppliers?

- Pune

- Mumbai

- Bengaluru

- Hyderabad

- Ahmedabad

- Ludhiana

- Vadodara

- Sahibabad

- Howrah

- Jejuri

- Kapadwanj

What is the price range for workstation crane offered by listed companies?

| Company Name | Currency | Product Name | Price |

|---|---|---|---|

| ROBUST MACHINERY SOLUTIONS | INR | Workstation Crane Manufacturer | 570000 |

How many trusted sellers are available for workstation crane?

- MALGUDI ASSOCIATES

- ROBUST MACHINERY SOLUTIONS

- A ONE ENTERPRISE

- Neer Industries

- ACTION CONSTRUCTION EQUIPMENT LTD.

- MAX INDUSTRIES

- AB & CO. ENGINEERS

What is the minimum order quantity for workstation crane?

Do listed companies have registration & certifications?

- MALGUDI ASSOCIATES

- MAX INDUSTRIES

- LIFTBOY INDUSTRIES

- ROYAL ENTERPRISES

- ANKIT EQUIPMENTS (P) LIMITED

What is the get latest price feature?

What types of payment methods are accepted by the workstation crane suppliers?

XA Aluminium Workstation Cranes

Product DescriptionAs a pioneer business name, we are readily indulged in the business of manufacturing, exporting and supplying to our patrons an exclusive collection of XA Aluminium Workstation Cranes from Dusseldorf, Nordrhein-Westfalen, Germany. Our XA aluminium workstation crane applies the strength and low weigh

Action Construction Equipment Ltd.

Faridabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller9 Years

More details...

More details...

Ab & Co. Engineers

Bengaluru

Trusted Seller

Trusted Seller15 Years

Premium Seller

Premium SellerMore details...

More details...

More details...

More details...

Latest from Workstation Crane

Workstation Crane

By:

Neer Industries

Industrial Pillar Jib Crane

By:

Technical Enterprises

Chain Hoist Crane

By:

Konecranes Private Limited

Low Profile Rail System

By:

Beeyar Associates

XA Aluminium Workstation Cranes

By:

Gottwald Port Technology Gmbh

Aluminum Rail Workstation Crane

By:

United Crane Components Pvt. Ltd.

ATL Vertical Lifter

By:

Wmi Konecranes India Ltd.

Explore More Cities

Explore in hindi

कार्य केंद्र क्रेन

Workstation cranes are a type of bridge cranes or overhead traveling cranes that are used to lift and move light to moderate weighing loads within a work area. These cranes consist bridge or girders, hoisting trolley, rope and poles. Work station cranes are specially designed to meet the demands and requirements of workstations and production lines that need machine with 2000 kg of lifting capacity. These cranes can be ceiling mounted or freestanding on the floor, which can be operated electrically or manually. Manually operated work station cranes are propelled by the hydraulic pump system.

Different types workstation cranes are Free standing work station cranes, Wall mounted workstation jib cranes, Wall mounted workstation bridge cranes and Work station monorail cranes.

Prime Components :

Various components of a Workstation Crane are as follows:

End stop bumpers a These are mainly used for enclosing tracks to stop the movement of hoist trolley. End stop bumpers have rubber coating for increased impact resistance.

Festoon sections a These are bolted onto an end of a runway to allow stack up of cable/ hose trolleys.

Cable/Hose clamps a These are attached to one end of the runway ( festooning section) and one end of the bridge.

Cable/Hose Trolleys a These have four wheels, which ensure easy movement of loads.

Flat cable festooning system a These are used to manage cables and hoses which provide power or necessary gaseous/liquid media for moving cranes.

End trucks a These carry the bridge along the runways. End trucks guard against crabbing of the workstation bridge cranes.

Hoist trolleys a These have sets of wheel, which allows the horizontal movement of hoisted loads.

Track Options in Workstation Cranes :

Workstation cranes are also available with varied track options like:

Alu Track a These are enclosed tracks, which are made from aluminum. Alu-Tracks reduce the overall system weight, so that bridge cranes can be operated more smoothly.

Steel Tracks a These tracks are made from high quality stainless steel, which gives these tracks an extra strength and durability.

Trussed Steel Tracks a The trussed steel tracks are used for longer span in locations where repeated support points are not available.

Application areas :

These are widely used in various sectors and industries such as:

Automobile workshops

Food and beverage production units

Film and theaters

Flea markets

Textile industries

Aircraft manufacturing units

Client Testimonials & Reviews

RohitSachdeva

EARTH EQUIPMENTS

We are associated with Tradeindia.com since 1 year. Its a good B2B Platform to do business and for promotion on Google as well. I would look forward to be in long term relationship with this company.

Paresh Kareliya

GANESH ENGINEERING CO.

We are very thankful to Infocom Network Ltd. and its services to promote our product through Tradeindia.com on Internet. We get good support from their CRM and getting good Inquiries for Domestic as well internationally. We came to know of several portals but we choose Tradeindia.com for its services and different features we had been member since last 2 years and already subscribe for 2 more years in advance. from our Point of view we think Tradeindia.com is one of the best portals which we came to know from many years of experience of our business. We recommend Tradeindia.com as one of the best portal in online and off-line promotion for business activities. We wish Infocom Team and Specially their CRM Support Team for a great success in coming years and also wish that they will continue doing good work for long period.

Workstation Crane Price List

Product Name | Expected Price |

|---|---|

| Workstation Crane Manufacturer | 570000 |

This Data was Last Updated on 2024-12-15

Workstation Crane Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Max Industries Kapadwanj, India | 17 Years |

Ab & Co. Engineers Bengaluru, India | 15 Years |

Action Construction Equipment Ltd. Faridabad, India | 9 Years |

A One Enterprise Vadodara, India | 4 Years |

Malgudi Associates Pune, India | 3 Years |

Neer Industries Ahmedabad, India | 3 Years |

Robust Machinery Solutions Ahmedabad, India | 2 Years |

Inovic Crm India Private Limited Ahmedabad, India | 2 Years |

Meeka Machinery Pvt. Ltd. Ahmedabad, India | 1 Years |

Cranoist Engineers Ahmedabad, India | 1 Years |

Upcoming Tradeshows

Gulfood 2025

Mon, 17 Feb, 2025 - Fri, 21 Feb, 2025

National Expo Raipur 2025

Sun, 19 Jan, 2025 - Wed, 22 Jan, 2025

International Crop Science Conference and Exhibition 2025

Tue, 21 Jan, 2025 - Wed, 22 Jan, 2025

LogiMAT India 2025

Thu, 13 Feb, 2025 - Sat, 15 Feb, 2025

WATER EXPO VIJAYAWADA 2025

Wed, 29 Jan, 2025 - Fri, 31 Jan, 2025

Printing South China 2025

Tue, 04 Mar, 2025 - Thu, 06 Mar, 2025

CHINA INTERNATIONAL FURNITURE FAIR 2025

Tue, 18 Mar, 2025 - Fri, 21 Mar, 2025

INDIA ART FESTIVAL 2024

Thu, 19 Dec, 2024 - Sun, 22 Dec, 2024

MachAuto 2025

Fri, 23 May, 2025 - Mon, 26 May, 2025

10th IMTOS-India Machine Tools Show 2025

Thu, 15 May, 2025 - Sun, 18 May, 2025

Popular Categories