- Tradeindia

- Moulds

- Plastic Die Mould

Plastic Die Mould

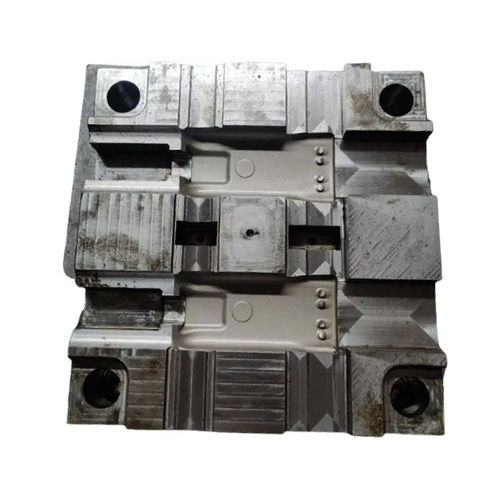

(719 products)Pcd Die Mold - Application: Industrial

Price: 650 INR/Piece

MOQ5 Piece/Pieces

ApplicationIndustrial

Product TypeDie Mould

MaterialSS

ComputerizedNo

Automatic GradeManual

Drive TypeManual

Shanghai Ehan-am Co., Ltd.

Shanghai

Trusted Seller

Trusted Seller Super Seller

Super Seller4 Years

Plastic Moulds - Color: White

Price: 125 INR/Unit

MOQ100 Unit/Units

ColorWhite

Product TypePlastic Moulds

Life Span3-5 yeats

SizeStandard

MaterialPlastic

Shaping ModePerform Mould

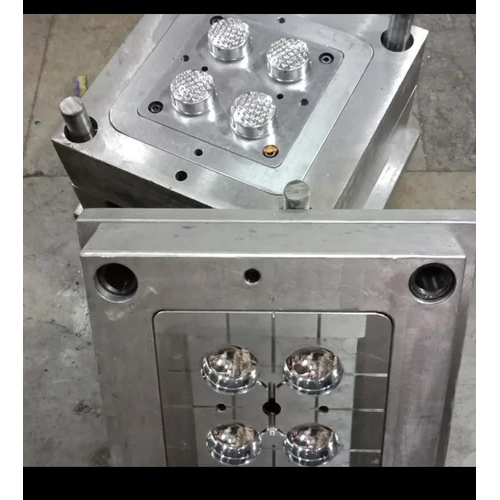

Industrial Grade Rust Proof Aluminum And Plastic Polish Finished Die Mould

Price: 30000 INR/Piece

MOQ1 Piece/Pieces

UsageIndustrial

Weight15 Kilograms (kg)

ColorSliver

Product TypeDie Mould

Length15 Inch (in)

Molding MaterialAluminium

Supreme Techno Plast Industries

Mumbai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller4 Years

View More

Plastic Drum Die Mould - Color: Silver

Price : 80000 INR

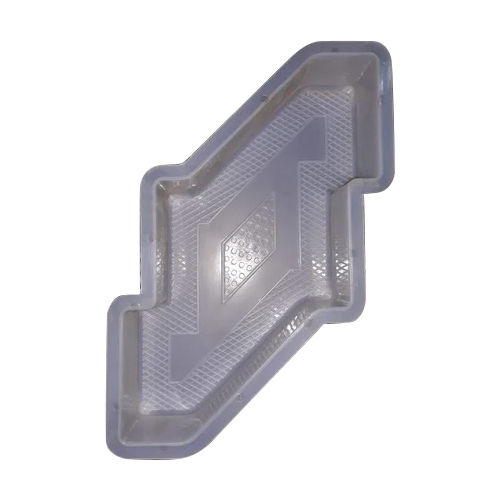

80Mm Plastic Zig Zag Mould - Cavity: Single Or Multiple

Price: 23 INR/Piece

MOQ100 Piece/Pieces

UsagePaver Block

Mold BaseStandard Plastic

ColorWhite

Molding MaterialPVC / Concrete / Cement mixture

Size80 mm Thickness

CavitySingle or Multiple

Plastic Mould - Steel, 4-6 Inch Size, Silver Color | Rugged Design, Easy Installation, Corrosion Proof

MOQ1 Piece/Pieces

Weight150 Kilograms (kg)

Product TypeMould

Size4-6 Inch

ColorSilver

MaterialSteel

View More

Gray Plastic Mold Die

Price : 50000 INR

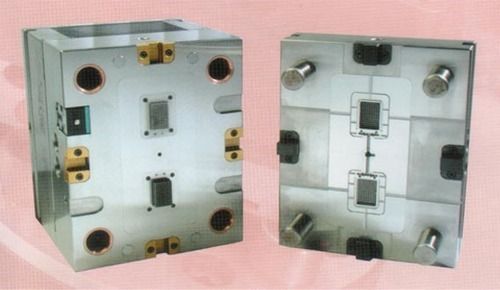

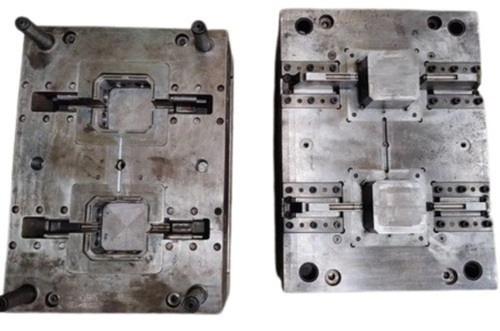

Moulding Dies - Material: Metal

Price: 50000.00 INR/Number

MOQ2 Number

UsageIndustrial

SizeStandard

Product Typemoulding dies

MaterialMetal

Shaping ModeDie Casting

Warranty1 Year

View More

Plastic Die Mould - Color: Silver

Price : 39989 INR

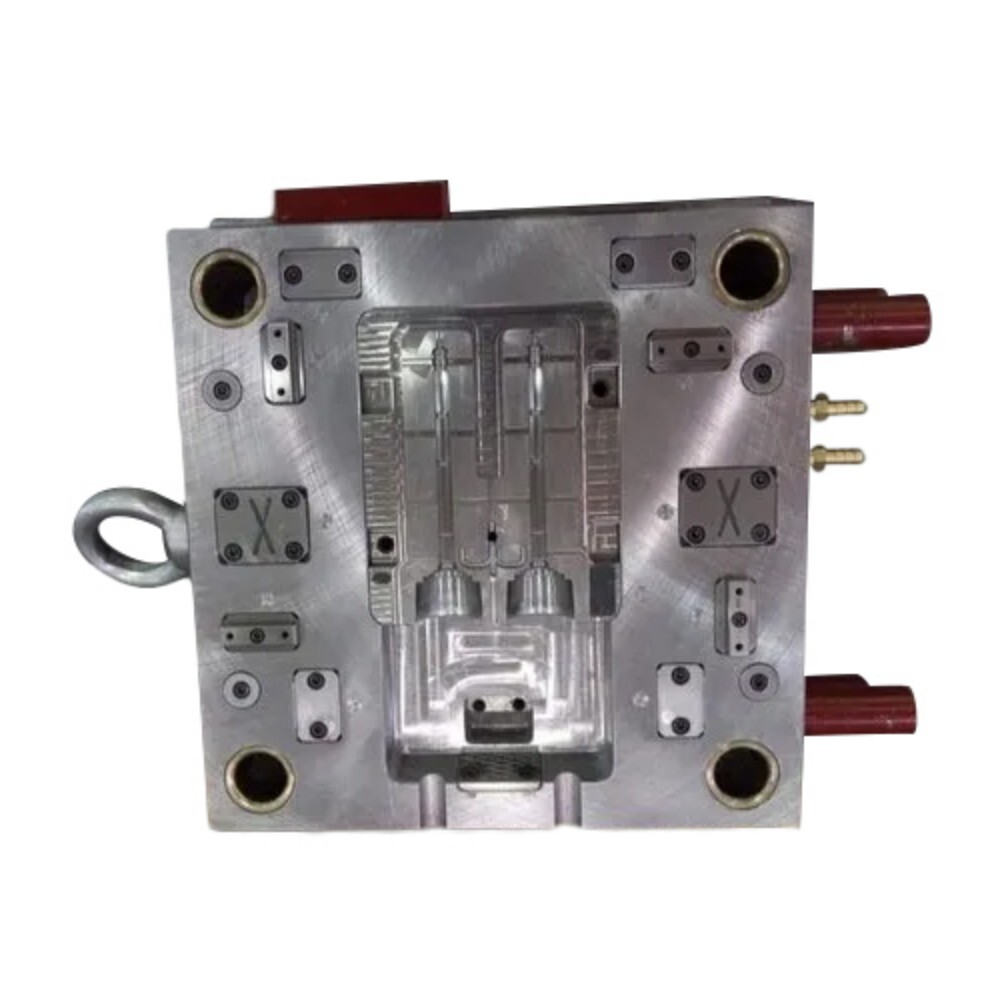

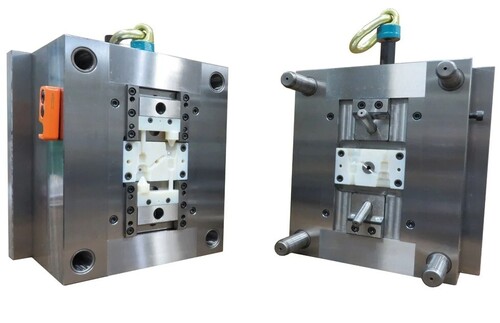

Plastic Injection Molding Die - Color: Silver

Price: 1500 USD ($)/Unit

MOQ1 Unit/Units

TypeInjection Molding Die

MaterialMild Steel

Shaping ModeSquare

Surface TreatmentPolishing

SizeDifferent Size

ColorSilver

Dongguan Yeeshine Technology Co., Limited

Dongguan

Trusted Seller

Trusted Seller2 Years

View More

Custom Design Moulding Plastic Molding Die Mould Injection Products

Price : 3 USD ($)

Die High Precision Plastic Injection Mould - Color: Silver

Price : 1500 USD ($)

Plastic Injection Die And Mould - Application: Industrial

Price: 200000.0 INR/Unit

MOQ1 Unit/Units

ColorSilver

Surface TreatmentPolished

ApplicationIndustrial

FeatureHigh Quality

MaterialMetal

WarrantyYes

Plastic Die Mould - Metal, Different Sizes Available, Silver Color | Horizontal Mechanical Clamping, Boxed Square Packaging

MOQ1 Unit/Units

Product TypePlastic Die Mould

UsageIndustrial

SizeDifferent Available

ColorSilver

MaterialMetal

WarrantyYes

Semi Automatic Die Mould

MaterialP20-EN31

DimensionsAs per design

PrecisionAs per requirement

RunnerAs per design

GradeSemi-automatic

OriginMade in India

Drishti Polymers

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller18 Years

View More

Plastic Die Mould - Color: Silver

Price : 10000 INR

Plastic Part Die And Mould - Color: Silver

Price : 10000 INR

Plastic Moulding Die - Color: Silver

Price: 100000 INR/Piece

MOQ1 Piece/Pieces

ColorSilver

Product TypePlastic Moulding Die

SizeStandard

UsageIndustrial

MaterialOther

Plastic Molded Membrane Body Cap - Plastic Material, White Color | Industrial Use in Versatile Plastic Injection Moulding Solutions

Price: 100 INR/Piece

MOQ10000 Piece/Pieces

UsageIndustrial

ColorWhite

Product TypeMembrane Body Cap

Top Rated Products

FAQs Related to Plastic Die Mould

Aerospace Plastic Moulding Die - Color: Grey

Price: 300000.00 INR/Unit

MOQ1 Unit/Units

Size40x300 ( WxH )

Weight10 Kilograms (kg)

ColorGrey

UsageUsed For Aerospace Prototypes

MaterialOther

WarrantyYes

View More

Gas Cylinder Safety Plastic Cap Mould Die - Color: Silver

Price : 350000 INR

Plastic Container Mould Die - Color: Silver

Price : 150000.00 INR

Plastic Disposable Glass Mould Die - Color: Silver

Price : 200000 INR

Plastic Bottle Moulding Die - Color: Silver

Price : 50000.00 INR

Plastic Token Mould Usage: Industrial

MOQ500000 Piece/Pieces

UsageIndustrial

Shaping ModeBlowing Mould

MaterialPlastic

Plastic Chair Moulding Die - Color: Silver

Price: 300000 INR/Unit

MOQ1 Unit/Units

Molding MaterialHDPE

SizeDifferent Size

ColorSilver

Product TypeMoulding Die

UsageIndustrial

Shaping ModeInjection Mould

Ggfjs Engg Products

Faridabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Metal Tail Light Moulds

UsageFor Automobile's accessory making industry

Product TypeTail Light Moulds

MaterialMetal

Household Moulds Density: 100

MaterialSteel

DimensionsVariable

Cavity count2

Surface finishHigh Polish

Hardness60 HRC

WeightVariable

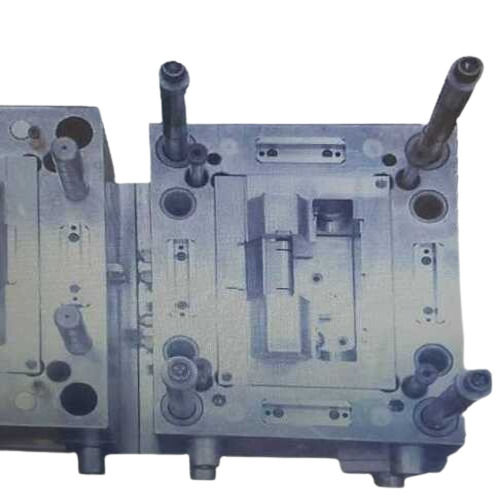

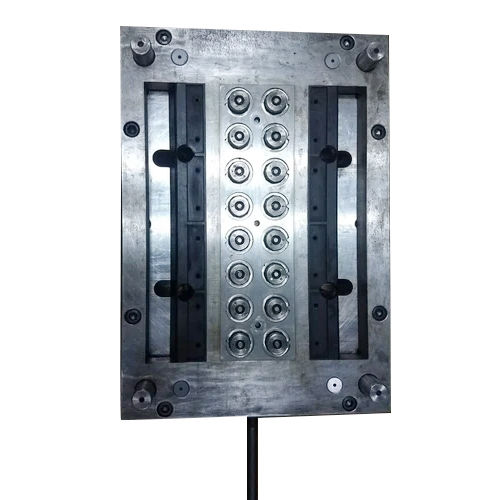

Plastic Injection Molding Die - Material: Steel

Price: 300000 INR/Unit

MOQ1 Unit/Units

Working ProcessPunching

UsageIndustrial

Size13x8 inch(LxW)

MaterialSteel

Shaping ModeDie Casting

Warranty1-2 Years

Sliver Plastic Injection Mould

Price: 100000 INR/Piece

MOQ1 Piece/Pieces

TypePlastic Injection Mould

MaterialSTEEL

Plastic MaterialPC

Working Temperature300 Celsius (oC)

Surface TreatmentPolishing

Size800-500-500

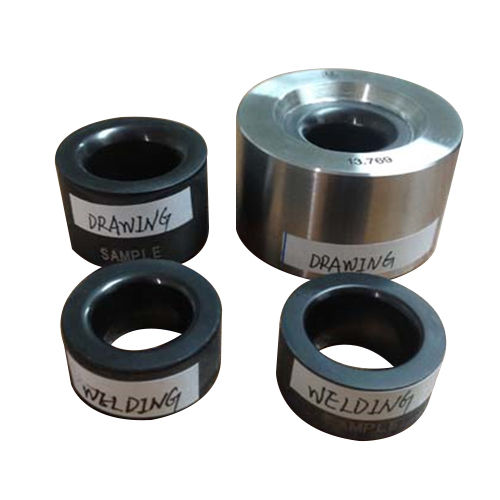

Industrial Die And Mould - Metal Material, Different Sizes Available | Suitable for Punching, Welding, and Extrusion Moulding Applications

Price: 100 INR/Piece

MOQ50 Piece/Pieces

SizeDifferent Sizes Available

UsageIndustrial

Working ProcessPunching, Welding

MaterialMetal

Shaping ModeExtrusion Mould

Precision Plastic Injection Moulding Die - Color: Silver

Price: 220000.0 INR/Unit

MOQ1 Number

ColorSilver

TypePrecision Plastic Injection Moulding Die

MaterialSS

Surface TreatmentPolishing

WarrantyYes

View More

Seal Cap Moulding Die - Color: Silver

Price : 25000.0 INR

Tic Tac Injection Moulding Die - Color: Silver

Price : 550000.0 INR

Plastic Injection Moulding Die - Metal, Silver Finish | Premium Quality, Industrial Application, Warranty Included

Price: 70000 INR/Unit

MOQ100 Unit/Units

ColorSIlver

ApplicationIndustrial

TypePlastic Injection Moulding Die

MaterialMetal

WarrantyYes

View More

Low Cost Plastic Mould Dies

Get Best Deal

Cost-effective Plastic Mould Dies

Get Best Deal

Plastic Mould Dies

Get Best Deal

Silver Rubber Mould Die

Price : 70000 INR

Strong Plastic Die Mould

FeaturesHigh Precision, Durable Build, Customizable Design, Efficient Cooling, Easy Maintenance

Rubber Mould Die - Color: Sliver

Price: 10000 INR/Piece

MOQ1 , Piece/Pieces

ColorSliver

UsageIndustrial

Product TypeRubber Mould Die

MaterialAluminum

Warranty1 Years

Plastic Die Mould - Premium Grade Mild Steel, Up To 150 Kg Weight, Polished Finish | Silver Color, Semi-Automatic Usage in Plastic Moulding

Price: 100000 INR/Piece

MOQ1 Piece/Pieces

Colorsilver

UsageIndustrial

View More

Industrial Plastic Die Mould - Material: Ceramic

Price : 70000 INR

Die Moulding Plastic Pins - Plastic Material, Customized Size | Durable Mold Pins for Prolonged Service Life, Low Maintenance, Fine Finish

Price: 50 INR/Piece

MOQ50 , Piece/Pieces

SizeCustomized

Product TypeDie Moulding Plastic Pins

MaterialPlastic

ApplicationPress Tools, Dies, Industrial

Mild Steel Mobile Cover Injection Die Mould - Life Span: Long Life

Price: 200000 INR/Unit

MOQ1 Unit/Units

Life SpanLong Life

Working ProcessPunching

Size18X22 inch

UsageIndustrial

MaterialSteel

Shaping ModeExtrusion Mould

View More

Plastic Curtain Clip Die Mould - Material: Steel

Price : 50000 INR

Plastic Zigzag Mould - High-Quality Plastic, Various Sizes Available, Color As Per Availability - Extrusion Mould for Decorative Edgings, Trims, Borders

MaterialMild Steel

Capacity1 Ton

FinishingPolishing

Chain Blocks2

Standard Lift3 M

GearsSpur

Latest from Plastic Die Mould

Popular Plastic Die Mould

Introduction to Plastic Die Moulds

Non-metallic, synthetically produced materials are called plastics. For commercial use, they can be moulded into many different shapes and hardened. Products made from plastic moulding are widely available. Jars, safety caps, plastic tubes, handles, toys, bottles, cases, accessories, kitchen utensils and many other items are examples.

Even the keyboard and mouse you use are made of plastic through the moulding process. Even the plastic components of the chair you are sitting in are made using this process.

The basic principle of plastic moulding is to pour molten liquid plastic into a ready-made mould, such as a bottle mould. Once it has cooled, the mould is removed to expose the plastic bottle.

Types of Mouldings

Extrusion Moulding

Extrusion moulding involves forcing hot, molten plastic through a pre-formed hole to produce a long, shaped plastic object. A die is the flexible shape through which the molten plastic is forced. This die is specifically designed to produce the desired result. Making moulded biscuits is almost like running dough through a press.

Extrusion is also used in other types of plastic moulding to get the raw liquid into the moulds, but instead of using moulds to create the desired shape, extrusion uses the shape of the die to create the shape.

Compression Moulding

This technique involves pouring raw liquid plastic into a heated mould, which is then crushed to create the desired shape. The high temperature throughout the process ensures good strength in the finished product. The liquid plastic is cooled to maintain its shape before being trimmed and removed from the mould to complete the process.

Blow Moulding

The hollow and thin-walled bespoke plastic parts produced by blow moulding are hollow. This method is ideal when the plastic part needs to have a uniform wall thickness. Glass blowing is very similar to this process.

The machine melts the raw plastic until it becomes liquid and then inflates it like a balloon by blowing air into it. After being blown into a mould with a specific shape, the plastic begins to take on that shape as it grows and presses against the walls of the mould. The liquid balloon is cooled to maintain its shape after filling the mould. In a 12-hour working day, the process can produce up to 1400 pieces.

Using Injection Moulds

Extrusion and injection moulding are similar processes. Injection moulding is different because molten plastic is pumped directly into a unique mould. High pressure is used during injection to fill the mould and create solid parts. The plastic is cooled to maintain its new shape once the mould is filled, similar to the previous processes, and the mould is then opened.

This is similar to a jelly mould where the final product is created by filling and cooling the mould.

Movement in Rotation

In this process, sometimes called rotomoulding, the resin or liquid is poured into the mould and then rapidly rotated. The liquid is then evenly distributed over the entire surface of the mould to create a cavity with uniformly thick walls. The liquid plastic is removed from the mould after it has cooled and taken its new shape.

This process is cheaper and more environmentally friendly because it uses a small amount of material efficiently and produces very little waste.

Benefits of Using Plastic Die Moulds

1. Effective high output

Once the moulds are created, the process is incredibly fast, with cycle times as low as 10 seconds. Depending on the moulds you choose, it is suitable for medium and high volume production runs from 10,000 to well over 100,000 parts.

Occasionally, the use of a multi-cavity or family mould, which produces many parts from a single press, can help to increase productivity.

Consider an efficient front-end design and ordering process when outsourcing your tooling; take a look at our on-demand production.

2. Reasonable component costs

The cost per part for high volume production is quite reasonable. By using aluminium moulds instead of steel moulds, you can save costs even for medium volumes, i.e. between 10,000 and 25,000 parts.

3. Repetition

Multiple copies of the same product can be produced. If you need parts with tight tolerances and high reliability, this is the best option.

4. Wide range of materials

You can choose from a wide range of plastic materials depending on the properties you require from your end product. Protolabs also offers liquid silicone rubber moulding, so you are not restricted to using plastic.

A wide range of colours are available and you can even incorporate fillers into the moulding process to make the finished item more robust. Talk to us about what you need your part to achieve; there are usually a variety of options.

Plastic Die Mould Manufacturing Process

Blow moulding- Best suited for hollow objects

Suitable for hollow products such as bottles, blow moulds, the process follows the basic steps of glass blowing. Air is used to inflate a parison, a heated mass of plastic, often a tube. To create the desired shape, the air forces the plastic against the mould. After cooling, the plastic is ejected.

Blow moulding is used to make hollow, one-piece, large volume items. It is ideal if you need to produce a large number of bottles. Blow moulding produces very consistent, thin-walled containers. It can also be very cost effective.

Compression molding- suited for larger objects

Larger things, such as car parts, are best suited to compression moulding.

The name of this moulding technique says it all. A heated piece of plastic is pressed into shape using a heated mould. Plastic can be bought in bulk, but it often comes in sheets. The finished item retains its integrity thanks to the heating process, known as curing. The item is then removed from the mould after moulding, as with other moulding techniques. If plastic sheeting is used, the plastic must first be cut to size in the mould before the part can be removed.

Extrusion molding- suited for long hollow formed applications

Larger things, such as car parts, are best suited to compression moulding.

The name of this moulding technique says it all. A heated piece of plastic is pressed into shape using a heated mould. Plastic can be bought in bulk, but it often comes in sheets. The finished item retains its integrity thanks to the heating process, known as curing. The item is then removed from the mould after moulding, as with other moulding techniques. If plastic sheeting is used, the plastic must first be cut to size in the mould before the part can be removed.

How to Choose the Right Plastic Die Mould

- Hardness: The resistance of a material to compression and indentation is a measure of its hardness. Shore hardness, which can be divided into Type A and Type D, is measured using an indenter. Each category has a scale from 0 to 100 to better gauge the hardness of the material in question, with Shore A referring to softer plastics and Shore D referring to tougher plastics.

- Cost considerations: When deciding which material to use for your injection moulding project, cost is a key consideration. This choice requires careful consideration, as it also needs to take into account how the product will be used. Choosing a more expensive material up front can pay off in the long run, whereas cheaper solutions can sometimes lead to costly failures later on.

- Weight: The fourth and final factor to consider when selecting an injection moulding material is weight. This is because both the weight of the finished product and the weight of the moulded part depend on the density of the polymer. Weight can be a critical issue because lightweight consumer products often contain injection moulded parts.

Client Testimonials & Reviews

AshokSharma

DS EPS MACHINERY

We had a membership of tradeindia since 6 years. It is a largest B2B market place. We are fully satisfied customer of tradeindia. They provide a good business. I suggest all manufacturers to join with tradeindia.

NitinKumar

MYRAVYA ENGINEERING INDIA PVT. LTD.

We are associate with Tradeindia.com from last 4 Years and we are getting very good response from your company. Its very useful to increase our business.

RajeshPrajapati

R. K. HYDRAULICS

We are associated with tradeindia from 2014 and this platform helped us to improve and grow our Business, Branding and Promotion. I am getting good inquires and I expect the same in the future. Thanks to tradeindia.com.

Plastic Die Mould Price List

Product Name | Expected Price |

|---|---|

| 80Mm Plastic Zig Zag Mould | 23 |

| Plastic Die Mould | 120000 |

| Bottle Mould | 20000 |

| Cooler Back Frame Making Plastic Die Mould | 400000 |

| Dust Pan Making Plastic Die Mould | 105000 |

| 80mm Plastic Zig Zag Mould | 23 |

| Plastic Die Mould | 175000 |

| Plastic Cube Moulds | 550 |

| Plastic Storage Moulding Die | 50000 |

| Plastic Die Moulding | 25000 |

This Data was Last Updated on 2025-09-05

Plastic Die Mould Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Drishti Polymers Ahmedabad, India | 18 Years |

R. P. Enterprises Noida, India | 18 Years |

Royal Tile Machines New Delhi, India | 15 Years |

G. M. Industries New Delhi, India | 12 Years |

Ramatek Engineers Gurugram, India | 11 Years |

Shyamji Engineering Works Delhi, India | 7 Years |

Kamal Mould Ahmedabad, India | 6 Years |

G.t.s Engineering Works Delhi, India | 6 Years |

Niimbus Technocrats Ahmedabad, India | 5 Years |

M.s.enterprises Faridabad, India | 5 Years |

Upcoming Tradeshows

ENGIMACH 2025

Wed, 03 Dec, 2025 - Sun, 07 Dec, 2025

China (Guzhen) International Lighting Fair 2025

Wed, 22 Oct, 2025 - Sat, 25 Oct, 2025

8th INTERNATIONAL SOAP & DETERGENT EXPO 2026

Thu, 26 Feb, 2026 - Fri, 27 Feb, 2026

YARNEX - Mumbai 2025

Thu, 27 Nov, 2025 - Sat, 29 Nov, 2025

Spectra Expo 2026

Thu, 05 Feb, 2026 - Sat, 07 Feb, 2026

INDIA GREEN ENERGY EXPO 2026

Wed, 29 Jul, 2026 - Fri, 31 Jul, 2026

Indian Ceramics Asia 2026

Wed, 28 Jan, 2026 - Fri, 30 Jan, 2026

PharmaTech Expo & LabTech Expo 2026

Fri, 19 Dec, 2025 - Sun, 21 Dec, 2025

Pune Expo 2025

Wed, 10 Dec, 2025 - Fri, 12 Dec, 2025

ET TECH X 2025

Thu, 11 Dec, 2025 - Sat, 13 Dec, 2025

Popular Categories