- Tradeindia

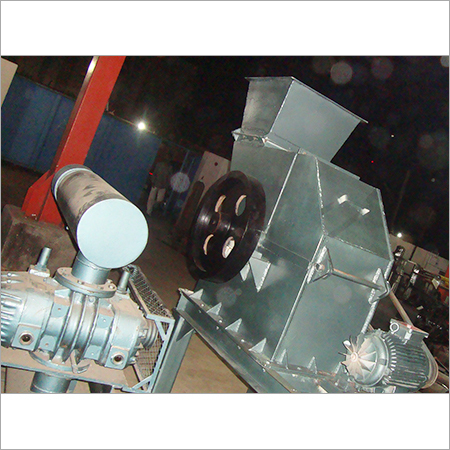

- Shredding Machine

- Glass Crushers

Glass Crushers

(56 products)Glass Shredder - Application: Industrial

MOQ1 Unit/Units

ApplicationIndustrial

Automatic GradeAutomatic

Frequency50 Hertz (HZ)

Warranty1 Year

SizeStandard

ColorWhite Blue

View More

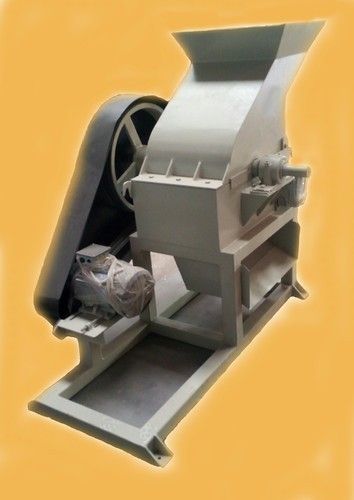

Glass Bottle Crusher Machine - Application: Industrial

Price : 250000 INR

Glass Bottle Crusher Machine - Application: Industrial

Price: 250000 INR/Piece

MOQ1 Piece/Pieces

Frequency50 Hertz (HZ)

SizeStandard

ColorBlue

ApplicationIndustrial

Voltage380 Volt (v)

Warranty1 Year

Amey Shredtech Private Limited

Thane

Trusted Seller

Trusted Seller Super Premium

Super Premium18 Years

Super Premium

Super PremiumGlass Crusher Incinerator - 800 Bottles Per Hour Capacity, 400 Liters Daily Service Tank | Includes Automatic Burner, Flue Gas Duct, and Motor Control Center

Voltage400V

Phase3-phase

Capacity800 bottles/hour

Dimensions700x660x400 mm

Fuel typeLight diesel

MaterialStainless steel

View More

Glass Crusher By Edutek Instrumentation

Get Best Deal

Glass Crushers - Steel Construction, Blue Color | 1-Year Warranty, Non-Computerized Design

MOQ1 Piece/Pieces

Product TypeGlass Crushers

General UseConstruction

MaterialSteel

ComputerizedNo

ColorBlue

Warranty1 Year

Glass Crusher - Color: Black

SizeStandard

ColorBlack, Silver, Blue

UsageIndustrial

Equipment TypeGlass Crusher

ConditionNew

MaterialSS

Aesha Conveyors And Crushing Equipment

Ahmedabad

Trusted Seller

Trusted Seller21 Years

View More

Low Maintenance Glass Crusher

Get Best Deal

Glass Crusher Plant - Automatic Grade: Automatic

Price : 900000 INR

Glass Crushing Plant

Get Best Deal

Stainless Steel Glass Bottle Crusher - Dual Shaft Shredding Machine, 100-500 Kgs/Hr Capacity, Fully Automatic Operation for Efficient Recycling

Price: 300000 INR/Unit

MOQ1 Unit/Units

FOB PortMumbai

Payment TermsCash in Advance (CID)

Supply Ability10 Per Month

View More

Stainless Steel Glass Bottle Crusher With 500 kg/hr Capacity

Price : 300000 INR

Glass Bottle Crusher

Product TypeBottle Crusher

Primary ColorGray

MaterialSteel, Plastic

Dimensions400x500x800 mm

Crushing Capacity50 bottles/hr

Power1.5 kW

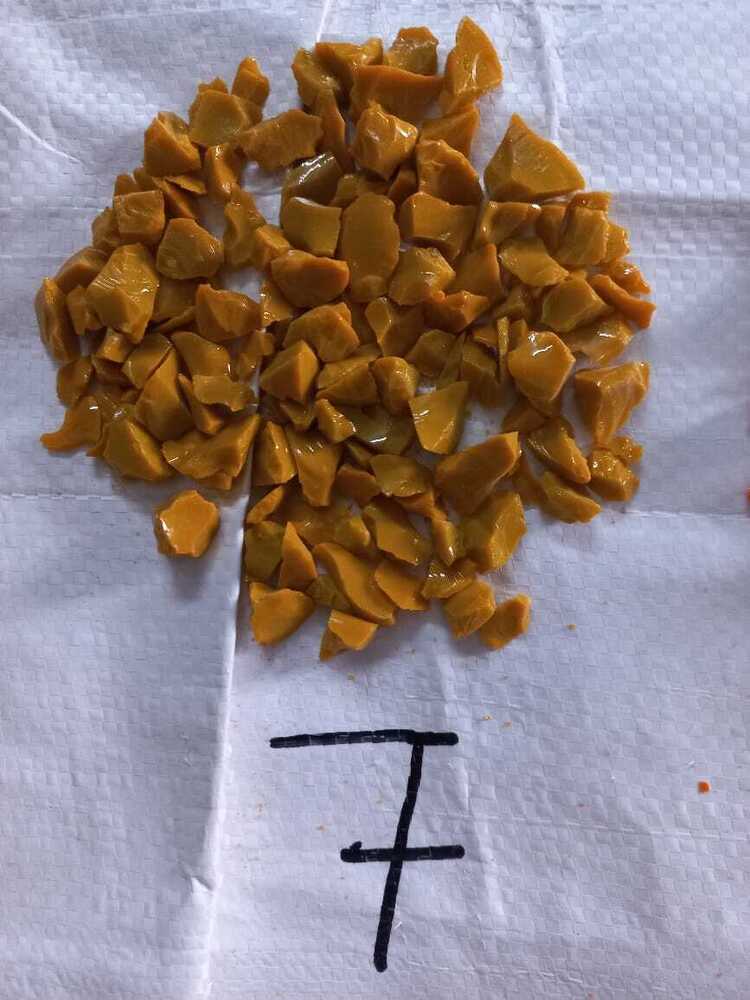

Recycled Royal Black Crushed Glass Chips For Terrazzo Floor Size: Size: (1) 1- 1.5 Mm (2) 2-3 Mm (3) 3-4 Mm (4) 4-5 Mm

Price: 375 USD ($)/Ton

MOQ1 Ton/Tons

Stone FormCut-To-Size

SizeSize: (1) 1- 1.5 mm (2) 2-3 mm (3) 3-4 mm (4) 4-5 mm

Marble TypeOther

Surface FinishingPolished

ColorBlack

View More

Red Jasper Crushed Agate Machine Polish Aggregate Chips For Sale And Wholsale Export Price In Ind Crystallized Glass Stone

Price : 110 USD ($)

Crushed Clear Glass Chips Transparent Made Of Recycled Glass For Fire Pits And Garden Decorations - Product Type: Natural Stone

Price : 400 USD ($)

Royal Blue Waste Stone Glass Crushed Chips And Aggregate For Glass Industries - Size: Size: (1)1- 1.5Mm (2) 2-3 Mm (3) 3-4 Mm (4) 4-5 Mm

Price : 350 USD ($)

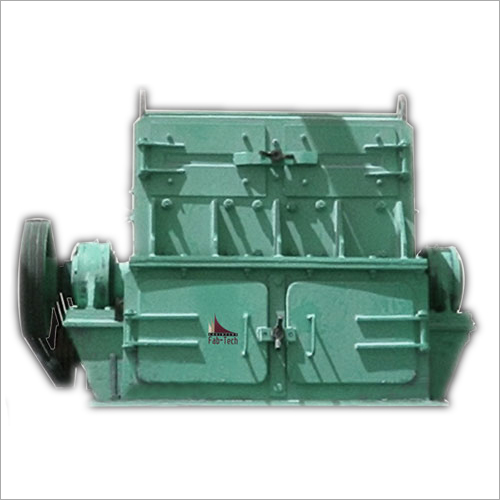

Glass Crusher By D. P. Pulveriser Industries

Product TypeGlass Crusher

General UseGlass recycling and waste management

MaterialOther, Metal (Steel)

TypeOther, Crusher

ComputerizedNo

AutomaticNo

Red Glass Cullet Crusher Machine

Price: 2,80,000 INR/Piece

MOQ1 Piece/Pieces

ColorRed

Product TypeGlass Cullet Crusher Machine

General UseCrusher Machine

MaterialSteel

ComputerizedYes

AutomaticYes

Heavy Duty Glass Bottle Shredding Machine

Body MaterialMild Steel

ApplicationIndustrial

Country of OriginIndia

Phase3 Phase

Voltage380-480V

Frequency50Hz

Blue Pre - Crusher

Price Trend: 42000 - 300000 INR/Unit

MOQ1 Unit/Units

Product TypeCrushing And Pulverizer, Other

Power SourceElectricity

ColorBlue

View More

White Glass Crusher

Price : 12000 - 300000 INR

Top Rated Products

Glass Crushers - Steel Construction, Blue Color | 1-Year Warranty, Non-Computerized Design

Proton Construction Machinery

FAQs Related to Glass Crushers

Who are the top glass crushers manufacturers in India?

- D. P. Pulveriser Industries

- Aesha Conveyors And Crushing Equipment

- Miracle Marble Art

- Amey Shredtech Private Limited

- Micro Teknik

- Edutek Instrumentation

- Proton Construction Machinery

- Raj Electricals

- Industrial Engineers

- Shredall Private Limited

Which cities have the largest number of glass crushers suppliers?

- Mumbai

- Delhi

- Pune

- Bengaluru

- Coimbatore

- Ahmedabad

- Rajkot

- Vadodara

- Ludhiana

- Dombivli

- Gurugram

- Tiruchirappalli

- Anand

- Raichur

- Zhangjiagang

- Gavi

What is the price range for glass crushers offered by listed companies?

| Company Name | Currency | Product Name | Price |

|---|---|---|---|

| SHREDALL PRIVATE LIMITED | INR | Stainless Steel Glass Bottle Crusher | 300000 |

| Shree Shantinath Engineers | INR | Glass Crushers | 100000 |

| COGELME S.A.S. | INR | Industrial Glass Bottle Shredder Machine | 500000 |

| Monax Marketing | INR | Three Phase Automatic Glass Bottle Shredding Machine | 160000 |

| Pixel Systems | INR | Glass Bottle Shredding Machine | 125000 |

| SMS HYDROTECH | INR | Industrial Glass Bottle Shredder Machine | 250000 |

| Avanti Business Machines Limited | INR | Heavy Duty Glass Bottle Shredding Machine | 120000 |

| Dolphin Corporation Pvt. Ltd. | INR | Electrically Operated Glass Bottle Shredder Machine | 500000 |

| Prizm Enterprises | INR | Electrically Operated Glass Bottle Shredder Machine | 240000 |

| R.K. ENTERPRISES | INR | Heavy Duty Single Phase Glass Crusher Machine | 90000 |

How many trusted sellers are available for glass crushers?

- AMEY SHREDTECH PRIVATE LIMITED

- MICRO TEKNIK

- EDUTEK INSTRUMENTATION

- AESHA CONVEYORS and CRUSHING EQUIPMENT

What is the minimum order quantity for glass crushers?

Do listed companies have registration & certifications?

- MICRO TEKNIK

- EDUTEK INSTRUMENTATION

- PROTON CONSTRUCTION MACHINERY

- AESHA CONVEYORS and CRUSHING EQUIPMENT

- Pals & Company

- SMS HYDROTECH

- JAIN LABORATORY INSTRUMENTS PRIVATE LIMITED

- Guangzhou Siedon Technology Co., Ltd.

What is the get latest price feature?

What types of payment methods are accepted by the glass crushers suppliers?

Floor Mounted High Efficiency Electrical Automatic Heavy-Duty Glass Crushers

MaterialSteel

DimensionsCustomized

PowerElectrical

EfficiencyHigh

GradeAutomatic

InstallationFloor

Heavy Duty Automatic Glass Bottle Shredding Machine - Mild Steel, 3 Phase, 380 V - 480 V, 50 Hz, 1000 - 30000 Kgs Per Day Capacity | Electric Power Source, 1 Year Warranty, Coated Surface Treatment, Automatic Operation for Efficient Glass Recycling

Price: 125000 INR/Unit

MOQ1 Unit/Units

ApplicationIndustrial

ColorGreen

Voltage220 Volt (v)

Frequency50 Hertz (HZ)

SizeStandard

Control SystemAutomatic

Industrial Glass Bottle Shredder Machine

Price: 250000 INR/Unit

MOQ1 Unit/Units

Voltage440 Volt (v)

Control SystemSemi Automatic

ColorBlack

Frequency50 Hertz (HZ)

SizeStandard

Automatic GradeSemi

Crusher Sheeder Combo

ModelCrusher/Cutter

Capacity1500 Kg/Hr

Power15 Hp (1440 Rpm)

Input Size25Mm To 50Mm

Input Length300Mm To 2000Mm

MaterialSteel

Glass Crusher By Jain Laboratory Instruments Private Limited

materialSteel frame

power_supply220V

crushing_capacity50 kg/hr

motor_power1.5 HP

blade_materialHardened steel

hopper_size30 liters

View More

Glass Crusher Incinerator

Get Best Deal

Glass Crushers - Metal, Automatic Control System | Energy Saving, Lower Noise, High Torque, Easy Operation, Small Footprint

Price: 85000 INR/Piece

MOQ1 Piece/Pieces

MaterialMetal

Control SystemManually

WarrantyYes

Automatic GradeAutomatic

Glass Bottle Crushers Cut Size: All Sizes

MOQ1 units Unit/Units

UseMaize Straw Crusher

Sheet CapacityFind all sizes and custom

Cutter TypeTwo Shaft Cutter

Cut SizeAll Sizes

View More

Glass Shredder Machine

Get Best Deal

Glass Bottle Crushing Machine Large & Customizable

Get Best Deal

Glass Bottle Crushers

Get Best Deal

Automatic Glass Shredder Crusher Machine - Mild Steel, 3 Phase, 380 V - 480 V, 1000 - 30000 Kgs Per Day Capacity | Electric Power, Coated Surface Treatment, 1 Year Warranty

Body materialMild steel

Voltage380-480V

Frequency50-60Hz

Phase3 Phase

Capacity1000-30000 kg/day

Warranty1 year

Three Phase Automatic Mild Steel Glass Bottle Shredding Machine

Price: 160000 INR/Unit

MOQ1 Unit/Units

Processing TypeCrushing

Automatic GradeSemi

SizeStandard

Voltage440 Volt (v)

ColorBlue

Warranty1 Year

Glass Crusher

MaterialSteel

Dimensions150X100X200Cm

Power10Kw

Capacity100Kg/Hr

Weight500Kg

SafetyEmergency Stop

Electrically Operated Glass Bottle Shredder Machine - Mild Steel, 1000 - 30000 Kgs Per Day Capacity , Automatic Operation, Coated Surface Treatment, 1 Year Warranty

Price: 500000 INR/Unit

MOQ1 Unit/Units

Automatic GradeFully

ColorGreen

SizeStandard

Control SystemAutomatic

Frequency50 Hertz (HZ)

ApplicationIndustrial

Electrically Operated Glass Bottle Shredder Machine

Price: 240000 INR/Unit

MOQ1 Unit/Units

Automatic GradeSemi

Warranty1 Year

Control SystemSemi Automatic

Frequency50 Hertz (HZ)

ColorGreen

Voltage440 Volt (v)

Industrial Glass Bottle Shredder Machine

Price: 500000 INR/Unit

MOQ1 Unit/Units

Voltage440 Volt (v)

Control SystemAutomatic

Frequency50 Hertz (HZ)

ApplicationIndustrial

Automatic GradeFully

Warranty1 Year

Blue Heavy Duty Single Phase Glass Crusher Machine

Price: 90000 INR/Number

MOQ1 Set/Sets

ColorBlue

Product TypeGlass Crusher Machine

General UseGla

Steel Industrial Roll Impactor

Price Trend: 250000.00 - 1000000.00 INR/Unit

MOQ01 Unit/Units

Product TypeMachineries

General UseIndustrial

MaterialSteel

Capacityup to 15 TPH T/hr

ComputerizedNo

AutomaticNo

Automatic Glass Shredder - Mild Steel, 3 Phase, 380 V - 480 V, 1000 - 30000 Kgs Per Day Capacity | Electric, Semi-Automatic, 1 Year Warranty, Coated for Enhanced Durability

Body MaterialMild Steel

Driven TypeElectric

Voltage380-480V

Frequency50-60Hz

Phase3 Phase

Capacity1000-30000Kg/Day

Latest from Glass Crushers

Glass Crushers

By:

Proton Construction Machinery

Avanti Bs 400 Combo - Multipurpose Glass Crusher & Plastic Shredder 2 In 1 Combination

600000 INR

By:

Chanakya Docutel Systems

Plastic Glass Crusher Incinerator

By:

Zuci Fem Care Solutions

Low Maintenance Glass Crusher

By:

Aesha Conveyors And Crushing Equipment

Industrial Glass Crusher Machine

By:

Sahjanand Engineering

Reliable Mirror Glass Crusher

By:

Ramdev Crusher

How Glass Crushers Helps Increase Productivity and Efficiency?

Glass Crushers are mechanical devices that are specially designed to break glass products like bottles, jars, etc into fine particles for further processing, recycling, or disposal. To shatter the glass they are equipped with rotating hammers or blades inside, helping reduce their volume and making it possible to easily recycle. Most extensively they help in breaking down glasses for producing new glass-based products and minimize waste.

Major Applications of Glass Crushers:

-

Waste Management and Recycling Facilities

Glass crushers are extensively procured in the waste management and recycling industry for breaking down glass waste into fine particles to reduce their volume. All the waste generated through domestic, commercial and industrial activities are sourced here and by breaking it down the process of recycling and transportation becomes easy.

-

Hospitality and Food Service Industry

These mechanical equipment are most commonly hired in the food and hospitality industry for reducing the volume of glass waste produced by hotels, restaurants, resorts, bars, etc. Breaking process helps transport and process the glass waste easily.

-

Beverage Manufacturing

Glass crushers are used in beverage manufacturing facilities as they deal greatly in glass bottles for processing drinks. Glass crushers are hired for crushing the defective or used or excess bottles that are manufactured during the production process. Transforming them into glass cullets help companies to reuse the glass waste to recycle them into new bottles.

-

Glass Manufacturing

Glass crushers are hired in glass manufacturing facilities to break down glass cullets into granular form for remelting them into new products. Reusing these glass cullets is actually sustainable practice, as it reduces the need for more raw materials and energy consumption.

-

Construction and Building Materials

Glass crushers are extensively hired in the construction industry to make glass cullets that are used as raw materials for producing construction and building materials including glass aggregates, glass tiles, etc. This is the most beneficial sustainable effort due to which the need for using natural resources for construction is eliminated.

-

Landscaping and Decorative Applications

Glass crushers are commonly hired for waste and produce glass cullets, which are extensively used in landscaping work and outdoor decoration. These glass cullets are used for mulching, graveling, as aggregates for pathways, and gardens. Using recycled glass is not only a sustainable practice but also offers an aesthetic appearance to the property.

-

Art and Craft Supplies

Crushed glass cullet can be used by artists and crafters as a creative medium for various art and craft projects such as mosaics, sculptures, and jewelry making. Recycling glass waste into art supplies promotes sustainability and reduces environmental impact.

-

Educational and Awareness Initiatives

Glass crushers are utilized in educational settings and awareness campaigns to demonstrate the importance of recycling and waste reduction. Crushing glass bottles into cullets visually illustrates the process of recycling and encourages responsible waste management practices.

Major Benefits of Glass Crushers

-

Volume Reduction

Glass crushers significantly reduce the volume of glass waste by crushing glass bottles and jars into smaller pieces or cullet. This compacted form takes up less space in storage, transportation, and landfill disposal, reducing logistics costs and environmental impact.

-

Resource Conservation

By crushing and recycling glass waste, crushers help conserve natural resources such as sand, soda ash, and limestone, which are raw materials used in glass production. Recycling cullet reduces the need for extracting and processing these resources, conserving energy and reducing greenhouse gas emissions associated with glass manufacturing.

-

Environmental Protection

Glass crushers contribute to environmental protection by diverting glass waste from landfills and incinerators, where it can take hundreds or thousands of years to decompose. Recycling glass waste reduces landfill space usage, minimizes soil and water contamination, and prevents the release of harmful pollutants into the environment.

-

Energy Savings

Recycling glass cullet into new glass products requires less energy compared to manufacturing glass from raw materials. Glass crushers help reduce energy consumption and greenhouse gas emissions associated with the production of glass, contributing to energy savings and mitigating climate change.

-

Cost Efficiency

Glass crushers offer cost-effective waste management solutions for businesses, municipalities, and waste management facilities. By reducing the volume of glass waste and facilitating recycling, crushers lower waste disposal costs, transportation costs, and landfill tipping fees, resulting in overall cost savings.

-

Improved Recycling Rates

Glass crushers promote higher recycling rates by making glass recycling more convenient, efficient, and accessible. Crushing glass bottles onsite encourages recycling behavior among businesses, households, and institutions, leading to increased participation in recycling programs and diversion of glass waste from the waste stream.

-

Safety and Convenience

Glass crushers provide a safe and convenient method for handling glass waste, reducing the risk of injuries associated with manual handling and disposal of glass bottles and jars. Crushers offer a compact and efficient solution for businesses and facilities to manage glass waste onsite, improving operational efficiency and safety.

-

Promotion of Circular Economy

Glass crushers support the principles of a circular economy by closing the loop on the lifecycle of glass products. Recycling glass waste into new glass products creates a closed-loop system where materials are reused, reducing the need for virgin resources and minimizing waste generation, thus contributing to a more sustainable and circular economy.

How to Choose a Glass Crusher for Yourself?

Here’re the factors to consider while choosing a glass crusher for yourself:

- Capacity: Consider the volume of glass waste you generate daily to choose a crusher with the appropriate processing capacity.

- Size Reduction: Ensure the crusher can achieve the desired particle size or cullet to meet your recycling or disposal needs.

- Safety Features: Prioritize crushers with safety interlocks and guards to minimize the risk of accidents during operation.

- Durability: Select a crusher made from quality materials to withstand heavy-duty use and ensure long-term reliability.

- Maintenance: Choose a crusher with accessible components and easy-to-replace wear parts to facilitate routine maintenance and minimize downtime.

Glass Crushers Price List

This Data was Last Updated on 2025-10-07

Glass Crushers Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

D. P. Pulveriser Industries Mumbai, India | 24 Years |

Aesha Conveyors And Crushing Equipment Ahmedabad, India | 21 Years |

Miracle Marble Art Bhuj, India | 21 Years |

Amey Shredtech Private Limited Thane, India | 18 Years |

Micro Teknik Ambala Cantt, India | 13 Years |

Edutek Instrumentation Ambala Cantt, India | 11 Years |

Proton Construction Machinery Bhuj, India | 11 Years |

Raj Electricals Mumbai, India | 3 Years |

Industrial Engineers Vadodara, India | 3 Years |

Shredall Private Limited Mumbai, India | 2 Years |

Upcoming Tradeshows

SUBCONTRACT INDIA 2025

Thu, 06 Nov, 2025 - Sat, 08 Nov, 2025

Food AFair 2025

Fri, 14 Nov, 2025 - Sun, 16 Nov, 2025

Asia Labex 2025

Thu, 13 Nov, 2025 - Sat, 15 Nov, 2025

Fenestration Bau China 2025

Wed, 05 Nov, 2025 - Sat, 08 Nov, 2025

The Harit Bharat Expo 2026

Fri, 16 Jan, 2026 - Sun, 18 Jan, 2026

Paperex 2025

Wed, 03 Dec, 2025 - Sat, 06 Dec, 2025

Indian Ceramics Asia 2026

Wed, 28 Jan, 2026 - Fri, 30 Jan, 2026

IntraPac India 2025

Wed, 10 Dec, 2025 - Sat, 13 Dec, 2025

WORLD OF HOSPITALITY EXPO 2026

Thu, 29 Jan, 2026 - Sat, 31 Jan, 2026

ET TECH X 2025

Thu, 11 Dec, 2025 - Sat, 13 Dec, 2025

Popular Categories