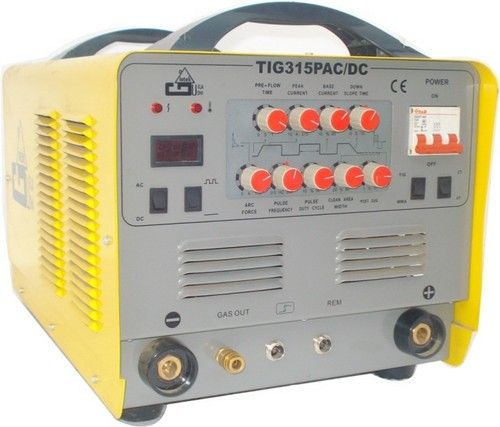

AC DC TIG welding machine USHA AC/DC TIG Welding Systems deliver high quality, surety and conformity to give you every reason to smile and showoff. The exactitude of quality standard IS: 1851 lies in its world class designing and engineering that took 3 years for our engineers to master. The result, a high performance innovation that saves you more, earns you more and lets you enjoy all the more. Recommended areas of use: Bicycle, fitness equipment, stainless furniture Maintenance and repair Industry Plant construction Companies Container manufactures Pipeline industry Non-source power factor compensation technology, high PF (power factor). High switch frequency, small size, light weight. Soft switch technology, high efficiency. HF arc-starting, stable arc, less spatter and excellent seam. Automatic arc force and hot start to perform perfect welding. Feature for AC/DC TIG welding, good looking weld, deep melting and low electrode consumption. Knob-control preset of all parameters and welding state, simple and convenient. Adjustable argon stopping time of lag, current descending time and the current of stopping arc improve the TIG welding performance. Excellent weld seam quality can be achieved due to its effect on all important areas of the weld. Self-diagnostic function with error code display. A type enjoys the synchronous mutual arc function. Recommended base metals: Mild steel, Stainless Steel Grades, Aluminum, Al Mg Alloys Etc Model GAD-200 Input voltage 220V15% Frequency 50/60 Hz Rate input Power 4.5 KVA Rate input current 16 Range of output current 10 to 200 Crater Filling Current 20 to 200 Up Slope Time 0.1 to 10 Down Slope Time 0.1 to 15 Pre-flow time 0-2 S Slope-down time 0-5 s Pulse Frequency 0.2 20 Pulse width 1-100 (%) Range of pulse frequency 1 70 (Hz) Welding Thickness 0.3 to 5 mm Efficiency 85 (%) Duty cycle 60 (%) 200 A Power factor (COS ) 0.93 Insulation class H Protection class IP21, IP23 Weight (Approx.) 18 KG. Measurement (Approx.) 560X361X360 mm