- Tradeindia

- Rubber & Rubber Products

- Conductive rubber sheets

- Conductive rubber sheets in Bengaluru

Conductive Rubber Sheets In Bengaluru

(1029 products)Conductive Sheets Ripple Springs Sheets

Product TypeConductive Sheets Ripple Springs Sheets

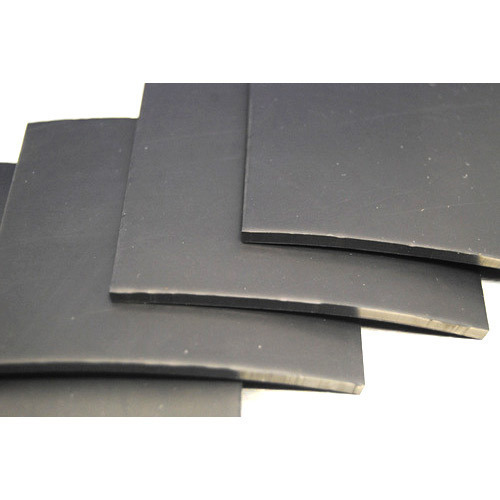

Conductive Rubber Sheet - Press Cured for Enhanced Durability | Ideal for Industrial, Decorative, and Agricultural Applications

Product DescriptionWe are providing our customers an excellent quality range of Conductive Rubber Sheets. Used in all kinds of instances from decorative to rubber sheeting flooring runners, industrial buildings, OEM parts, and other agricultural situations. This Conductive Rubber Sheet can be used anywhere that your a

Surface Resistivity Conductive Rubber Sheet - Ash %: 5% Max

Price: 1250 INR/Meter

MOQ10 Meter

Ash %5% Max

ColorBlack

StylePlain

Product TypeConductive Rubber Sheet

FeatureConductive Rubber Sheet Benefits Excellent conductivity on the entire surface Excellent electromagnetic shielding effect Easy die-cutting, kiss-cutting and slitting Temperature ranges of -60 to +185 AoC (under certain circumstances, tolerance can be up to 220AoC)

Hardness50 to 60

Sandhya Enterprises

Jeedimetla, Hyderabad

Trusted Seller

Trusted Seller4 Years

Premium Seller

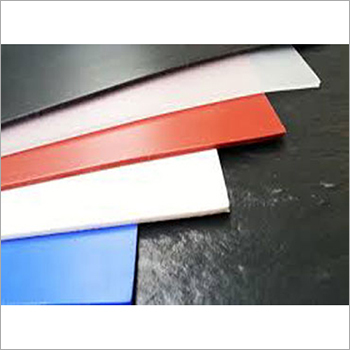

Premium SellerConductive Rubber Sheet - Ash %: 1%-5%

MOQ100 Meter

Ash %1%-5%

Natural RubberYes

Resistance levelHigh

ColorDifferent Available

HardnessRigid

FeatureHigh Quality

Progressive Rubber & Polymers Industry

Jeedimetla, Hyderabad

Conductive Rubber Sheets Grade: Industrial Grade

Product DescriptionOur organization is instrumental in manufacturing and supplying a premium gamut of Conductive Rubber Sheets. These offered sheets are manufactured by using premium quality rubber and advanced machinery in accordance with the defined industry norms. This sheets is well-known for its dimensional accur

Black Conductive Rubber Sheets

Product DescriptionOur organization is well recognized and identified as a major manufacturer and supplier a substantial selection of Conductive Rubber Sheets in Secunderabad, Telangana, India. These are manufactured using optimum grade material and emerging techniques under the visionary supervision of trained profes

Industrial Enterprises

Ranigunj, Secunderabad

Black Conductive Silicone Rubber Sheet

Price: 1750 INR/Square Foot

MOQ5000 Square Foot/Square Foots

Product NameConductive Silicone Rubber Sheet

MaterialRubber

ColorBlack

Electrically Conductive Silicone Rubber Sheet

Payment TermsCash in Advance (CID)

Main Domestic MarketAll India

Western Polyrub India Private Limited

Mumbai

Trusted Seller

Trusted Seller6 Years

Premium Seller

Premium SellerMultiple Industrial Rubber Sheets

Price: 400 INR/Kilograms

MOQ10 Kilograms/Kilograms

ColorMultiple

FeatureWater Resistance

Natural RubberSilicon

Diameter1.3 Centimeter (cm)

HardnessSoft

Thickness10 Millimeter (mm)

Shiwa Flex Enterprises

Kandivali West, Mumbai

conductive Rubber sheet

Payment TermsCash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

Sample PolicyWithin a certain price range free samples are available

Main Domestic MarketAll India

FAQs Related to Conductive Rubber Sheets In Bengaluru

How many conductive rubber sheets products are available in Bengaluru?

Where can I find conductive rubber sheets nearby Bengaluru?

What are some related categories to conductive rubber sheets in Bengaluru?

Can I trust the Bengaluru Based Conductive Rubber Sheets suppliers listed on Tradeindia?

How many Bengaluru based Conductive Rubber Sheets manufacturers are there?

What is the price range of conductive rubber sheets in Bengaluru?

| Company Name | Currency | Product Name | Price |

|---|---|---|---|

| - | - | Surface Resistivity Conductive Rubber Sheet | 1250 INR (Approx.) |

| - | - | Conductive Silicone Rubber Sheet | 1750 INR (Approx.) |

| - | - | Industrial Rubber Sheets | 400 INR (Approx.) |

| - | - | Black Rubber Sheets | 100 INR (Approx.) |

| - | - | Pu-High Abrasion Resistance Rubber Sheet | 550 INR (Approx.) |

| - | - | Electrical Rubber Sheet | 700.00 INR (Approx.) |

| - | - | Rubber Sheet | 220 INR (Approx.) |

| - | - | Black Rubber Sheets | 1028 INR (Approx.) |

| - | - | Electrical Rubber Sheet | 1130 INR (Approx.) |

What is the delivery time for conductive rubber sheets in Bengaluru?

How many trusted sellers are available for Conductive Rubber Sheets in Bengaluru?

Good Quality Black Rubber Sheets

Price: 100 INR/Kilograms

MOQ50 Kilograms/Kilograms

ColorBlack

HardnessSoft

FeatureGood Quality

Product TypeRubber Sheets

Fine Quality Electrical Rubber Sheet

MOQ50 Piece/Pieces

Payment TermsCash on Delivery (COD), Delivery Point (DP), Cash Against Delivery (CAD), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA)

Sample AvailableYes

Sample PolicyContact us for information regarding our sample policy

Rubber Sheet Ash %: 100

MOQ1 Piece/Pieces

Ash %100

ColorBlack

Product TypeRubber Sheet

StyleModern

Rabbit PU-High Abrasion Resistance Rubber Sheet

Price: 550 INR/Meter

MOQ100 Meter

FeatureDurable

StylePlain

ColorRed

Natural RubberNatural

Product TypePU-High Abrasion Resistance Rubber Sheet

Electrical Rubber Sheet - Color: Black

Price: 700.00 INR/Piece

MOQ10 , Piece/Pieces

Length10 Meter (m)

Resistance levelHigh

Thickness1- 25 Millimeter (mm)

ColorBlack

Natural RubberYes

Hardness60- 70 Shore A

Satyanarayan Rubber And Plastic Industries

Ahmedabad

Trusted Seller

Trusted Seller19 Years

Super Premium

Super PremiumRubber Sheet - Color: Black

Price: 220 INR/Kilograms

MOQ500 Kilograms/Kilograms

Product TypeIndustrial Rubber Sheet

ColorBlack

StyleNitrile

Tensile Strength17 Mpa Megapascals (MPa )

Thickness2 mm Millimeter (mm)

Natural RubberNitrile

Black Rubber Sheets - Hardness: Yes

Price: 1028 INR/Meter

MOQ10 Meter

StyleNoramal

Product TypeRubber Sheets

ColorBlack

HardnessYes

Natural RubberYes

Rubber Buffer For Lifts

Product DescriptionWe providing a wide range of Rubber Buffer For Lifts, which is fabricated using high quality raw material that is procured from reliable market vendors. Hence, these Rubber Buffer For Lifts can be purchased at competitive industrial rates

Rubber Safety Buttons For Lifts

Product DescriptionThese Safety Buttons For Lifts manufactured by us are capable of delivering longer service life and reliability to the users. These Rubber Safety Buttons For Lifts are fabricated using latest machines and technologies, which impart these with smooth finish, striking designs, and amazing thickness. T

Rubber Discharge Chute - Color: Black

Price: 500 INR/Piece

MOQ100 Piece/Pieces

Length1-15 Meter (m)

Product TypeRubber Sleeve

FeatureWeather Resistance

Hardness60 t 65 Shore A

ColorBlack

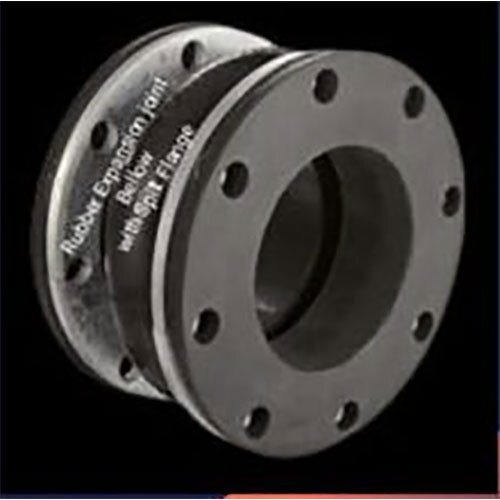

Rubber Expansion Joint With Spilet Flange - Ash %: 5% Max

Price: 3500 INR/Number

MOQ5 Number

ColorBlack

Ash %5% Max

Product TypeRubber Expansion Joint Bellow

FeatureRubber expansion joints, also known as rubber bellows or flexible connectors, are used in piping systems to absorb movement, reduce vibration, and compensate for thermal expansion and contraction. Here are some key features of rubber expansion joint bellows: 1. **Flexibility:** - Rubber expansion joints are highly flexible, allowing them to absorb axial, lateral, and angular movements in piping systems. This flexibility is essential for accommodating thermal expansion and contraction, vibrations, and misalignments. 2. **Material:** - Bellows are typically made from rubber compounds such as EPDM (ethylene propylene diene monomer), neoprene, or natural rubber. The material is chosen based on factors such as the type of fluid being conveyed and the operating conditions. 3. **Reinforcement:** - Some rubber expansion joints have reinforcement materials embedded in the rubber, such as fabric or metal rings, to enhance their strength and durability. 4. **Absorption of Movement:** - Axial Movement: Absorbs axial movement along the length of the expansion joint. - Lateral Movement: Accommodates lateral movement or misalignment of connected pipes. - Angular Movement: Allows for angular movement in different directions. 5. **Vibration Isolation:** - Rubber bellows help dampen vibrations in the piping system, reducing the transmission of noise and preventing damage to connected equipment. 6. **Corrosion Resistance:** - The rubber material used in expansion joints is often resistant to corrosion, making them suitable for use in various industrial environments. 7. **Temperature Resistance:** - Rubber expansion joints are designed to operate within a specified temperature range, ensuring their performance in both high and low-temperature applications. 8. **Pressure Rating:** - The expansion joint must have a pressure rating suitable for the specific application to prevent failure under varying pressure conditions. 9. **Absorption of Sound and Shock:** - Rubber bellows can help absorb sound and shock waves generated by the flow of fluids in the piping system, contributing to a quieter and more stable operation. 10. **End Connections:** - Expansion joints typically have flanged ends that can be bolted to the adjacent pipe or equipment. The flanges provide a secure connection and help maintain the integrity of the joint. 11. **Easy Installation:** - Rubber expansion joints are relatively easy to install, providing a cost-effective solution for accommodating movement and vibration in piping systems. 12. **Application Versatility:** - Rubber expansion joints find applications in various industries, including chemical processing, power generation, water treatment, HVAC, and more. 13. **Maintenance:** - Regular inspection and maintenance are recommended to check for signs of wear, fatigue, or damage. Timely replacement can prevent unexpected failures in the system. 14. **Compliance Standards:** - Expansion joints may need to comply with industry standards and regulations to ensure their safety and performance. Compliance helps guarantee that the joints meet certain quality and safety requirements. Selecting the right rubber expansion joint involves considering factors such as the type of fluid, temperature and pressure conditions, movement requirements, and the specific needs of the piping system. Consulting with manufacturers or experts in the field can aid in choosing the appropriate expansion joint for a particular application.

Resistance levelWeather Resistance

Hardness50 to 60

Cement Feeding Rubber Hose - Durable Rubber Construction, Flexible 4-Inch Diameter, Efficient Concrete Transport | Ideal for High-Rise Projects, Ready-Mix Plants, and Repair Applications

Price: 1800 INR/Meter

MOQ5 Meter

Payment TermsCash in Advance (CID)

Supply Ability5 Per Day

Delivery Time7 Days

Plain Rubber Sheet - Color: Black

Price: 1200.00 INR/Kilograms

MOQ100 Meter

FeatureWeather Resistance

Thickness2-7 Millimeter (mm)

Tensile Strength12 Megapascals (MPa )

ColorBlack

Product TypePlain Rubber Sheet

Is:7654 Chemical Rubber Hose - Ash %: 5% Max

Price: 1000 INR/Meter

MOQ100 Meter

Ash %5% Max

Resistance levelChemical Resistance

FeatureChemical rubber hoses are designed to handle the transfer of various chemicals, acids, and corrosive materials in industrial applications. The features of these hoses are crucial to ensure safety, reliability, and performance in conveying potentially hazardous substances. Here are some key features of chemical rubber hoses: 1. **Chemical Resistance:** - The primary feature of chemical rubber hoses is their resistance to a wide range of chemicals. These hoses are constructed from rubber compounds that can withstand the corrosive effects of acids, bases, solvents, and other aggressive substances. 2. **Material Composition:** - Chemical hoses are made from specialized rubber materials such as EPDM (ethylene propylene diene monomer), UHMW (ultra-high molecular weight) polyethylene, FKM (fluoroelastomer), or other chemical-resistant elastomers. The choice of material depends on the types of chemicals the hose will come into contact with. 3. **Reinforcement:** - Chemical hoses often feature reinforcement layers, which can include textile fabrics, wire helixes, or other materials. Reinforcements enhance the strength and durability of the hose, allowing it to withstand pressure and prevent kinking or collapse. 4. **Temperature Resistance:** - Chemical rubber hoses are designed to operate within specific temperature ranges. They should maintain their flexibility and structural integrity even in extreme temperatures, ensuring reliable performance in various industrial environments. 5. **Pressure Ratings:** - Hoses are rated for different pressure levels to suit various industrial processes. The pressure rating is an important consideration to ensure that the hose can handle the pressure requirements of the specific application. 6. **Flexibility:** - Chemical hoses need to be flexible to facilitate easy handling, installation, and maneuvering in different industrial settings. Flexible hoses are particularly important when working in confined spaces or when connecting to equipment with moving parts. 7. **End Connections:** - Chemical hoses typically have end connections, such as flanges or couplings, that allow them to be securely attached to equipment or other hoses in the system. Proper end connections help prevent leaks and ensure a secure transfer of chemicals. 8. **Color Coding:** - Some chemical hoses are color-coded to indicate their compatibility with specific types of chemicals. This helps users quickly identify the appropriate hose for a particular application and reduces the risk of cross-contamination. 9. **Static Dissipation:** - In applications where the transfer of chemicals may generate static electricity, chemical rubber hoses may include features to dissipate static charges, preventing the buildup of static electricity that could lead to sparks and potential hazards. 10. **Compliance Standards:** - Chemical hoses may need to comply with industry standards and regulations to ensure their safety and performance. Compliance with standards helps guarantee that the hose meets certain quality and safety requirements. 11. **Abrasion Resistance:** - Depending on the application, chemical hoses may be designed to resist abrasion, ensuring a longer service life, especially in environments where the hose may come into contact with abrasive materials. Choosing the right chemical rubber hose involves considering the specific requirements of the application, including the types of chemicals involved, temperature and pressure conditions, and other environmental factors. Consulting with manufacturers or industry experts can help ensure the selection of a hose that meets the necessary criteria for safety and performance.

StylePlain and Corrugated Top

ColorBlack

Product TypeChemical Rubber Hose

Grey Electrical Rubber Sheet

Price: 1130 INR/Meter

MOQ100 Meter

ColorGrey

Product TypeElectrical Rubber Sheet

Tensile Strength12 Mpa Megapascals (MPa )

Thickness2 Millimeter (mm)

LengthAs per available Meter (m)

Popular Categories in Bengaluru

Popular Products