Zero Liquid Discharge - Automatic Grade: Full Automatic

Price: 504668 INR / Unit

Get Latest Price

Minimum Order Quantity :

1 Unit

In Stock

Product Specifications

| Usage & Applications | Waste Water |

| Noise Level | 50 db |

| Feature | High Performance |

| Water Source | Other |

| Material | SS316L, Duplex, Titanium |

| Automatic Grade | Full Automatic |

| Drive Type | Electric |

| Voltage | 220 Volt (v) |

| Power Source | Electrical, Steam, Diesel, Gas |

| Payment Terms | Cash Advance (CA), Cash in Advance (CID) |

| Supply Ability | 5 Per Month |

| Delivery Time | 8 Week |

| Sample Policy | Contact us for information regarding our sample policy |

| Main Export Market(s) | Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East |

| Main Domestic Market | All India |

Product Overview

Key Features

A Zero Liquid Discharge (ZLD) Plant is an advanced wastewater treatment system designed to eliminate liquid waste discharge by recovering reusable water and converting effluent into solid waste. ZLD systems help industries comply with CPCB & SPCB norms while reducing freshwater consumption and environmental impact.

Our ZLD plants are custom-engineered to treat high-TDS, high-salinity industrial effluent, ensuring maximum water recovery and safe disposal of residues.

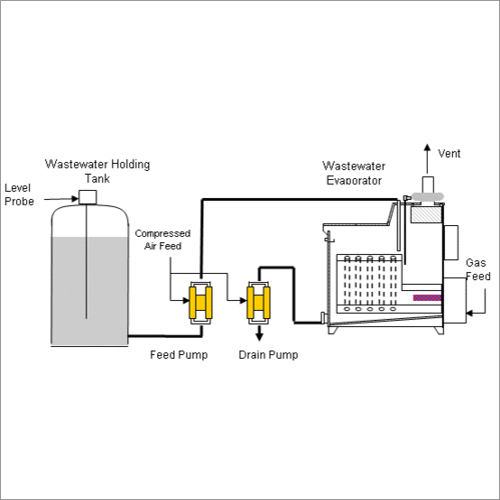

How a Zero Liquid Discharge Plant Works

A ZLD plant integrates multiple treatment technologies in stages:

Pre-Treatment AcA A Oil removal, pH correction, clarification

Biological / Chemical Treatment AcA A Reduction of COD & BOD

Membrane System (UF / RO) AcA A High water recovery

Evaporation System (MEE / MVR / TVR) AcA A Concentration of reject

Crystallizer / ATFD AcA A Conversion of liquid waste into dry salts

The recovered water is reused in process, cooling tower, or boiler feed, achieving 100% liquid discharge elimination.

Key Features of Our ZLD Plant

Up to 95 to A A 98% water recovery

Designed for high TDS & high chloride wastewater

Energy-efficient evaporation technology

Automated operation with PLC/SCADA

Low operating and maintenance cost

Robust construction with corrosion-resistant MOC

Scalable design for future expansion

Industries We Serve

Textile & Dyeing Units

Chemical & Pharmaceutical Industries

Food & Beverage Processing

Power Plants & Utilities

Automobile & Metal Finishing

FMCG & Specialty Chemicals

Industrial Parks & CETPs

Benefits of Zero Liquid Discharge System

Full compliance with environmental regulations

Zero wastewater disposal outside the plant

Significant reduction in freshwater intake

Lower long-term operating costs

Sustainable and eco-friendly operation

Improved corporate environmental responsibility

ZLD Plant Technologies We Offer

UF / RO based ZLD systems

Multiple Effect Evaporator (MEE)

Mechanical Vapor Recompression (MVR)

Thermal Vapor Recompression (TVR)

ATFD & Crystallizer systems

Customized hybrid ZLD solutions

Why Choose Us for ZLD Plant Solutions?

Proven expertise in industrial wastewater treatment

Custom-designed systems based on water analysis

High-quality equipment with long service life

End-to-end support: design, supply, installation & commissioning

Strong after-sales and AMC support

Our ZLD plants are custom-engineered to treat high-TDS, high-salinity industrial effluent, ensuring maximum water recovery and safe disposal of residues.

How a Zero Liquid Discharge Plant Works

A ZLD plant integrates multiple treatment technologies in stages:

Pre-Treatment AcA A Oil removal, pH correction, clarification

Biological / Chemical Treatment AcA A Reduction of COD & BOD

Membrane System (UF / RO) AcA A High water recovery

Evaporation System (MEE / MVR / TVR) AcA A Concentration of reject

Crystallizer / ATFD AcA A Conversion of liquid waste into dry salts

The recovered water is reused in process, cooling tower, or boiler feed, achieving 100% liquid discharge elimination.

Key Features of Our ZLD Plant

Up to 95 to A A 98% water recovery

Designed for high TDS & high chloride wastewater

Energy-efficient evaporation technology

Automated operation with PLC/SCADA

Low operating and maintenance cost

Robust construction with corrosion-resistant MOC

Scalable design for future expansion

Industries We Serve

Textile & Dyeing Units

Chemical & Pharmaceutical Industries

Food & Beverage Processing

Power Plants & Utilities

Automobile & Metal Finishing

FMCG & Specialty Chemicals

Industrial Parks & CETPs

Benefits of Zero Liquid Discharge System

Full compliance with environmental regulations

Zero wastewater disposal outside the plant

Significant reduction in freshwater intake

Lower long-term operating costs

Sustainable and eco-friendly operation

Improved corporate environmental responsibility

ZLD Plant Technologies We Offer

UF / RO based ZLD systems

Multiple Effect Evaporator (MEE)

Mechanical Vapor Recompression (MVR)

Thermal Vapor Recompression (TVR)

ATFD & Crystallizer systems

Customized hybrid ZLD solutions

Why Choose Us for ZLD Plant Solutions?

Proven expertise in industrial wastewater treatment

Custom-designed systems based on water analysis

High-quality equipment with long service life

End-to-end support: design, supply, installation & commissioning

Strong after-sales and AMC support

Company Details

Integro Process Heating Solutions (IPHS) was started in 2025 as a technology-driven engineering company dedicated to serving high-performance and energy-efficient thermal systems. It's our goal to design, engineer, and supply advanced process heating solutions for industry that improve productivity while decreasing cost and environmental impact.Integroa s founder, Mr. Anil Kumar Tufchi, an experienced industry veteran with over 30 years of extensive domain experience in power systems, comfort heating, solar and thermal process engineering, sees Integro as the culmination of a lifetime of experience and focus on innovation, technical ability and performance. Mr. Tufchia s career began with trading diesel gensets and designing and manufacturing acoustic enclosures. He then gravitated toward renewable energy and thermal

Business Type

Exporter, Importer, Manufacturer, Distributor, Supplier, Trading Company, Wholesaler, Retailer, Dealer, Fabricator, Producer

Employee Count

15

Establishment

2025

Working Days

Monday To Sunday

GST NO

09AALFI3700L1Z7

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 09AALFI3700L1Z7

Greater Noida, Uttar Pradesh

Director

Mr. Anil Tufchi

Members since

1 Years

Address

Plot No I 62, SITE-C, SURAJPUR INDUSTRIAL AREA, GREATER NOIDA, Greater Noida, Uttar Pradesh, 201306, India

wastewater evaporator in Greater Noida

Report incorrect details