Long Service Life Workshop On Gear Metrology

Price:

Get Latest Price

In Stock

Product Specifications

| Course Length | One day |

| Modules | Four |

| Topics Covered | Gear metrology, Calibration, Standards, Splines |

| Target Audience | Gear professionals |

| Learning Style | Interactive |

| Certification | Available |

| Usage | Improves gear manufacturing, testing and maintenance |

| Features | Gear knowledge, Error reduction, Noise minimized, Power increased, Failure reduced, Cost minimized |

Product Overview

Key Features

Workshop On Gear Metrology

Length of Course

One day.

Sessions

(Please contact for next available training program on following mail id or .)

Course Description

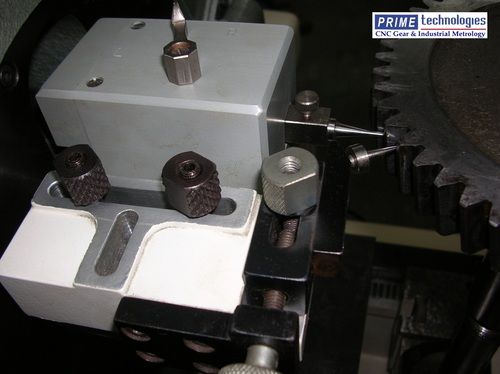

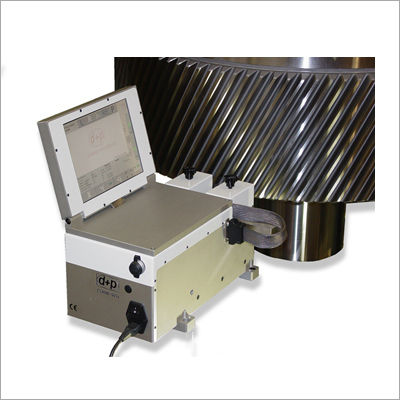

This comprehensive Onee day program provides a solid introduction for those new to the gear industry as well as an excellent review for experienced technologists. The Basic Gear Metrology module focuses on the involute helicoid system that is widely used for cylindrical

gears and splines. Composite and elemental measurement methods are described and contrasted. Categories, causes, and consequences of gear accuracy errors are discussed.The Calibration and Metrology module explores the subject of measurement validity beginning with discussion of important but often overlooked metrology issues. New traceability and calibration concepts are outlined. An introduction to statistical estimation of measurement uncertainty is included.The Gear Accuracy Standards module brings participants up to date with the recent changes in important AGMA and ISO documents.A Spline Measurement Module can also be included in the program.

Training groups are kept small so that individual concerns may be fully addressed

Benefits of the course on Gear Metrology

1. Identify why gears have failed - 90% of premature failures have excessive geometry errors

2. Identify the causes of manufacturing errors - we tell you what the results mean and how to correct them

3. Minimise noise from a gear set - poor specification or manufacture causes noise

4. Increase potential power density - accurate gears transmit more power

5. Prove your gears were supplied to specification

6. Reduce premature failure risks

7. Benchmark your suppliers manufacturing capability

8. Minimise product through life cost

9. Increase your competitiveness

Who should attend?

The course will be of benefit to those with some previous experience and also those who have recently become involved with gearing.

Company Details

Focusing on a customer-centric approach, Prime Technologies has a pan-India presence and caters to a huge consumer base throughout the country. Get Testing & Measuring Equipment from Prime Technologies at Trade India quality-assured services.

Business Type

Manufacturer, Service Provider, Supplier

Employee Count

25

Establishment

1991

Working Days

Monday To Sunday

GST NO

27AAEFP5924C1ZE

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AAEFP5924C1ZE

Mumbai, Maharashtra

Director

Mr Pramod S. Patil

Address

302, Bajsons Industrial Estate, Cardinal Gracious Road, Chakala, Andheri (East), Mumbai, Maharashtra, 400099, India

Report incorrect details