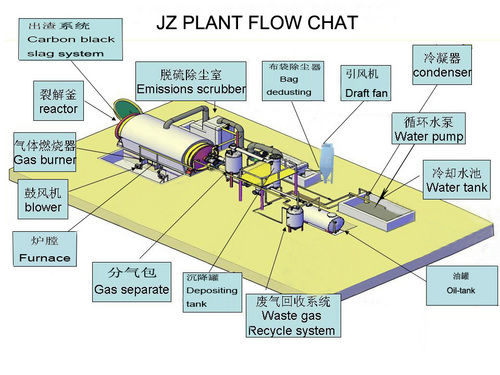

Waste Tyre Pyrolysis Plant - Steel Reactor Customized Dimensions 250-500°C Temperature Range | Eco-Friendly Oil Recovery High Efficiency Gas Generation Cost-Effective Simple Operation

Price:

Get Latest Price

In Stock

Product Specifications

| Reactor Material | Steel |

| Reactor Dimension | Customized |

| Oil Tank Capacity | Variable |

| Gas Burner Type | Industrial |

| Power Requirement | Variable |

| Temperature Range | 250-500C |

| Emissions Control | Scrubber |

| Features | Waste Recycling Oil Recovery Gas Generation Eco-Friendly Cost-Effective High Efficiency Simple Operation |

Product Overview

Key Features

Normal

0

false

false

false

EN-US

X-NONE

X-NONE

LatentStyleCount="267">

/* Style Definitions */

table.MsoNormalTable

{mso-style-name:"Table Normal";

mso-tstyle-rowband-size:0;

mso-tstyle-colband-size:0;

mso-style-noshow:yes;

mso-style-priority:99;

mso-style-qformat:yes;

mso-style-parent:"";

mso-padding-alt:0in 5.4pt 0in 5.4pt;

mso-para-margin-top:0in;

mso-para-margin-right:0in;

mso-para-margin-bottom:10.0pt;

mso-para-margin-left:0in;

line-height:115%;

mso-pagination:widow-orphan;

font-size:11.0pt;

font-family:"Calibri""sans-serif";

mso-ascii-font-family:Calibri;

mso-ascii-theme-font:minor-latin;

mso-fareast-font-family:"Times New Roman";

mso-fareast-theme-font:minor-fareast;

mso-hansi-font-family:Calibri;

mso-hansi-theme-font:minor-latin;}

Waste Tyre Pyrolysis Plant

We take immense pride to

introduce ourselves as one of the trustworthy service providers of Waste Tyre Pyrolysis Plant. These

pyrolysis services are offered by our experienced personnel as per the

requirements of the clients. Keeping in mind the details provided by the

clients these tyre pyrolysis plants are manufactured by using modern machines and

latest technology as per the international quality standards. We provide Waste Tyre Pyrolysis Plant at most reasonable prices. Further Details: JINGCHENG India has a team of experienced and expert renewable recycling consulting professionals that work hard for obtaining renewable energy from the waste & other alternative source of energy. Technology Pyrolysis involves heating organic materials without oxygen to break them down to simpler organic compounds. When organic wastes (e.g. waste tires) are the feedstock products of the process include char or carbon char oil and gas. For example pyrolysis can convert wood to charcoal and a low-Btu gas. Gasification of organics occurs at operating conditions between the complete absence of oxygen and stoichiometric (i.e. sufficient oxygen to complete the oxidation reaction). Gasification involves drying and pyrolyzing a feedstock and oxidizing the solid char to heat the reaction and provide carbon monoxide (CO) to the gas. In the early 1980s the waste industry saw gasification as promising. Gasification processes maximized the effect of carbon-hydrogen ratios. Furthermore the product gas was suitable for use in existing boilers / Gas Generators for Electricity Generation. Liquefaction is the thermochemical conversion of an organic solid into a petroleum-like liquid. Liquefaction typically involves the production of a liquid composed of heavy molecular compounds from a pyrolytic gas stream. The liquid has properties similar but not identical to those of petroleum-based fuels. Essentially liquefaction is manipulation of the pyrolysis process in order to produce a liquid with characteristics similar to petroleum-based liquids (e.g. fuel oils). Pyrolysis relies on the addition of heat to break chemical bonds providing a mechanism by which organics decompose and vaporize. Most projects operate within a temperature range of 250A a A A - 500A a A A C although some report operating at up to 900A a A A C. At temperatures above approximately 250A a A A C shredded tires release increasing amounts of liquid oil products and gases. Above 400A a A A C depending on the process employed the yield of oil and solid tire-derived char may decrease relative to gas production.. A typical commercial operation is described below. Tires delivered to a site are weighed. Tires are introduced to systems whole or else halvedchopped or shredded;Magnetic separation is often used to remove ferrous metals from size reduced tires. The feedstock is typically dried and preheated using tire-derived gas. Oxygen is purgedthrough a combination ofthe pyrolysis gas preheater and an inert gas system employing nitrogen. Temperature and residence time in the reactor are two key pyrolysis reactor design criteria.Maintaining a positivepressure in the reactor ensures that leaks do not introduce oxygen from the air. 4. The liquid stage tire-derived oil is condensed and cooled. Light and heavy oil fractions may be handled separately.A separator removes any remaining water vapor. The product is filtered. 5. Solid tire-derived char is cooled typically using a water-cooled stage. The product may be sized and screened toremove fiber. A magnetic separation stage captures magnetic materials remaining in the char. washing the char andfurther size reducing it produces the carbon black product. 6 Tire-derived gas maintains operating pressure in the system and provides heat to the system. Vented gases passthrough a pollution control train which may include a gas flare. 7 Gas can further treated for power generation. It is passes through venturi scrubber to remove particulate matter from gas and then it is passes through water cooled condenser which can help us to bring down the temperature oftire-derived gas and cracking of tar from it. Further it is passes through various filters containing wood waste andsaw dust waste to remove %moisture from gas and finally cleaned through fabric filter.Now our Gas is ultra cleanand can directly feed to Gas Driven Generating Set. But for continuous operation of generator we proposed low pressure vessel for the storage of gas. Through this storage power generation can be done for 24 hours irrespective of gas production rate through pyrolysis of waste tires. 8. Steel shreds are baled for shipment. Separated fibers when recovery is practical are baled for shipment. Oftenhowever fibers are disposed as waste. Energy Requirements JINGCHENG INDIA reports that the pyrolysis process produces an excess of energy. JINGCHENG India indicates that the combustion of tire-derived gas provides sufficient heat to drive the reaction. The use of supplemental fuel A AcAca A Aca A Scrap wood - is limited to the startup period. The electrical usage of systems is estimated to 12.8 kWh/ton of feedstock based on survey responses. The heat required to sustain the pyrolysis reaction appears to be between approximately 630 and 1025 Btu/lb of feedstock based on survey responses Features of the plant:- 1. 100% wastage tyre recycling is achieved (No churn left after the process) 2. No chemical ingredients are used in process (environment friendly) 3. During and after the process; no soil water or air pollution is observed. 4. Creates economically valuable products out of wastage tyres (These are an Industrial productthat have a good market value and demand) 5. The most cost-effective wastage tyre recycling technology ln the world. 6. Raw material (wastage tyre) is cheap and easy to provide. These are the by-products of tyre production. 7. Each recycled ton of tyres preserves 10 tons of CO2 that is a major green house gas. 8. It is a 100 % pollution free process thus making eco-friendly Environment. 9. The process can be applied to all rubber based materials. 10. The system creates an alternate source of energy to replace petroleum Products and naturalgas. 11. System gives the opportunity to governments and local administrations to deal with the wastage tyre problem to a great extent. 12. The process of Pyrolysis has duration of 4 to 12 hours depending onthe quantity and size of tyre (car tyre truck tyreetc.). During the process different vacuum values are applied in pre-determined temperatures and ln different phases. Different gases are obtained and the condensed gas is stored as a fuel oil in tanks. By-Products after Pyrolysis o Oil A A A a A A" 35% to 45% The mean ultimate analysis of pyrolytic oils is reported in following table. Also the mean heating value of oil is also provided. The ultimate analysis indicates an oil product well withinthe range of that of a fuel oil refined from crude oil. As per given below comparison. The main oil product produced by our recycling application is the fuel oil that is wide used for industrial and commercial purposes. The oil has 40% to 45% of the amount ofrecycled scrap tyres which will be carried with licensed tanker trucks. o Char and Carbon Black 30% to 40 % A solid product termed tire-derived char or tire-derived carbon char is produced by most Pyrolysis processes that use tires or other solid organic feedstock. The solid product can be further processed to enhance specific characteristics and to meet specifications for carbon black or can be marketed directly Virgin carbon black can reportedly be produced more economically and with better quality control than carbon black from tire char. Carbon black produced by Pyrolysis process (CBp) is more economical compared to carbon black produced primarily from petroleum and is more price-efficient to be used as an ingredient in the industries listed; A AcAca A A Ac Electric cable jacketing Conveyor band Carrier Bands Hose and doormat Black nylon bag Rubber additive Automotive spare parts Heat isolation Black colorant in rubber materials Plastic pipes Industrial rubber products Fire fighting Gas 12% to 15% The heating value of the gas is provided. The carbon content of the tire-derived gas is higher than that expected for most natural gas (i.e. 85.76 percent vs. approximately 70 - 75 percent) whereas the hydrogen content is lower (14.24 vs. 23 percent). Non-Condensable gases arise during the pyrolysis process. There are some advantages such as ... A AcAca A A Ac lt has higher calorific value as compared to natural gas. A AcAca A A Ac It can be replaced where natural gas and propane are stored. A AcAca A A Ac The high energy gas may be utilized as a source of energy for the Pyrolysis process. A AcAca A A Ac The amount of gas generated in the system is 12% to 15% of the total amount of recycled tyres and considering the 10 ton scrap tyre/day recycling capacity the facility generates 1200 -1500 m3/day gas which has an enormous energy potential when evaluated o Steel 10% to 12% Steel scrap extracted from the feedstock of the tire PGL process contains carbon and fiber contaminants but is usually considered a fairly clean scrap iron ready to be marketed. Valuable steel wires are pressed and sold to steel and scrap dealers.

Company Details

Focusing on a customer-centric approach JING CHENG (INDIA) has a pan-India presence and caters to a huge consumer base throughout the country. Get Plant & Machinery from JING CHENG (INDIA) at Trade India quality-assured services.

Business Type

Exporter, Importer, Manufacturer, Service Provider, Supplier

Employee Count

50

Establishment

2004

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

New Delhi, Delhi

Director

Mr. Vikram Krishna

Address

12 School Lane Near Bengali Market Barakhamba Road Opposite Hotel Lalit Connaught Place New Delhi Delhi 110001 India

Report incorrect details