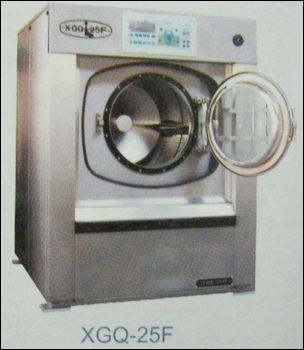

Washer Extractor (Xgq-50f)

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless steel |

| Dimensions | 1200x800x1500 mm |

| Capacity | 50kg |

| Power | 220V/380V |

| Speed | Variable |

| Water consumption | Low |

| Weight | 200kg |

| Features | High efficiency, Durable design, Easy operation, Quiet operation, Large capacity, Reliable performance, Time saving, Cost effective |

Product Overview

Key Features

Company Details

Focusing on a customer-centric approach, United Machines India Pvt. Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Laundry Equipment in bulk from United Machines India Pvt. Ltd. at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Establishment

2009

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Tirupur, Tamil Nadu

Director

Mr. Duraisamy Elangovan

Address

23, Ramaiah Colony 2nd Street, Ramaiya Colony East, Tirupur, Tamil Nadu, 641602, India

washer extractors in Tirupur

Report incorrect details