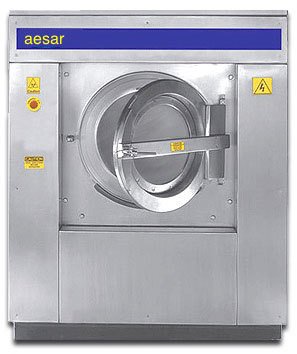

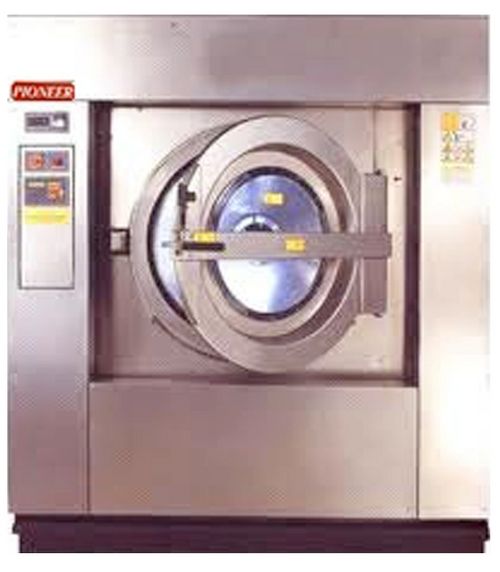

Washer Extractor - 30kg High Spin 350gs | Stainless Steel, Fully Automatic, Front Loading, Open Pocket, Ce & Gmp Certified

Price: 380000.00 INR / Unit

(380000.00 INR + 0% GST)

Get Latest Price

Minimum Pack Size :

1

In Stock

Product Specifications

| Color | Silver |

| Usage | Laundry |

| Heating | Electrical/Steam/Gas |

| Voltage | 220v/440/110 Watt (w) |

| Product Type | Washer Extractor for laundry |

| Weight | 500 Kilograms (kg) |

| Material | Stainless Steel |

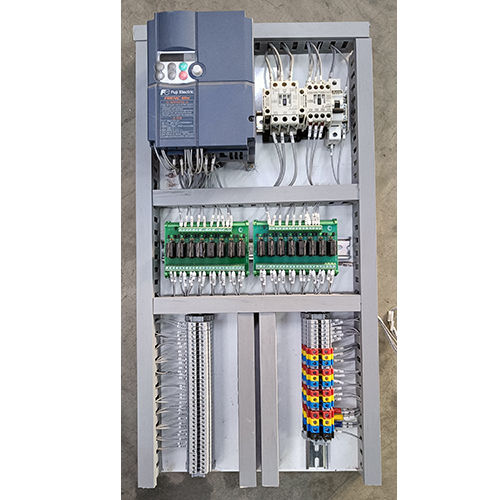

| Control System | Automatic |

| Installation Guideline | Yes |

| FOB Port | India |

| Supply Ability | 10 Per Week |

| Delivery Time | 20 Days |

| Sample Available | Yes |

| Sample Policy | Contact us for information regarding our sample policy |

| Main Domestic Market | All India |

| Certifications | We are an SSI, NSIC registered Company with AC/AEURAoeISO 9001-2015AC/AEUR Certification. We are happy to inform you that we have thousand of satisfied customers in India and over 18 Countries around the Globe. We are delighted to inform you that we are the First Indian Company in the field with GMP, World Health origination Certification & BMG,QMS,CE Certified by American National Standards Institute for 3 of our premier products and its entire range. |

| Product Unit | 1 Piece/Pieces |

| Stock Quantity | 5 |

| Unit Type | Piece/Pieces |

| Brand Name | Prachitirth Manufacturing Company |

| Returnable | No |

| Price | 380000.00 INR (Approx.) |

| Color | Silver |

| Currency | INR |

| Moq | 1 |

| Price Type | fixed |

| Mop | 1 |

| Minimum Order Quantity | 1 |

| Minimum Ordered Packs | 1 |

| GSTIN | 0% |

Product Overview

Key Features

Outstanding reliability and efficiency at a price you can afford The WE30 series is a breakthrough for suspended freestanding washer-extractors The advanced technological features used in this model have made it possible to make a machine that is easy to manufacture and operate at low cost. The WE30 models are the ultimate solution to savings in laundries as drying time, operating time utility consumption and labor expenses can be reduced significantly while increasing the productivity. Fully automatic, wash and High spin extract, Front loading, Open pocket, All Stainless Steel, Computer Controlled, Free Suspension.

WE30 WASHER EXTRACTOR 30KG HIGH SPIN 350Gs extracts force

INDIAa S FIRST a CEa & a GMPa certified Product

Company Details

Business Type

Manufacturer, Supplier

Employee Count

100

Establishment

2013

Working Days

Monday To Sunday

GST NO

24AAPFP1530P1ZW

Certification

ISO 9001:2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24AAPFP1530P1ZW

Rajkot, Gujarat

C.E.O.

Mr Prashant Rathod

Members since

3 Years

Address

2nd Floor, Coins Corner, Dr. Yagnik Road, Rajkot, Gujarat, 360001, India

washer extractors in Rajkot

Report incorrect details