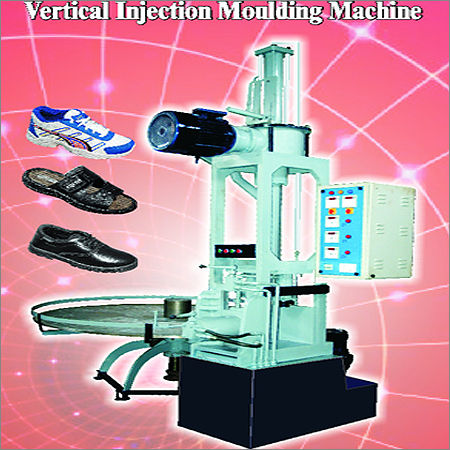

Vertical Toggle Plunger Fully Automatic

Price:

Get Latest Price

In Stock

Product Specifications

| Product Type | Injection Molding Machine |

| Dominant Color | Red |

| Moulding Capacity | 100 GMS |

| Plasticising Capacity | 6 Kg/Hr |

| Clamping Pressure | 18 tonne |

| Motor Power | 7.5 HP |

| Usage | Molding thermoplastic materials for automotive, cosmetic, and engineering components. |

| Features | Automatic operation, High efficiency, Durable design, Low maintenance, Versatile usage, Precise molding, Cost effective |

Product Overview

Key Features

Special Features

- Sturdy stable design

- Powerful hydraulic operated toggle clamp

- Die clamping direct cylinder

- High quality electric & hydraulic controls screw speed variable by hydraulic pump

- All hydraulic Components of standard quality are used for long life & Trouble-Free operation

- Fast and smooth cycles of operation.

- All Dies of hand-operationed machines can be used this machine

Fully / Semi Automatic Vertical Horizontal Plastic Injection Moulding Machines in many capacities.

Vertical Plastic Injection Moulding Machine-plunger Type

| Model | BBV-30 | BBV-40 | BBV-60 | BBV-100 | |

| Maximum Moulding Capacity | GMS | 30 | 40 | 60 | 100 |

| Maximum Plasticising capacity | Kg/Hr | 2 | 4 | 5 | 6 |

| Daylight Opening | MM | 150 | 200 | 350 | 400 |

| Minimum Mould Height | mm | 50 | 75 | 100 | 125 |

| Maximum Mould Size | mm | 75x75 | 100x100 | 150x150 | 200x200 |

| Mould Clamping Pressure | Tonne | 9 | 11.5 | 14.5 | 18 |

| Minimum No. of Strokes | P/HRS | 100 | 140 | 180 | 180 |

| Hydraulic Tank Capacity | LTRS | 100 | 120 | 150 | 180 |

| Electric Motor | HP | 3 | 5 | 5 | 7.5 |

| Heating Load | KW | 1 | 1.5 | 2 | 2.5 |

| Floor Space | FT | 5x2 1/2 | 5x2 1/2 | 6x3 | 6 x 3 1/2 |

| Height | FT | 7 | 7 | 8 | 9 |

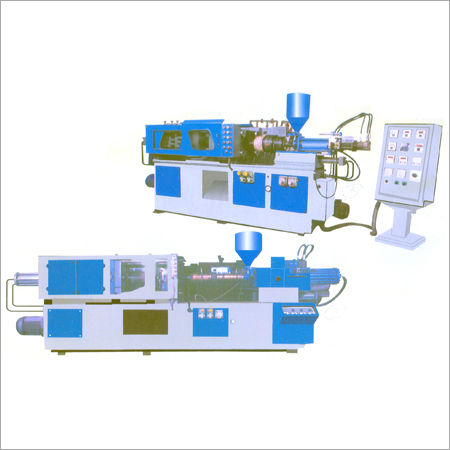

Vertical Screw Toggle Locking Injection Moulding Machine

| Injection Unit | Units | Injection Units | Units | ||

| Screw Diameter | mm | 28 | Maximum Mould Thickness | mm | 200 |

| L/D Ration | L/D | 16.1 | Minimum Mould Thickness | mm | 75 |

| Injection Rate | c.c./sec. | 42 | Maximum Area for Die Mounting | mm | 240x240 |

| Maximum Swept Volume | c.c. | 52 | Mould Clamping Load | tonnes | 5/3.7 |

| Shot Capacity (Polystyrene) | Gms/shot | 40 | Mould Platen Size | mm | 365x250 |

| Hopper Capacity | Ltr. | 5 | Electric | | |

| Screw Speed (Variable) with hydrometer | RPM | 10-190 | Electric Motor 3 Phase (1400 RPM) | H.P./KW | 2 |

| Injection Stoke with Hydromotor | mm | 100-10 | Heat controlled by pyrometer | no | 1 |

| Suckback | | | Heat controlled by Energy regulator | no | 3.5 |

| | | | Total Installed Power | k.w. | 7.2 |

| Optional | | | | ||

| Hydraulic Ejection Stroke | mm | 40 | General | ||

| Hydraulic Ejector Force | ton | 1 | Capacity of Oil Tank | Ltr | 100 |

| Clamping Unit | Weight (approx) | Ton | 1 | ||

| Maximum Day-light Opening | mm | 375 | | | |

| Maximum Mould Opening Stroke | mm | 175 | | | |

Company Details

Focusing on a customer-centric approach, B. B. N. HYDRAULIC WORKS has a pan-India presence and caters to a huge consumer base throughout the country. Get Injection Moulding Machine from B. B. N. HYDRAULIC WORKS at Trade India quality-assured services.

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Establishment

2005

Working Days

Monday To Sunday

GST NO

07CLDPK9413K1ZV

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 07CLDPK9413K1ZV

New Delhi, Delhi

Manager

Mr. Gulshan Kumar

Address

N-25, Shyam Nagar, Near Land Fresh, New Delhi, Delhi, 110018, India

Report incorrect details